Flax facts for kids

Quick facts for kids Flax |

|

|---|---|

|

|

| Common Flax | |

| Scientific classification | |

| Kingdom: | |

| Division: | |

| Class: | |

| Order: | |

| Family: | |

| Genus: | |

| Species: |

L. usitatissimum

|

| Binomial name | |

| Linum usitatissimum |

|

Flax, also called common flax or linseed, is a super useful plant. Its scientific name is Linum usitatissimum. People use the strong fibers from flax to make linen fabric. This fabric is used for clothes, sheets, and more! Flax fibers are also used to make special, strong paper, like the kind used for banknotes (money!). You can also get an oil called linseed oil from the dried seeds of the flax plant. For a very long time, flax has helped people make things like bows and candles.

Contents

What Does Flax Look Like?

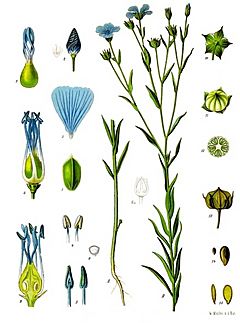

Cultivated flax plants can grow up to 1.2 meters (about 4 feet) tall. They have thin, slender stems. The leaves are a greenish-blue color. They are long and narrow, about 20–40 mm long and 3 mm wide.

Flax flowers are a pretty pale blue. Each flower is about 15–25 mm wide and has five petals. The fruit of the flax plant is a round, dry pod. It is 5–9 mm wide and holds several shiny brown seeds. These seeds look a bit like tiny apple seeds.

The Long History of Flax

Flax has been used by humans for a very long time. The oldest proof of people using wild flax is from the country of Georgia. About 30,000 years ago, people there found spun, dyed, and tied wild flax fibers in a cave. This shows how ancient flax use is!

Flax was first grown by people in the Fertile Crescent area. This is a region in the Middle East. About 9,000 years ago, people in Syria were growing a type of flax with bigger seeds for oil. The use of flax slowly spread. It reached places like Switzerland and Germany about 5,000 years ago. In China and India, people also grew domesticated flax at least 5,000 years ago.

Flax was very important in ancient Egypt. Paintings of flowering flax plants were on temple walls. Even mummies were wrapped in linen cloth made from flax. Egyptian priests only wore linen because flax was a symbol of purity. Phoenicians traded Egyptian linen all around the Mediterranean. The Romans used linen for their sails.

After the Roman Empire became weaker, flax farming also slowed down. But a ruler named Charlemagne helped bring flax back in the 700s CE. He made laws to encourage people to use linen for cleanliness and linseed oil for health. Later, Flanders (in modern-day Belgium) became a major center for making linen in Europe during the Middle Ages.

When colonists came to North America, they brought flax with them. It grew very well there. However, by the early 1900s, cotton became cheaper and easier to get. Also, farm wages went up. Because of this, most flax production moved to northern Russia. Russia ended up producing 90% of the world's flax. Today, flax is not as important as a commercial crop as it once was. This is because other strong fibers are now easy to find.

How We Use Flax Today

Flax is grown for its oil, which is used in many ways. It can be a healthy food supplement. It's also an ingredient in products that finish wood, like varnishes. Sometimes, flax is grown just as a pretty ornamental plant in gardens. The Latin name for flax, usitatissimum, means "most useful." This shows how important it is!

Flax Fibers and Linen

Flax fibers come from the stem of the plant. They are two to three times stronger than cotton fibers. Also, flax fibers are naturally smooth and straight. Before the 1800s, Europe and North America relied on flax for plant-based cloth. Then, cotton became more popular for making paper and cloth.

Flax is grown in Canada for linseed oil. This oil is used in paints, varnishes, and products like linoleum. It's also used in printing inks. In India, flax seed oil is called alsi or javas. It's mainly used in certain curries, like mutton curries.

After the oil is taken from flax seeds, the leftover part is called linseed meal. This meal is used to feed farm animals. It's a good source of protein for animals like cows, rabbits, and fish.

Flaxseeds and Their Uses

Flaxseeds come in two main types: brown and yellow (or golden). Most types have similar healthy nutrients and omega-3 fatty acids. One exception is a yellow flax called solin, which has very little omega-3.

