Olive oil extraction facts for kids

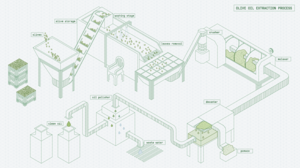

Olive oil extraction is how we get oil from olives! Olives are actually a type of fruit, and the oil is stored in tiny droplets inside their cells. This process is all about separating the oil from the rest of the olive fruit, like its water and solid parts.

The cool thing about olive oil is that it can be separated using only physical methods. This is because oil and water don't mix, making them easy to split apart. Other oils, like some vegetable oils, often need chemicals to be extracted.

The very first step in making olive oil is to wash the olives. This helps remove any dirt or other unwanted bits. If dirt stays on, it can give the oil a "soil taste," which isn't very nice!

Contents

How Olive Presses Work

People have been using olive presses for thousands of years, ever since the ancient Greeks started pressing olives over 5,000 years ago! An olive press works by squeezing olive paste really hard. This pressure pushes out the liquid, which is a mix of oil and water, leaving the solid parts behind. The oil and water then separate naturally because oil floats on top of water.

Traditional olive presses used to have a big, round millstone that would grind the olives and their pits into a paste. Animals often helped turn this stone. After grinding, the paste was collected and kneaded. Then, it was placed into special woven baskets called "frails." These baskets were stacked up, and a heavy stone weight was put on top to squeeze the oil out.

The liquid that came out was a mix of oil and olive water. This mix would flow into a pit. After a while, the oil would rise to the top and could be scooped off. Sometimes, the oil was filtered to make it even clearer. The leftover olive pulp was often used to light fires.

This old method is still used today and can produce excellent olive oil if done carefully.

First, olives are ground into a paste using large millstones. The paste usually stays under the stones for about 30 to 40 minutes. This time helps:

- Make sure the olives are fully ground.

- Allow tiny oil droplets to join together and form bigger ones.

- Let natural fruit enzymes create the oil's flavor and smell.

In modern mills, after grinding, the olive paste is spread onto special fiber discs. These discs are stacked up and put into a mechanical press. Today, these discs are made of synthetic fibers, which are easier to clean.

These stacks of discs are then placed under a powerful hydraulic piston. The piston applies a lot of pressure, squeezing the liquid (oil and water) out of the olive paste. The liquids are then separated, either by letting them settle or by using a fast spinning machine called a centrifuge.

To make sure the oil is high quality, it's important to clean the discs and grindstones properly after each use. If old paste is left behind, it can ferment and spoil the flavor of the next batch of oil.

Different Grades of Olive Oil

In ancient times, people used different methods to make various grades of olive oil.

- The best oil came from ripe olives picked from the very top of the tree. These were pressed lightly, producing a very sweet and thin oil.

- Other olives, with varying ripeness, were pressed with more weight to get more oil.

- Lower quality oil came from unripe olives that were stored for a long time until they became soft or shriveled before grinding.

Benefits and Drawbacks

Cleaning the equipment properly leads to better quality oil. Using grindstones is a good way to crush olives because it breaks up the fruit's pulp without damaging the pit or skin too much. This helps prevent the release of enzymes that can make the oil go bad. Also, this method uses less water, which means more of the healthy compounds called polyphenols stay in the oil. The leftover paste, called pomace, is also drier and easier to handle.

Advantages of Traditional Pressing:

- Better grinding of olives, which helps keep the oil from spoiling.

- Less water added, so more healthy polyphenols remain.

- Drier leftover pomace, which is easier to manage.

Disadvantages of Traditional Pressing:

- Hard to clean the equipment thoroughly.

- The process is not continuous, meaning there are waiting times. This exposes the olive paste to air and light, which can affect quality.

- Requires more people to do the work.

- Takes longer to produce the oil from harvest to pressing.

Modern Centrifuge Method

The modern way to extract olive oil uses a large industrial machine called a decanter centrifuge. In this method, olives are crushed into a very fine paste using machines like hammer crushers. This paste is then gently mixed for 30 to 60 minutes. This mixing helps the tiny oil droplets come together to form bigger ones. The flavors of the oil also develop during these steps thanks to fruit enzymes.

After mixing, the paste is pumped into the decanter. Water is often added to help the extraction process.

The decanter is a huge horizontal spinning machine that rotates very fast, about 3,000 times a minute! This high speed separates the different parts of the olive paste based on their weight: solids, olive water, and oil. Inside the decanter, a special coil pushes the solid parts out.

The separated oil and olive water are then put through another spinning machine, a vertical centrifuge, which spins even faster (around 6,000 times a minute). This machine separates any tiny bits of olive water still in the oil, and vice versa.

Types of Decanters

- Three-phase decanters: These use more water, which can wash away some of the healthy polyphenols from the oil. They also produce a lot of olive water that needs to be handled.

