Nottingham lace curtain machine facts for kids

The lace curtain machine is a special lace machine invented by John Livesey in Nottingham, England, in 1846. It was an improved version of an earlier machine called the bobbinet machine. This amazing invention helped create the many miles of lace curtains that were popular in homes during the Victorian era and beyond.

Contents

History of Lace Machines

The very first machine that led to mechanical lace-making was the stocking frame, invented in 1589. Imagine a weaving frame with special needles that moved back and forth. It made rows of loops, similar to knitting.

Over time, people made changes to this machine. In 1759, Jedediah Strutt updated it to make ribbed fabric. Then, in 1764, another inventor added a "tickler stick" to move loops sideways. This was an early step towards making lace with machines, but it still needed a lot of human help.

The Lace Curtain Machine Arrives

John Livesey invented the lace curtain machine in Nottingham in 1846. At first, people thought it was a type of Leavers machine, which made lace with a hexagonal (six-sided) pattern. However, Livesey's machine was special because it made a straight, square-shaped net.

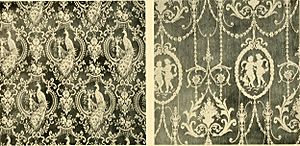

To create beautiful patterns on the lace, inventors used a system called Jacquard weaving. This system used special cards, like punch cards, to control the threads and make complex designs.

At the famous The Great Exhibition in 1851, people saw incredible lace curtains made by these machines. Some curtains were 5 yards (460 cm) long and 2 yards (180 cm) wide! Their detailed designs needed more than 12,000 Jacquard cards to create. The lace curtain industry grew very quickly because large, tall windows became fashionable in homes.

Over the years, these machines became much wider, some reaching 420 inches (11 m). By 1928, even a 300 inches (7.6 m) wide machine was considered small. However, around 1900, other types of lace, like Schiffli lace (which is embroidered onto a net), became popular. Later, in the 1950s, new machines like the Raschel and the use of artificial fibres also changed the lace industry.

How the Machine Works

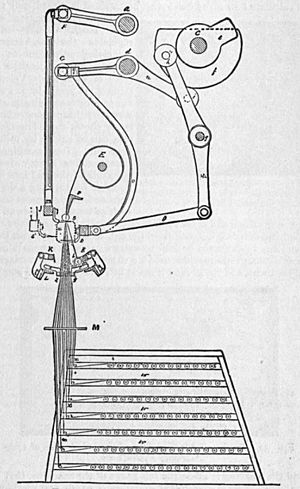

From the front, the lace curtain machine looks a lot like a Leavers machine. But it works differently because it creates a square net, not a hexagonal one. The Nottingham lace curtain machine uses only one main set of threads called the warp. The threads that make the patterns are held on spools, not on a large beam.

The machine uses terms like "rise," "fall," "right," "left," "sley," "carriage," and "comb" to describe its movements. The finished lace is collected at the top of the machine, unlike some other machines where it's collected at the bottom. A special roller called a "porcupine" helps keep the lace tight as it's collected.

The Curtain Machine's Threads

A lace curtain machine uses four main groups of threads to create the lace: the warp, top board, bottom board, and bobbin threads. For example, a large machine might have 3,600 threads in each group, making a total of 14,400 threads! The term 'point' tells you how many warp threads there are per inch.

- The warp threads run straight down the lace. They come from a large roll (the warp beam) at the bottom. They pass through a guide (called a sley) and then through the front guide bar. These threads create the basic structure, or "skeleton," of the fabric. They don't make patterns themselves.

- The top board threads can act as both the main threads (warp) and the crossing threads (weft). They can connect to the main structure or move sideways to create parts of the pattern. These threads pass through springs to keep them tight and then through the back guide bar.

- The bottom board threads (sometimes called a Swiss board) act as the crossing threads (weft) for both the main fabric and the patterns. These threads are usually finer. If the pattern is very detailed, these threads come from spools. If the pattern is simpler, they can come from a beam. They also pass through tension springs and a middle guide bar.

- The bobbin threads are very important because they tie all the other threads together. They are carried on small brass bobbins held in special carriers (carriages). These carriages swing back and forth, pushing and catching the threads. The bobbin threads secure the top and bottom board threads to the main warp threads. Patterns are made by making the spool threads (top or bottom board) move longer distances.

The machine has three guide bars, which are controlled by special cams. These cams allow the threads to move across 2, 3, or 4 "gaits" (small sections). The cams are always moving, but a Jacquard mechanism can stop certain threads in the middle and back bars. Each bobbin thread has a small steel wire (a jack) that can stop its movement. This creates holes in the pattern, making the lace look open and decorative.