Computer-aided technologies facts for kids

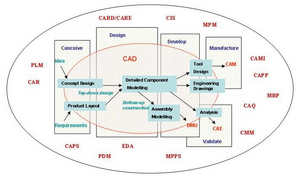

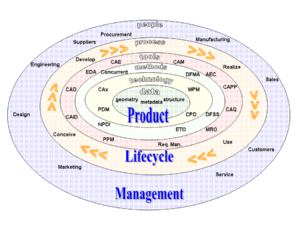

Computer-aided technologies (often called CAx) are special computer programs that help people design, test, and make products. Think of them as digital tools that make creating things much easier and faster. These technologies are used in almost every industry today, from making cars and airplanes to designing buildings and even toys.

Contents

What are Computer-Aided Technologies?

CAx tools use computers to help with many steps of creating a product. This includes the first idea, drawing the design, testing how strong it is, and even controlling the machines that build it. These tools help engineers and designers work more accurately and efficiently. They can also try out many ideas quickly without building physical models.

Designing with CAD

Computer-aided design (CAD) is like a super-powered digital drawing board. Instead of drawing with pencils, designers use CAD software to create detailed 2D drawings or 3D models of products. This could be anything from a new smartphone to a part for a rocket.

- CAD lets designers see their ideas in 3D.

- They can easily change designs and fix mistakes.

- It helps them make sure all parts fit together perfectly.

- CAD models can be shared easily with others.

Testing with CAE

Computer-aided engineering (CAE) tools help engineers test their designs on the computer. Before building a real product, CAE can show if it will be strong enough, how it will react to heat, or how air will flow around it.

- One common CAE tool is Finite Element Analysis (FEA).

- FEA breaks a design into tiny pieces.

- It then calculates how each piece will behave under stress.

- This helps find weak spots before anything is built.

- CAE saves a lot of time and money by preventing problems early.

Making Things with CAM

Computer-aided manufacturing (CAM) is the link between the design and the actual making of a product. CAM software takes the 3D models from CAD and turns them into instructions for machines. These machines, like Computer Numerical Controlled (CNC) machines, can then cut, shape, or print the product automatically.

- CAM tells machines exactly what to do.

- It ensures products are made precisely as designed.

- CAM makes manufacturing faster and more accurate.

- It helps create complex shapes that would be hard to make by hand.

The Product's Journey: PLM

Product lifecycle management (PLM) is a way to manage a product from its very first idea to the end of its life. CAx tools are a big part of PLM. They help keep track of all the design files, tests, and manufacturing plans.

- PLM helps teams work together smoothly.

- It stores all product information in one place.

- This makes it easier to update designs or fix issues.

- PLM ensures everyone uses the latest information.

How CAx Helps Us

CAx technologies have changed how almost everything is made. They allow companies to:

- Create new products faster than ever before.

- Make products that are safer and more reliable.

- Reduce waste and save resources during manufacturing.

- Design very complex items, like microchips or advanced aircraft.

These tools are always improving. They help engineers and designers turn their ideas into real products that we use every day.

See also

In Spanish: Tecnologías asistidas por computadora para niños

In Spanish: Tecnologías asistidas por computadora para niños

| Jessica Watkins |

| Robert Henry Lawrence Jr. |

| Mae Jemison |

| Sian Proctor |

| Guion Bluford |