- Two-phase decanters: These use less water, which helps keep more polyphenols in the oil. They separate the olive paste into just two parts: oil and a wetter pomace (leftover solids). This wetter pomace can be harder to process later.

- Two-and-a-half-phase decanters: These are a mix of the two. They separate the paste into three parts but use less added water and produce less olive water than the three-phase type. This makes the pomace easier to handle.

Modern decanters can extract a lot of oil, usually between 85% and 90% in the first go. With a second extraction, the yield can go up to 96%!

Benefits and Drawbacks of Centrifugation

Advantages:

- Machines are compact and take up less space.

- The process is continuous and automated, meaning it runs by itself.

- Less manual labor is needed.

- Extracts the highest percentage of oil.

- Olive oil from two-phase systems can have more healthy compounds and resist spoiling better.

Disadvantages:

- Machines can be expensive.

- Requires skilled workers to operate.

- Uses a lot of energy.

- The leftover pomace can be moist and harder to deal with.

- More olive water might need to be disposed of.

- Adding water can reduce the amount of healthy antioxidants in the oil.

- Machines can wear down from rocks or grit in the olives.

Sinolea Method

The Sinolea method, introduced in 1972, is a different way to get oil from olives. In this process, many metal discs or plates are dipped into the olive paste. The oil naturally sticks to the metal plates. Then, scrapers remove the oil in a continuous flow. This method works because oil and olive water have different surface tensions, meaning oil prefers to stick to the steel plates.

The Sinolea process isn't completely efficient, as it leaves a good amount of oil in the paste. So, the remaining paste usually has to be processed again using the standard modern decanter method to get all the oil out.

Benefits and Drawbacks of Sinolea

Advantages:

- The oil has a higher content of healthy polyphenols.

- It's a low-temperature method, which helps preserve oil quality.

- It's automated and requires little manual labor.

- The oil and water separation step isn't needed.

- Uses less energy.

Disadvantages:

- Often needs to be combined with another method to get all the oil, which means more space and work.

- Large metal surfaces can cause the olive product to spoil faster if not handled quickly.

- New Sinolea machines are currently not allowed to be sold in the European Union because it's hard to clean their large surfaces properly.

"First Cold Pressed" and "Cold Extraction"

You might see olive oils labeled "first cold pressed" or "cold extraction." This means no extra heat was added during the oil extraction process. "Pressed" simply means the olives were crushed in a mill to get the oil.

In the European Union, these labels mean that the temperature during mixing and extraction was kept below 27°C (80°F). If olive oil is bottled outside the EU, these rules might not apply, so you can't always be sure if the claims are true.

Keeping the temperature low during extraction is very important for olive oil quality. High temperatures can make the oil lose its delicate flavors and spoil faster. Also, the amount of healthy compounds like polyphenols, antioxidants, and vitamins in the oil can be reduced by higher temperatures. Producers often adjust the water temperature during processing to control this. Higher temperatures are sometimes used to get more oil from the paste, but this can affect quality.

Combining Methods

Some olive oil producers, especially smaller ones who focus on very high quality, combine old and new methods. They might use the traditional stone mill for grinding the olives, but then use a modern decanter for separating the oil. This way, they get the benefits of the stone mill (better grinding, less mixing time) without the hassle of cleaning the old press's fiber discs. However, because the stone mill process is not continuous (it stops and starts), it's usually not used for large-scale production.

What Consumers Should Know

You can get high-quality olive oil from any extraction method, as long as it's done correctly. The quality of the olives themselves and how quickly they are processed after harvesting are just as important as the extraction method.

The two main things that can spoil olive oil are oxygen and light. Once olives are picked, they should be pressed within 24 hours. Oxidation (when oil reacts with oxygen) starts right after harvesting. If olives wait too long, the oil inside them can start to break down, leading to lower quality oil with higher acidity.

Also, if too much oxygen mixes with the olive paste during extraction, the acidity can increase even more. Methods that keep oxygen and light away from the oil are best.

After extraction, most unfiltered olive oil looks a bit cloudy. This is because it still has tiny bits of water and olive pulp. This cloudy oil is often stored in cool, oxygen-free tanks with a sloped bottom. This allows the remaining solids and water to settle, making the oil clearer and helping it stay fresh longer.

The Future of Olive Oil Extraction

The future of olive oil extraction aims to make the process even better and reduce any negative effects on the oil. This includes:

- Reducing oxidation by doing some mixing and extraction in a nitrogen atmosphere (which has no oxygen).

- Removing the olive pits before grinding. This would reduce the release of enzymes that cause oxidation and create a pomace that can be used for animal feed.

- Using less added water to keep more healthy polyphenols in the oil.

- Improving the Sinolea method to make it more efficient, so less oil is left behind in the paste.