Gas-checks in British RML heavy guns facts for kids

Gas-checks were special parts added to ammunition for large, powerful guns called RML heavy guns. These guns started being used around 1865. At first, their bullets had small "studs" that helped them spin as they left the gun. But in 1878, gas-checks were invented. They made the guns last longer and shoot much farther and more accurately. Soon, new bullets were made without studs, using only gas-checks to make them spin. Gas-checks also helped create a new type of RML gun that used a different kind of barrel design.

Contents

What are Gas-Checks?

The first RML heavy guns used a barrel design called "Woolwich rifling." This design had a problem: hot gas from the gunpowder would escape around the bullet. This escaping gas, called "windage," wore down the inside of the gun barrel very quickly.

Scientists worked hard in the 1870s to fix this. By 1878, they had designed two types of gas-checks. Both were made of copper with a little zinc. They looked like shallow cups that fit onto the back of the bullet. When the gun fired, the gas pressure pushed the sides of the cup outwards. This sealed the barrel, stopping the gas from escaping.

They quickly found that gas-checks did more than just protect the barrel. They also made the bullets fly farther and hit targets more accurately. Plus, they realized gas-checks could make the bullet spin all by themselves! This meant bullets no longer needed studs. This led to a new barrel design called "polygroove rifling," which used many shallow grooves instead of a few deep ones. Polygroove rifling was better for the strength of the guns. Also, bullets without studs were stronger and flew even more accurately.

Attached Gas-Checks

Attached gas-checks were used with the older bullets that already had studs. Their design was similar for all gun sizes. The gas-check was screwed onto the back of the bullet. This meant older bullets had to be slightly changed to fit them. A few bullets couldn't be changed and were thrown away.

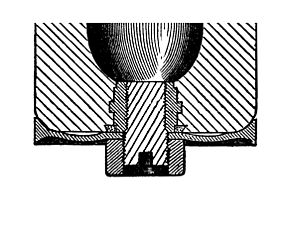

Figure 1 shows the back of a 9-inch "Palliser shell" (a type of armor-piercing bullet) with an attached gas-check Mk I. This gas-check was a wavy disc with a circular edge. When the gun fired, the gas pressure flattened the disc. This pushed the edge outwards into the barrel's grooves, creating a tight seal.

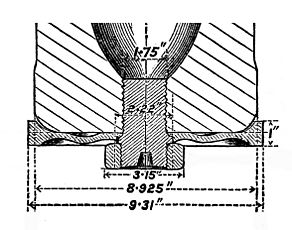

The Mk I gas-check worked well with fast-burning gunpowder. But with slower-burning powders, it sealed too slowly. This caused scratches inside the barrel. So, by 1881, the Mk I was replaced by the Mk II gas-check. Figure 2 shows a 9-inch "common shell" (a regular explosive bullet) with a Mk II gas-check. The Mk II was almost the same as the Mk I, but its edge had small bumps. These bumps fit into the barrel's grooves right away, making the seal happen much faster.

Automatic Gas-Checks

Automatic gas-checks were used with newer bullets that had no studs. They worked in both Woolwich and polygroove rifled guns. They were also called "Rotating Gas-Checks" or "EOC Gas-Checks."

They were called "automatic" because they could be loaded into the gun barrel separately from the bullet. Then, when the gun fired, they would automatically attach firmly to the bullet. They were called "rotating" because they made the bullet spin. "EOC" came from the Armstrong company, which developed them.

Automatic gas-checks were usually placed in the barrel first, then the bullet was loaded behind them. This way, the gas-check would sit on the back of the bullet, but not be attached yet. When the gun fired, it would become firmly attached and stay with the bullet all the way to the target. Sometimes, the gas-check could even be attached to the bullet before loading.

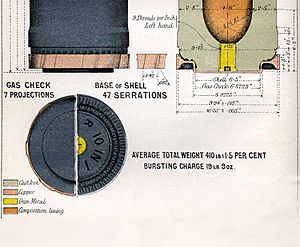

Figure 3 shows the back of a 10-inch "common shell" (Mk I) with an automatic gas-check. This is how it would look inside the gun before firing. The center of the bullet's back has a round, flat-topped bump with slanted sides. The outer part of the back has two circular grooves and many small ridges. The gas-check itself has seven bumps that fit into the barrel's grooves.

When the gun fires, the gas pressure pushes the copper gas-check into the slanted sides of the bump, the grooves, and between the ridges. This permanently attaches the gas-check to the bullet. The gas pressure also pushes the gas-check's edge outwards, sealing the barrel. The ridges on the bullet's back stop the gas-check from spinning on its own, forcing the entire bullet to spin.

