Punching facts for kids

Punching is a way to make holes in flat materials like metal sheets, paper, or plastic. It uses a special machine called a punch press and a tool called a punch. The punch pushes through the material to create a hole. This happens by a process called shearing, which means cutting the material cleanly.

Often, the punch pushes the material into a die, which is a shaped block on the other side. When the hole is made, a small piece of scrap material, called a "slug," is left behind. This slug falls into the die. Depending on the material, the slug might be recycled or thrown away. Punching is usually the cheapest way to make many holes in sheet materials. If a special punch is used to cut out many useful parts from a sheet, it's called blanking. Sometimes, metal is punched when it's hot, which is called hot punching.

Contents

How Punching Works

The tools used for punching, the punch and the die, are often made from strong metals like hardened steel or tungsten carbide. The die sits under the material and supports it around where the hole will be. This helps make a clean cut. There's a tiny gap between the punch and the die. This gap stops the punch from getting stuck and means less force is needed to make the hole. The size of this gap depends on how thick the material is. Thicker materials need a slightly bigger gap, but it's always smaller than the material's thickness.

The punch press pushes the punch through the material. This creates a hole that is about the same size as the punch. When the punch is removed, the hole might be a tiny bit smaller. Materials that can stretch a lot might stick to the punch. When this happens, the punch has to be pulled back out of the hole while the material is held still. This process is called stripping. The inside walls of the hole will look a bit shiny and might have some rough edges. The slug that was cut out falls through the die and is collected.

What's Special About Punching

Here are some cool things about punching:

- It's usually the cheapest way to make holes in metal sheets, especially when you need to make a lot of them.

- You can make holes in many different shapes, not just circles.

- The punches and dies are made from very strong metals.

- The sides of the hole will have a shiny area and some rough parts.

- It's a very fast way to make holes.

Different Shapes and Sizes

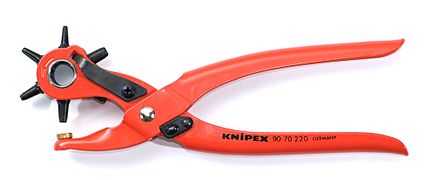

The material you punch is often a flat sheet or a roll. You can punch many different materials, like metals and plastics. The punch and die can be made in all sorts of shapes to create different kinds of holes. Sometimes, several punches are used at once to make a complex part in one go.

Usually, the punch and die are almost the same size. This creates a clean, cut edge when they meet. But if the punch is much smaller than the die, it can make an extruded hole. In this case, the punch pushes the material to the sides, forming a tube that sticks out from the sheet.

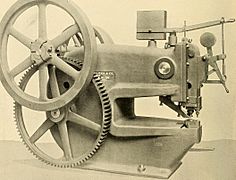

Punching Machines

Most punching machines are powered by motors, but some simple ones are hand-powered. A mechanical punch press has several main parts: a strong frame, a motor, a ram (which holds the punch), die posts, a bolster, and a bed (where the die sits). The punch is attached to the ram, and the die is attached to the bolster plate. After a hole is made, the scrap slug falls away, and the material moves forward for the next hole.

In factories, large computer-controlled punching machines are common. These are called CNC (Computer Numerical Control) punch presses. They often come in two types: 'turret' or 'rail'. A turret punch press has punches and dies on a spinning part called a turret. A rail type punch stores its tools on a rail at the back. These machines use strong hydraulic (liquid pressure) or pneumatic (air pressure) power to push the punch with enough force to cut through metal.

Punching Force

The amount of force needed to punch through a piece of metal depends on a few things. It depends on how thick the metal is, the total length of the cut (the perimeter of the hole shape), and how strong the material is.

The shape of the punch and die also changes the force needed. If the punch is flat, the force needed is very high all at once. A punch with a sloped or beveled edge helps to cut thicker materials by spreading out the force over the punching process. This means less force is needed at the very beginning of the cut. However, a bevelled punch can sometimes slightly change the shape of the hole.

Special dies, like compound dies, can do several shaping steps at once. But these can be slower and more expensive. Progressive dies are used for making many parts quickly. Different punching steps can happen one after another on the same machine.

Other Similar Processes

Punching is related to many other ways of shaping materials. These include stamping (which shapes metal), blanking (cutting out a usable part), perforating (making many small holes), parting (cutting a sheet into pieces), drawing (stretching metal), notching (cutting a notch), lancing (making a cut without removing material), and bending (folding material).

Punching in Plastics

When we talk about punching in plastics, it usually means removing extra plastic from a finished item. For example, in making plastic bottles, punching tools are used to cut off extra plastic pieces, like "tails" or "flash" (leftover plastic from the molding process), or to make holes for handles.

Some machines trim the plastic containers right inside the machine. Other machines need separate equipment to do the trimming afterward. This extra equipment can include tools to remove tails, rotating or moving punch trimmers, and spin trimmers.

See also

In Spanish: Troquelación para niños

In Spanish: Troquelación para niños

- Knockout punch

| William Lucy |

| Charles Hayes |

| Cleveland Robinson |