Burden Iron Works facts for kids

Quick facts for kids |

|

|

Burden Iron Works Site

|

|

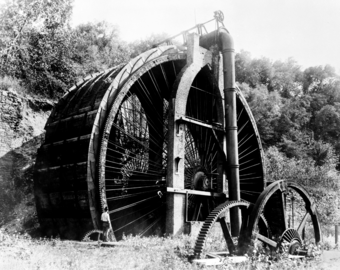

Waterwheel at Burden Iron Works, Troy, NY

|

|

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

| Nearest city | Troy, New York |

|---|---|

| Area | 50 acres (20 ha) |

| Built | 1813 |

| Architect | Burden, Henry |

| NRHP reference No. | 77000977 |

| Added to NRHP | November 10, 1977 |

The Burden Iron Works was a huge factory complex. It was located on the Hudson River in Troy, New York. This site was once home to the amazing Burden Water Wheel. This wheel was the most powerful vertical water wheel ever built!

Many people believe that George Washington Gale Ferris Jr. saw this wheel. He later invented the famous Ferris wheel. The old iron works site is now a protected archaeological site. It was added to the National Register of Historic Places in 1977. The main office building was listed even earlier, in 1972.

Contents

Who Was Henry Burden?

Henry Burden was born in Scotland on April 22, 1791. His father was a farmer. Henry studied engineering at the University of Edinburgh. He then moved to America in 1819.

Henry started working at a foundry in Albany, New York. They made things like cast iron plows. The very next year, he invented a better plow. He also created a new type of cultivator. People said it was the first practical one in America. He also improved machines for threshing grain and grinding flour.

Moving to Troy

In 1822, Henry moved to Troy. He became the superintendent of the Troy Iron and Nail Factory. This factory was near the Wynantskill Creek. Henry's inventions made the factory much more efficient. His machines did work that people used to do by hand.

The factory became very successful and profitable. Henry soon owned the entire factory. He renamed it H. Burden and Sons. This company became known as the Burden Iron Works. They made many different products from iron.

What Was the Iron Works Like?

Henry Burden knew that Troy was a great location. It had good connections for water transportation and railroads. This made it easy to make and ship many goods. Burden replaced the small wooden mill with a much larger one.

The river next to the factory was shallow. It also had many sandbars. The land often flooded. Henry spent a lot of money to fix this. He had the land filled in and the river dredged. This allowed large ships to reach the company's docks. The property had almost a mile of riverfront. The Hudson River Railroad ran right by it.

The Mighty Burden Water Wheel

To power his huge factory, Henry needed a lot of energy. In 1851, he designed and built a giant water wheel. This wheel was 60 feet tall! It might not have been the tallest, but it was likely the most powerful.

The Burden Water Wheel was 62 feet across. It was also 22 feet wide. A small stream, the Wynantskill Creek, supplied its water. Henry created a system of reservoirs along the creek. These held water in reserve for the mills.

The wheel weighed 250 tons. It could produce 500 horsepower. It spun about 2.5 times every minute. This amazing wheel was made mostly of iron. It worked day and night for almost 50 years! People called it 'the Niagara of Water-wheels'.

Busy Factories and Products

The Burden Iron Works had two main parts. The 'upper works' used water power from the Wynantskill. The 'lower works' used steam power.

The Upper Works had a rolling mill and a forge. It also had a horseshoe factory. There was a huge warehouse for 7,000 tons of horseshoes. Other buildings included a rivet factory and offices.

The Lower Works had two massive blast furnaces. These were 65 feet tall. There were also casting houses and stock houses. Other buildings included a machine shop, a blacksmith shop, and a foundry. Coal dust and smoke often covered this area of Troy.

Together, the two sites had many machines. There were 60 puddling furnaces and 20 heating furnaces. They had 14 rolling machines and 9 horseshoe machines. There were also 12 rivet machines. Each rivet machine could make 80 rivets a minute!

Hundreds of men worked at the puddling furnaces. It was very hot and dusty work. Boys also worked at the swaging furnaces. They used tongs to move hot horseshoes. Burden's factory made many types and sizes of horseshoes. They were packed in kegs weighing 100 pounds.

Moving Materials and Goods

A network of railroad tracks moved materials around the factory. Trains carried iron ore and sand to the furnaces. The company even owned its own locomotive.

Henry's son, William, designed steam derricks. These machines unloaded coal. A wire cable stretched 300 feet from the dock to the coal pile. An iron carriage moved along the cable. It carried a self-dumping bucket that held a ton of coal. A steam engine lifted the bucket. Then it traveled along the cable and dumped its load.

Huge piles of iron ore were next to the coal. This ore mostly came from the Lake Champlain area. There were also piles of limestone. Limestone, from Hudson, New York, helped melt the ores.

The company owned 50 horses and many wagons. These moved ore, coal, sand, and finished goods. They also owned iron mines with high-quality ore. And they had limestone quarries for the furnaces.

Burden Iron Works Today

Today, the old office building of the Burden Iron Works is a museum. This beautiful brick building was built in 1881-1882. It shows off the industrial history of Troy. You can see examples of things made in the city during the 1800s.

The Hudson Mohawk Industrial Gateway runs the museum. It is open by appointment only.