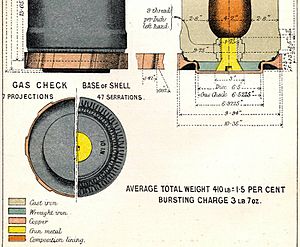

Figure 4 shows a 10-inch "Palliser shell" (Mk II) with an automatic gas-check. The gas-check is the same as in Figure 3. However, the bump on the back of this bullet is not part of the bullet itself. It's a separate iron disc attached by a screw.

At first, all studless bullets from 9 to 17.72 inches were made in one piece, like in Figure 3. These were called Mark I. But making Palliser shells (which were made of brittle metal) in one piece was very hard, especially for smaller sizes. Also, the bumps on these bullets could chip easily. So, later Palliser shells (9 to 12.5 inches) were made in two pieces, like in Figure 4. These were called Mark II. The separate bumps were made from stronger metals like wrought iron or cast steel.

Some Woolwich groove guns had two versions of automatic gas-checks. The changes to the Mark I mostly involved shaving off parts of the bumps. This made them bend more precisely and quickly into the Woolwich grooves, sealing them faster.

Generally, different versions of the same gun used the same studless bullets. Also, these studless bullets used the same automatic gas-check. However, 9-inch and 10-inch guns had some versions with Woolwich rifling and others with polygroove rifling. In these cases, there was one automatic gas-check for all Woolwich versions and a different one for all polygroove versions.

Summary of Gas-Check Use

This table shows how different RML heavy guns used gas-checks around 1902.

| Gun Model | Barrel Type | Bullet Types Used | |||

|---|---|---|---|---|---|

| Type | Grooves | Studded (No Gas-Check) | Studded (With Attached Gas-Check) | Studless (With Automatic Gas-Check) | |

| 17.72 inch | Polygroove | 28 | Yes | ||

| 16 inch | Polygroove | 33 | Yes | ||

| 12.5 inch | Woolwich | 9 | Yes | Yes | |

| 12 inch 35 ton | Woolwich | 9 | Yes | Yes | |

| 12 inch 25 ton | Woolwich | 9 | Yes | Yes | |

| 11 inch | Woolwich | 9 | Yes | Yes | |

| 10.4 inch 28 ton | Polygroove | 21 | Yes | ||

| 10 inch 18 ton Marks I & II | Woolwich | 7 | Yes | Yes | |

| 10 inch 12 ton Marks III & IV | Polygroove | 32 | Yes | ||

| 9 inch Marks I-V | Woolwich | 6 | Yes | Yes | |

| 9 inch Mark VI LS | Polygroove | 27 | Yes | ||

| 8 inch 9 ton gun | Woolwich | 4 | Yes | Yes | |

| 8 inch 70 cwt howitzer | Polygroove | 24 | Yes | ||

| 8 inch 46 cwt howitzer | Woolwich | 4 | Yes | Yes | |

| 7 inch 7 ton | Woolwich | 3 | Yes | ||

| 7 inch 6.5 ton | Woolwich | 3 | Yes | ||

| 7 inch 90 cwt | Woolwich | 3 | Yes | ||

- All guns with polygroove rifling (orange rows) only fired studless bullets with automatic gas-checks.

- Most guns with Woolwich rifling (blue rows), except 7-inch guns, fired both studded bullets (with attached gas-checks) and studless bullets (with automatic gas-checks).

- The 8-inch gun only fired one type of studless bullet.

- The 7-inch guns only fired studded bullets without gas-checks.

Timeline of Gas-Checks

- 1865-1878: The first RML heavy guns with Woolwich rifling were put into service. After this time, all new RML guns used polygroove rifling.

- 1879-1881: Most existing studded bullets (9 inches or larger) were changed to use an attached gas-check.

- 1879-1882: Making new studded bullets stopped for guns 9 inches or larger.

- 1880-1881: The attached gas-check Mk I was replaced by the Mk II, which had bumps to fit into the barrel grooves better.

- 1879-1884: Studless bullets became available for all guns 9 inches or larger.

- 1905: RML guns with Woolwich rifling were mostly outdated. Only 12.5, 10, and 9-inch guns were still considered useful in wartime.

Images for kids

Images 2-8 show different types of ammunition used by the RML 12.5-inch gun in 1885. This was typical for large Woolwich-grooved guns after the mid-1880s. These guns no longer fired studded bullets without gas-checks. Instead, they used either older studded bullets with attached gas-checks (Mk II) or newer studless bullets with automatic gas-checks. "Case shot" ammunition (Image 5) was different; it didn't have studs and didn't need gas-checks.

| Dorothy Vaughan |

| Charles Henry Turner |

| Hildrus Poindexter |

| Henry Cecil McBay |