Sugar facts for kids

Sugar is the common name for a number of chemical substances, some of which have a sweet taste. Mostly, it refers to either sucrose, lactose, or fructose. Sugar is contained in certain kinds of food, or it is added to give a sweet taste. Sugar is extracted from certain plants, such as sugarcane or sugar beet.

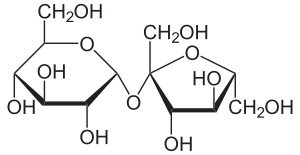

Regular sugar (the one commonly added to food) is called sucrose. Fructose is the sugar that is in fruits. As chemicals, sucrose and fructose are both made by two smaller sugars. Glucose is the more common of these smaller sugars. The human body changes regular sugar into the smaller sugars.

Sugars are a kind of carbohydrate. This is because sugars are made from carbon, hydrogen and oxygen. Carbohydrates can be simple carbohydrates or complex carbohydrates. Simple carbohydrates are made of only one or a few of the smallest sugars. Complex carbohydrates are made of many of the smallest sugars.

Starch is a chemical found in foods such as bread, crackers, and potatoes. It is a complex carbohydrate that is made from many glucose molecules. When starch is eaten, the human body breaks it apart into smaller sugars. An enzyme is added in the mouth, but it only begins to work in the stomach. Pure starch is actually tasteless in the mouth.

Brazil produces the most sugar per person and India's total consumption of sugar is the highest for a country.

There are other chemical substances that can be used to produce a sweet taste, but that are not sugar. One of them, commonly called Stevia is gained from a plant with the same name. Others, like aspartame, are completely synthetic. In general, these substances are known as artificial sweeteners, or sugar substitutes. People eat them to avoid health problems that sugar causes.

Sugar can be different colours. For example, brown sugar has molasses in it, and is often used in baking.

Contents

History

Ancient world to Renaissance

Asia

Sugar has been produced in the Indian subcontinent since ancient times and its cultivation spread from there into modern-day Afghanistan through the Khyber Pass. It was not plentiful or cheap in early times, and in most parts of the world, honey was more often used for sweetening. Originally, people chewed raw sugarcane to extract its sweetness. Sugarcane was a native of tropical Indian subcontinent and Southeast Asia.

Different species seem to have originated from different locations with Saccharum barberi originating in India and S. edule and S. officinarum coming from New Guinea. One of the earliest historical references to sugarcane is in Chinese manuscripts dating to 8th century BCE, which state that the use of sugarcane originated in India.

In the tradition of Indian medicine (āyurveda), the sugarcane is known by the name Ikṣu and the sugarcane juice is known as Phāṇita. Its varieties, synonyms and characteristics are defined in nighaṇṭus such as the Bhāvaprakāśa (1.6.23, group of sugarcanes). Sugar remained relatively unimportant until the Indians discovered methods of turning sugarcane juice into granulated crystals that were easier to store and to transport. Crystallized sugar was discovered by the time of the Imperial Guptas, around the 5th century CE. In the local Indian language, these crystals were called khanda (Devanagari: खण्ड, Khaṇḍa), which is the source of the word candy. Indian sailors, who carried clarified butter and sugar as supplies, introduced knowledge of sugar along the various trade routes they travelled. Traveling Buddhist monks took sugar crystallization methods to China. During the reign of Harsha (r. 606–647) in North India, Indian envoys in Tang China taught methods of cultivating sugarcane after Emperor Taizong of Tang (r. 626–649) made known his interest in sugar. China established its first sugarcane plantations in the seventh century. Chinese documents confirm at least two missions to India, initiated in 647 CE, to obtain technology for sugar refining. In the Indian subcontinent, the Middle East and China, sugar became a staple of cooking and desserts.

