Cam (mechanism) facts for kids

A cam is a special part in a machine that helps change one type of movement into another. Imagine a spinning wheel or shaft that isn't perfectly round. As it spins, it pushes against another part, called a follower. This pushing action makes the follower move in a straight line, often back and forth.

Think of it like this: a cam takes a spinning motion and turns it into a pushing and pulling motion. A simple example is a bumpy disc that, as it turns, makes a lever go up and down. Cams were once very common in things like washing machines to control how they worked, before computers took over.

Contents

What is a Camshaft?

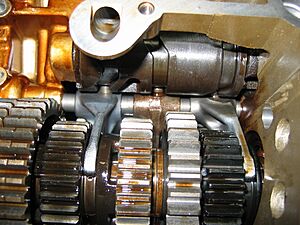

A camshaft is a long rod with several cams attached to it. It's a key part that turns spinning motion into a back-and-forth movement.

Camshafts in Car Engines

A great example is the camshaft in a car engine. The engine spins the camshaft. As the cams on the shaft rotate, they push open and close the valves in the engine's cylinders. These valves let air and fuel into the engine and let exhaust gases out. Without cams, a car engine wouldn't be able to breathe!

How Cams Move Things: Displacement Diagrams

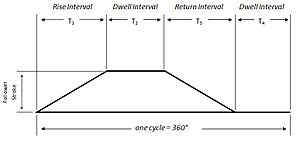

We can understand how a cam works by looking at its "displacement diagram." This is like a map that shows exactly where the follower will be at every point as the cam spins.

Imagine the cam spinning in a circle. The diagram shows how far the follower moves away from the cam's center at each angle of rotation.

A simple diagram might show the follower moving up at a steady speed, then staying still for a bit, and then moving back down.

- Rise: When the follower moves away from the cam.

- Dwell: When the follower stays still.

- Return: When the follower moves back towards the cam.

Types of Cams

Disc or Plate Cams

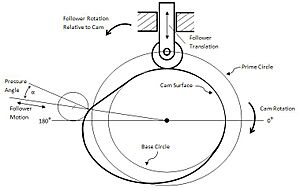

The most common type of cam is the disc cam, also called a plate cam or radial cam. It's usually a flat piece of metal cut into a special shape.

With a disc cam, the follower moves in a flat plane, straight up and down or side to side, as the cam spins.

- The base circle is the smallest circle you can draw around the cam's shape.

- The pitch curve shows the path the center of the follower would take as the cam rotates.

Disc cams were used in older machines, like automatic tools, to control different movements. They are also found in some home appliances, like dishwashers and washing machines, to control switches and different cycles.

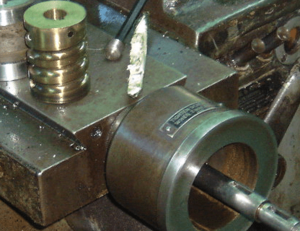

Cylindrical or Barrel Cams

A cylindrical cam (or barrel cam) is shaped like a cylinder. The follower rides in a groove cut into the surface of the cylinder.

These cams are great for changing spinning motion into straight-line motion that goes across the cylinder. A cylindrical cam can have many grooves and move several followers at once. They can also make the follower move for more than one full spin of the cylinder.

You can find cylindrical cams in:

- Machine tools, like saws that move back and forth.

- Gear shifters in motorcycles, where they help you change gears smoothly.

A special type is a constant lead cylindrical cam. Here, the follower moves at a steady speed as the cylinder spins, much like a screw thread.

Face Cams

A face cam works by having a follower ride on the flat face of a disc. Often, the follower moves in a slot cut into the disc's face. This slot guides the follower precisely, so it doesn't need a spring to keep it in contact with the cam.

Face cams can create repeated movements if the groove forms a closed loop. They can also be used to create specific patterns of movement.

A common example of a face cam is the lock on an old-fashioned sash window. The cam is on the bottom window, and a hook on the top window acts as the follower. When you turn the cam, it pushes the hook, locking the window tightly.

Heart-Shaped Cams

As the name suggests, this cam is shaped like a heart. It's used to bring a shaft back to a specific starting position. For example, they were used in old Post Office clocks to make sure the clock's time matched Greenwich Mean Time exactly.

Snail Drop Cams

This cam looks a bit like a snail shell. It was used in old timekeeping clocks, like "clocking-in" machines, to make sure the day changed over at exactly midnight. The cam would slowly lift a weight over 24 hours. At midnight, the cam's shape would suddenly drop the weight, which would then trigger the day to advance. This design made sure the timing was very accurate.

Linear Cams

A linear cam is different because the cam itself moves in a straight line, not in a circle. The cam can be a flat plate or a block. The key idea is that the input motion is straight, not spinning. The cam's shape can be cut into its edges or as grooves on its surface.

A great example of a linear cam is a key for a pin tumbler lock. When you put a key into a lock, the bumps and cuts on the key act as a linear cam. They push the tiny pins (the followers) inside the lock to the correct height, allowing the lock to open. When a key is copied, the original key acts as a linear cam to guide the machine that cuts the new key.

History of Cams

Cams are very old! The first cam-like parts appeared in China around 600 BC. These were in crossbow triggers. Later, around 206 BC to 8 AD, cams were used in China in water-powered machines, like hammers that pounded grain.

In ancient Greece, cams were part of amazing water-powered robots in the 3rd century BC. Later, in the 1200s, a brilliant inventor named Al-Jazari used cams in his own clever machines. Cams then started appearing in European machines from the 1300s onwards.

In 1956, Waldo J Kelleigh in the United States patented an adjustable cam, showing how these simple but powerful devices continued to be improved and used in new ways.

See also

- Reciprocating motion

- Cam engine

- Swashplate

- Crank (mechanism)

- Eccentric (mechanism)

| George Robert Carruthers |

| Patricia Bath |

| Jan Ernst Matzeliger |

| Alexander Miles |