Flaxseeds produce a vegetable oil called flaxseed oil or linseed oil. This is one of the oldest oils used by people. It's an edible oil made by pressing the seeds. For many centuries, flaxseed oil has been used in painting and varnishing because it dries well.

Brown flaxseeds can be eaten, and people have eaten them for thousands of years. However, they are more commonly known for their use in paints, fibers, and animal feed.

Eating Flaxseeds

A 100-gram serving of ground flaxseed has about 534 calories. It also contains 41 grams of fat, 28 grams of fiber, and 20 grams of protein. Flaxseed sprouts can be eaten too, and they have a slightly spicy taste. In northern India, flaxseed (called tisi or alsi) is often roasted and ground into a powder. People eat it with boiled rice, a little water, and salt.

Whole flaxseeds stay fresh for a long time. But ground flaxseed can go rancid (spoil) quickly. This happens if it's left out in the air at room temperature for just a week. This is because of a process called oxidation.

Processing Flax

To get the useful flax fibers, they must be separated from the rest of the plant stem. First, the seeds are removed from the plant. This process is called Threshing. Then, the stems are pulled through a tool called a hackle. They can also be beaten to break them apart.

Flax processing has two main parts. The first part is usually done by the farmer. This prepares the flax fiber for general uses. Three machines can help with this:

- One machine removes the seeds.

- Another machine breaks and separates the straw (stem) from the fiber.

- A third machine further separates the broken straw from the fiber.

The second part of the process prepares the flax for very fine uses. This includes making lace, cambric, damask, and very fine linen. This second part is done with a special refining machine.

Here are some old steps for processing flax by hand:

- Hold small handfuls of flax in your left hand. Spread it flat between your fingers.

- Put the handful into the breaking machine. Gently beat it until the first few inches feel soft.

- Move the flax higher in your hand. Keep beating it until all of it is soft. The woody part should separate from the fiber.

- Then, turn the flax around. Wrap the beaten end around your little finger. Beat the other end until the wood separates, just like the first end.

Preparing Flax for Spinning

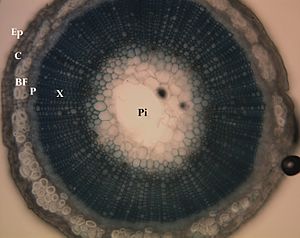

Before flax fibers can be spun into linen, they must be separated from the stalk. The first step is called retting. This is a process that rots away the inner stalk. It leaves the outer parts, which contain the fibers, mostly whole. At this point, some coarse outer stem parts (like the cortex and epidermis) are still there. To remove these, the flax is "broken." The straw breaks into small pieces, but the actual fiber stays unharmed. Then, Scutching scrapes the outer straw away from the fiber. Finally, the stems are pulled through "hackles." These are like combs that remove any leftover straw and shorter fibers from the long fibers.

Retting Flax

There are several ways to ret flax. It can be retted in a pond, stream, field, or tank. When the retting is finished, the bundles of flax feel soft and slimy. Many fibers will be sticking out from the stalks. If you wrap a fiber around your finger, the inner woody part should easily spring away from the fibers.

In field retting, the flax is spread out in a large field. Dew (moisture from the air) collects on it. This process usually takes a month or more. But it often gives the highest quality flax fibers. It also causes the least pollution.

Retting can also be done in a plastic trash can or any water-tight container made of wood, concrete, or plastic. Metal containers won't work because retting produces an acid that would corrode the metal.

Dressing the Flax

Dressing the flax is the process of removing the straw from the fibers. Dressing has three steps: breaking, scutching, and heckling.

- Breaking makes the straw break into short pieces.

- Scutching scrapes some of the straw away from the fiber.

- Heckling is pulling the fiber through different sizes of heckling combs or heckles. A heckle is like a bed of sharp, polished steel pins set into wooden blocks.

Images for kids

-

De vlasoogst (1904) ("The flax harvest") painting by Emile Claus, Royal Museums of Fine Arts of Belgium, Brussels, Belgium

-

A flax field in bloom in North Dakota, United States

See also

In Spanish: Lino para niños

In Spanish: Lino para niños