Europe

Nearchus, admiral of Alexander of Macedonia, knew of sugar during the year 325 B.C., because of his participation in the campaign of India led by Alexander (Arrian, Anabasis). The Greek physician Pedanius Dioscorides in the 1st century CE described sugar in his medical treatise De Materia Medica, and Pliny the Elder, a 1st-century CE Roman, described sugar in his Natural History: "Sugar is made in Arabia as well, but Indian sugar is better. It is a kind of honey found in cane, white as gum, and it crunches between the teeth. It comes in lumps the size of a hazelnut. Sugar is used only for medical purposes." Crusaders brought sugar back to Europe after their campaigns in the Holy Land, where they encountered caravans carrying "sweet salt". Early in the 12th century, Venice acquired some villages near Tyre and set up estates to produce sugar for export to Europe. It supplemented the use of honey, which had previously been the only available sweetener. Crusade chronicler William of Tyre, writing in the late 12th century, described sugar as "very necessary for the use and health of mankind". In the 15th century, Venice was the chief sugar refining and distribution center in Europe.

There was a drastic change in the mid-15th century, when Madeira and the Canary Islands were settled from Europe, and sugar grown there. After this an "all-consuming passion for sugar ... swept through society" as it became far more easily available, though initially still very expensive. By 1492, Madeira was producing over three million pounds weight of sugar annually. Genoa, one of the centers of distribution, became known for candied fruit, while Venice specialized in pastries, sweets (candies), and sugar sculptures. Sugar was considered to have "valuable medicinal properties" as a "warm" food under prevailing categories, being "helpful to the stomach, to cure cold diseases, and sooth lung complaints".

A feast given in Tours in 1457 by Gaston de Foix, which is "probably the best and most complete account we have of a late medieval banquet" includes the first mention of sugar sculptures, as the final food brought in was "a heraldic menagerie sculpted in sugar: lions, stags, monkeys ... each holding in paw or beak the arms of the Hungarian king". Other recorded grand feasts in the decades following included similar pieces. Originally the sculptures seem to have been eaten in the meal, but later they become merely table decorations, the most elaborate called triomfi. Several significant sculptors are known to have produced them; in some cases their preliminary drawings survive. Early ones were in brown sugar, partly cast in molds, with the final touches carved. They continued to be used until at least the Coronation Banquet for Edward VII of the United Kingdom in 1903; among other sculptures every guest was given a sugar crown to take away.

Modern history

In August 1492 Christopher Columbus stopped at La Gomera in the Canary Islands for wine and water, intending to stay only four days. He became romantically involved with the governor of the island, Beatriz de Bobadilla y Ossorio, and stayed a month. When he finally sailed, she gave him cuttings of sugarcane, which he carried to the New World. This was the introduction of this plant. The cuttings were planted and the first sugar-cane harvest in Hispaniola took place in 1501. Many sugar mills had been constructed in Cuba and Jamaica by the 1520s. The Portuguese took sugar cane to Brazil. By 1540, there were 800 cane-sugar mills in Santa Catarina Island and another 2,000 on the north coast of Brazil, Demarara, and Surinam.

Sugar was a luxury in Europe until the 18th century, when it became more widely available. It became highly popular and by the 19th century, sugar came to be considered a necessity. This evolution of taste and demand for sugar as an essential food ingredient resulted in major economic and social changes. Demand drove, in part, the colonization of tropical islands and areas where labor-intensive sugarcane plantations and sugar manufacturing could be successful. The demand for cheap labor to perform the labor-intensive cultivation and processing increased the demand for the slave trade from Africa (in particular West Africa).

After slavery was abolished, the demand for workers in the British Caribbean colonies was filled by indentured laborers from Indian subcontinent (in particular India). Millions of slave and indentured laborers were brought into the Caribbean and the Americas, Indian Ocean colonies, southeast Asia, Pacific Islands, and East Africa and Natal. Thus the modern ethnic mix of many nations that have been settled in the last two centuries has been influenced by the demand for sugar.

