Sawmill facts for kids

A sawmill is a special place where big logs from trees are cut into useful pieces of wood. These pieces are called lumber or boards. Sawmills help turn trees into materials we use to build houses, furniture, and many other things.

Contents

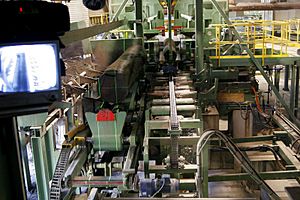

How Sawmills Work Today

Modern sawmills still follow a process similar to those from hundreds of years ago. A large tree log goes in one end, and finished pieces of wood come out the other.

Here are the main steps:

- Choosing Trees: First, specific trees are selected to be cut down.

- Felling: The chosen tree is cut so it falls over. This is called felling.

- Bucking: The tree trunk is cut into exact lengths needed for the sawmill.

- Limbing: All the branches are cut off the main tree trunk.

- Transport: The logs are then moved to the sawmill. This can be by special trucks, trains, or even by floating them down rivers.

- Measuring: Workers called log scalers measure the logs. This happens either on the way to the mill or when they arrive.

- Debarking: The bark is removed from the logs.

- Sorting: Logs are sorted by their type of wood, size, and what they will be used for (like lumber or wood chips).

Cutting and Finishing the Wood

After sorting, the logs go through several cutting and finishing steps:

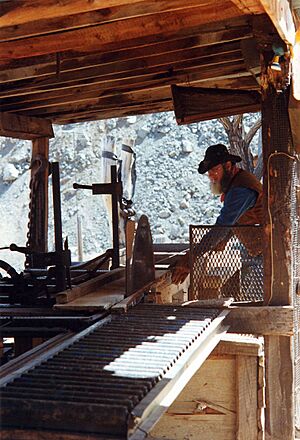

- Primary Sawing: A skilled worker called a sawyer uses a large saw to cut the log into smaller pieces. These smaller pieces are called cants (smaller logs) and flitches (unfinished planks).

- Further Cutting: Depending on the wood type, the cants are cut even smaller by other saws. They become more flitches or boards.

- Edging: Machines trim off any uneven edges from the flitches. This makes sure the wood has four straight sides.

- Trimming: The ends of the wood pieces are cut square. This makes them the standard lengths for lumber.

- Drying: The natural moisture is removed from the wood. This can be done by drying it in special ovens called kilns or by air-drying it outside.

- Planing: The surface of the wood is smoothed. This makes sure the wood has a uniform width and thickness.

- Shipping: Finally, the finished wood is sent to stores or construction sites.

Sawmills Through History

Sawmills have been around for a very long time. People believe they existed in the Middle Ages, with one even sketched around the year 1250. They became more common in Europe in the 1500s.

Before sawmills, two strong men would cut boards by hand using a large saw called a whipsaw. One man stood on top of the log, and the other stood in a pit below. This was very slow and hard work. The man on top, called the topsawyer, had to be stronger. He also had to guide the saw to make sure the board was the same thickness.

Early Inventions

A Dutch inventor named Cornelis Corneliszoon made an important improvement in the late 1500s. He figured out how to use a windmill to power a sawmill. He used a special part called a pitman arm. This arm changed the windmill's spinning motion into an up-and-down motion for the saw blade. He received patents for his inventions in 1593 and 1597.

Early sawmills often used water wheels instead of windmills. These wheels also changed their circular motion into the back-and-forth movement needed for the saw. At first, only the saw blade was powered. Workers still had to load and move the logs by hand. Later, a moving carriage was invented, also powered by water, to feed the log steadily through the saw.

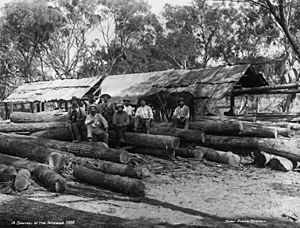

Small sawmills like these were important in many rural areas that produced wood, such as Canada. They often only ran during winter, which was the best time for cutting down trees. Their output was quite low, perhaps only 500 boards a day.

Sawmills in America

Sawmills arrived in the United States soon after the first settlements in Virginia. Skilled workers from Germany helped set them up. The metal parts for the mills often came from the Netherlands, which had more advanced technology than England at the time. When a sawmill came to a new frontier community, it helped the community grow a lot.

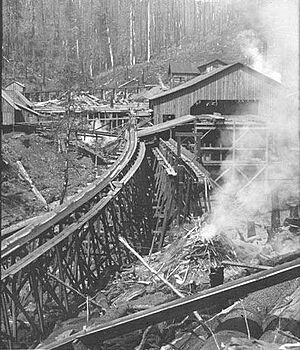

At first, mills were often built temporarily in the forest. Logs were pulled to the mill by horses or oxen, especially when there was snow to make it easier. As mills grew bigger, they were built in more permanent spots, usually by a river. Logs could then be floated down the river to the mill.

Today, technology has greatly changed how sawmills work. They focus on wasting less wood and using energy more efficiently. They also make sure workers are safer.

Images for kids

See also

In Spanish: Aserradero para niños

In Spanish: Aserradero para niños