Sugar also led to some industrialization of areas where sugar cane was grown. For example, in the 1790s Lieutenant J. Paterson, of the Bengal establishment, promoted to the British Government the idea that sugar cane could grow in British India, where it had started, with many advantages and at less expense than in the West Indies. As a result, sugar factories were established in Bihar in eastern India. During the Napoleonic Wars, sugar-beet production increased in continental Europe because of the difficulty of importing sugar when shipping was subject to blockade. By 1880 the sugar beet was the main source of sugar in Europe. It was also cultivated in Lincolnshire and other parts of England, although the United Kingdom continued to import the main part of its sugar from its colonies.

Until the late nineteenth century, sugar was purchased in loaves, which had to be cut using implements called sugar nips. In later years, granulated sugar was more usually sold in bags. Sugar cubes were produced in the nineteenth century. The first inventor of a process to produce sugar in cube form was Moravian Jakub Kryštof Rad, director of a sugar company in Dačice. He began sugar-cube production after being granted a five-year patent for the process on January 23, 1843. Henry Tate of Tate & Lyle was another early manufacturer of sugar cubes at his refineries in Liverpool and London. Tate purchased a patent for sugar-cube manufacture from German Eugen Langen, who in 1872 had invented a different method of processing of sugar cubes.

Sugar was rationed during World War I and more sharply during World War II. This led to the development and use of various artificial sweeteners.

Production

Due to rising demand, sugar production in general increased some 14% over the period 2009 to 2018. The largest importers were China, Indonesia, and the United States.

Sugarcane

| Sugarcane production – 2016 | |

|---|---|

| Country | (millions of tonnes) |

| 768.7 | |

| 348.4 | |

| 122.7 | |

| 87.5 | |

| World | 1890.7 |

| Source: FAOSTAT, United Nations | |

Global production of sugarcane in 2016 was 1.9 billion tonnes, with Brazil producing 41% of the world total and India 18% (table).

Sugarcane refers to any of several species, or their hybrids, of giant grasses in the genus Saccharum in the family Poaceae. They have been cultivated in tropical climates in the Indian subcontinent and Southeast Asia over centuries for the sucrose found in their stems. A great expansion in sugarcane production took place in the 18th century with the establishment of slave plantations in the Americas. The use of slavery for the labor-intensive process resulted in sugar production, enabling prices cheap enough for most people to buy. Mechanization reduced some labor needs, but in the 21st century, cultivation and production relied on low-wage laborers.

Sugar cane requires a frost-free climate with sufficient rainfall during the growing season to make full use of the plant's substantial growth potential. The crop is harvested mechanically or by hand, chopped into lengths and conveyed rapidly to the processing plant (commonly known as a sugar mill) where it is either milled and the juice extracted with water or extracted by diffusion. The juice is clarified with lime and heated to destroy enzymes. The resulting thin syrup is concentrated in a series of evaporators, after which further water is removed. The resulting supersaturated solution is seeded with sugar crystals, facilitating crystal formation and drying. Molasses is a by-product of the process and the fiber from the stems, known as bagasse, is burned to provide energy for the sugar extraction process. The crystals of raw sugar have a sticky brown coating and either can be used as they are, can be bleached by sulfur dioxide, or can be treated in a carbonatation process to produce a whiter product. About 2,500 litres (660 US gal) of irrigation water is needed for every one kilogram (2.2 pounds) of sugar produced.

Sugar beet

| Sugar beet production – 2016 | |

|---|---|

| Country | (millions of tonnes) |

| 51.4 | |

| 33.8 | |

| 33.5 | |

| 25.5 | |

| 19.5 | |

| World | 277.2 |

| Source: FAOSTAT, United Nations | |

In 2016, global production of sugar beets was 277 million tonnes, led by Russia with 19% of the world total (table).

The sugar beet became a major source of sugar in the 19th century when methods for extracting the sugar became available. It is a biennial plant, a cultivated variety of Beta vulgaris in the family Amaranthaceae, the tuberous root of which contains a high proportion of sucrose. It is cultivated as a root crop in temperate regions with adequate rainfall and requires a fertile soil. The crop is harvested mechanically in the autumn and the crown of leaves and excess soil removed. The roots do not deteriorate rapidly and may be left in the field for some weeks before being transported to the processing plant where the crop is washed and sliced, and the sugar extracted by diffusion. Milk of lime is added to the raw juice with calcium carbonate. After water is evaporated by boiling the syrup under a vacuum, the syrup is cooled and seeded with sugar crystals. The white sugar that crystallizes can be separated in a centrifuge and dried, requiring no further refining.

Refining

Refined sugar is made from raw sugar that has undergone a refining process to remove the molasses. Raw sugar is sucrose which is extracted from sugarcane or sugar beet. While raw sugar can be consumed, the refining process removes unwanted tastes and results in refined sugar or white sugar.

The sugar may be transported in bulk to the country where it will be used and the refining process often takes place there. The first stage is known as affination and involves immersing the sugar crystals in a concentrated syrup that softens and removes the sticky brown coating without dissolving them. The crystals are then separated from the liquor and dissolved in water. The resulting syrup is treated either by a carbonatation or by a phosphatation process. Both involve the precipitation of a fine solid in the syrup and when this is filtered out, many of the impurities are removed at the same time. Removal of color is achieved by using either a granular activated carbon or an ion-exchange resin. The sugar syrup is concentrated by boiling and then cooled and seeded with sugar crystals, causing the sugar to crystallize out. The liquor is spun off in a centrifuge and the white crystals are dried in hot air and ready to be packaged or used. The surplus liquor is made into refiners' molasses.

The International Commission for Uniform Methods of Sugar Analysis sets standards for the measurement of the purity of refined sugar, known as ICUMSA numbers; lower numbers indicate a higher level of purity in the refined sugar.

Refined sugar is widely used for industrial needs for higher quality. Refined sugar is purer (ICUMSA below 300) than raw sugar (ICUMSA over 1,500). The level of purity associated with the colors of sugar, expressed by standard number ICUMSA, the smaller ICUMSA numbers indicate the higher purity of sugar.

Forms and uses

Crystal size

- Misri or mishri refers to large crystallized sugar lumps. It has its origins in India and Iran, where it is used either as a candy or as a sweetener for beverages such as milk, coffee and tea. In Hinduism, misri may be offered to a deity or distributed to worshippers after worship.

- In Western Countries, misri is known as rock candy, sugar candy or rock sugar, not to be confused with the amorphous (i.e. non crystalline) and opaque British sugar confection called rock, initially hard but then chewy at mouth temperature. Food coloring may be added to the mixture to produce colored candy.

- Coarse-grain sugar, also known as sanding sugar, composed of reflective crystals with grain size of about 1 to 3 mm, similar to kitchen salt. Used atop baked products and candies, it will not dissolve when subjected to heat and moisture.

- Granulated sugar (about 0.6 mm crystals), also known as table sugar or regular sugar, is used at the table, to sprinkle on foods and to sweeten hot drinks (coffee and tea), and in home baking to add sweetness and texture to baked products (cookies and cakes) and desserts (pudding and ice cream). It is also used as a preservative to prevent micro-organisms from growing and perishable food from spoiling, as in candied fruits, jams, and marmalades.

- Milled sugars are ground to a fine powder. They are used for dusting foods and in baking and confectionery.

- Caster sugar, sold as "superfine" sugar in the United States, with grain size of about 0,35 mm

- Powdered sugar, also known as confectioner's sugar or icing sugar, available in varying degrees of fineness (e.g., fine powdered or 3X, very fine or 6X, and ultra-fine or 10X). The ultra-fine variety (sometimes called 10X) has grain size of about 0.060 mm, that is about ten times smaller than granulated sugar.

- Snow powder, a non-melting form of powdered sugar usually consisting of glucose, rather than sucrose.

- Screened sugars are crystalline products separated according to the size of the grains. They are used for decorative table sugars, for blending in dry mixes and in baking and confectionery.

Shapes

- Sugar cubes() (sometimes called sugar lumps) are white or brown granulated sugars lightly steamed and pressed together in block shape. They are used to sweeten drinks.

- Sugarloaf was the usual cone-form in which refined sugar was produced and sold until the late 19th century. This shape is still in use in Germany (for preparation of Feuerzangenbowle) as well as Iran and Morocco.

Brown sugars

Brown sugars are granulated sugars, either containing residual molasses, or with the grains deliberately coated with molasses to produce a light- or dark-colored sugar. They are used in baked goods, confectionery, and toffees. Their darkness is due to the amount of molasses they contain. They may be classified based on their darkness or country of origin. For instance:

- Light brown, with little content of molasses (about 3.5%)

- Dark brown, with higher content of molasses (about 6.5%)

- Non-centrifugal cane sugar, unrefined and hence very dark cane sugar obtained by evaporating water from sugarcane juice, such as:

- Panela, also known as rapadura, chancaca or piloncillo.

- Some varieties of muscovado, also known as Barbados sugar. Other varieties are partially refined by centrifugation or by using a spray dryer.

- Some varieties of jaggery. Other varieties are produced from date fruits or from palm sap, rather than sugarcane juice.

Liquid sugars

- Honey, mainly containing unbound molecules of fructose and glucose, is a viscous liquid produced by bees by digesting floral nectar.

- Syrups are thick, viscous liquids consisting primarily of a solution of sugar in water. They are used in the food processing of a wide range of products including beverages, hard candy, ice cream, and jams.

- Syrups made by dissolving granulated sugar in water are sometimes referred to as liquid sugar. A liquid sugar containing 50% sugar and 50% water is called simple syrup.

- Syrups can also be made by reducing naturally sweet juices such as cane juice, or maple sap.

- Corn syrup is made by converting corn starch to sugars (mainly maltose and glucose).

- High-fructose corn syrup (HFCS), is produced by further processing corn syrup to convert some of its glucose into fructose.

- Inverted sugar syrup, commonly known as invert syrup or invert sugar, is a mixture of two simple sugars—glucose and fructose—that is made by heating granulated sugar in water. It is used in breads, cakes, and beverages for adjusting sweetness, aiding moisture retention and avoiding crystallization of sugars.

- Molasses and treacle are obtained by removing sugar from sugarcane or sugar beet juice, as a byproduct of sugar production. They may be blended with the above-mentioned syrups to enhance sweetness and used in a range of baked goods and confectionery including toffees and licorice.

- Blackstrap molasses, also known as black treacle, has dark color, relatively small sugar content and strong flavour. It is sometimes added to animal feed, or processed to produce rum, or ethanol for fuel.

- Regular molasses and golden syrup treacle have higher sugar content and lighter color, relative to blackstrap.

- In winemaking, fruit sugars are converted into alcohol by a fermentation process. If the must formed by pressing the fruit has a low sugar content, additional sugar may be added to raise the alcohol content of the wine in a process called chaptalization. In the production of sweet wines, fermentation may be halted before it has run its full course, leaving behind some residual sugar that gives the wine its sweet taste.

Other sweeteners

- Low-calorie sweeteners are often made of maltodextrin with added sweeteners. Maltodextrin is an easily digestible synthetic polysaccharide consisting of short chains of three or more glucose molecules and is made by the partial hydrolysis of starch. Strictly, maltodextrin is not classified as sugar as it contains more than two glucose molecules, although its structure is similar to maltose, a molecule composed of two joined glucose molecules.

- Polyols are sugar alcohols and are used in chewing gums where a sweet flavor is required that lasts for a prolonged time in the mouth.

- Several different kinds of zero-calorie artificial sweeteners may be also used as sugar substitutes.

Consumption

In most parts of the world, sugar is an important part of the human diet, making food more palatable and providing food energy. After cereals and vegetable oils, sugar derived from sugarcane and beet provided more kilocalories per capita per day on average than other food groups. According to one source, per capita consumption of sugar in 2016 was highest in the United States, followed by Germany and the Netherlands.

Related pages

Images for kids

-

Still-Life with Bread and Confectionery, by George Flegel, first half of 17th century

See also

In Spanish: Azúcar para niños

In Spanish: Azúcar para niños