Rolling (metalworking) facts for kids

Rolling is a cool way to shape metal! Imagine a giant rolling pin flattening dough. That's pretty much what rolling mills do with metal. They pass big pieces of metal through strong rollers. This makes the metal thinner, more even, and gives it special properties.

There are two main types of rolling, depending on the metal's temperature:

- Hot rolling: This happens when the metal is super hot, above its "recrystallization temperature." Think of it as being so hot that its tiny parts (grains) can easily rearrange themselves. This prevents the metal from getting too hard.

- Cold rolling: This happens when the metal is cooler, below its recrystallization temperature, usually at room temperature. This makes the metal stronger and gives it a smoother finish.

Rolling is a huge part of manufacturing. Hot rolling shapes more metal than any other process! Rolling mills often turn metal, especially steel, into useful things like beams for buildings, bars, and rails for trains. Most steel factories have rolling sections that turn raw metal into finished products.

There are many ways to roll metal, like ring rolling, roll bending, and roll forming.

Contents

The History of Metal Rolling

People have been rolling metal for a very long time! Early versions of rolling mills were used in the Middle East and South Asia around 600 BCE. In Europe, some drawings by Leonardo da Vinci show ideas for rolling mills.

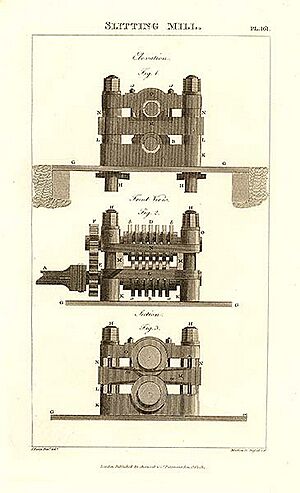

The first rolling mills in Europe were "slitting mills." They arrived in England from Belgium in 1590. These mills would flatten iron bars into plates. Then, other rollers with grooves would cut these plates into iron rods. Around 1670, people started experimenting with rolling iron to make tinplate.

In 1697, Major John Hanbury built a mill to roll "Pontypool plates." These were black iron plates that were later rolled again and coated with tin to make tinplate. Before this, iron plates were usually made by hammering them in forges.

The slitting mill was also used to make hoops for barrels and iron with special shapes.

A Swedish engineer named Christopher Polhem wrote about rolling mills in 1761. He explained how they could save a lot of time and effort. A rolling mill could make 10 to 20 or more bars at once!

In 1759, Thomas Blockley in England got a patent for polishing and rolling metals. Then, in 1766, Richard Ford, also from England, got a patent for the first "tandem mill." A tandem mill rolls metal through several sets of rollers one after another. Ford's mill was used for hot rolling wire rods.

Rolling Other Metals

Rolling mills for lead existed by the late 1600s. By the late 1700s, copper and brass were also being rolled.

Modern Rolling Techniques

For a long time, rolling mills got their power from water wheels. But in 1786, John Wilkinson used a steam engine to power a rolling mill. This was a big step! Steam engines made mills much more productive. Later, around 1900, electric motors took over from steam engines.

Modern rolling methods owe a lot to Henry Cort in England. In 1783, he got a patent for using grooved rollers to shape iron bars. With his new design, mills could make 15 times more metal per day than before! Even though he wasn't the very first to use grooved rolls, he combined many good ideas. That's why he's called the "father of modern rolling."

The first mill to roll train rails was set up by John Birkenshaw in England in 1820. He made long, strong iron rails. As technology improved, rolling mills and the products they made grew much larger. For example, at an exhibition in London in 1851, a huge iron plate, 20 feet long and weighing over 1,100 pounds, was shown!

Even more progress came in 1853 with the invention of "three-high mills." These mills used three rollers and were great for rolling heavy metal sections.

Hot Rolling vs. Cold Rolling

Hot Rolling Metal

Hot rolling happens when metal is heated above its "recrystallization temperature." This means the metal's internal structure can easily change and reshape. This process prevents the metal from becoming too hard.

The metal usually starts as large pieces, like ingots, slabs, blooms, or billets.

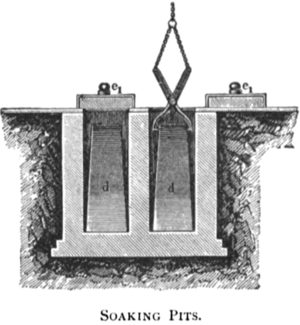

If these pieces come from a continuous casting process, they are already hot enough. If not, they are heated in large ovens called "soaking pits" or using "induction heating" for smaller pieces.

Workers must watch the metal's temperature carefully. It needs to stay hot enough to keep rolling easily. There's a "finishing temperature" that's a bit higher than the recrystallization temperature. If the metal cools too much, it has to be reheated before more rolling.

Hot-rolled metals usually have similar strength in all directions. They also don't have much "residual stress" (internal tension). However, sometimes tiny impurities can make them stronger in one direction. Also, thinner pieces might have some directional properties.

Uneven cooling can create a lot of residual stress, especially in oddly shaped pieces like I-beams. Hot-rolled products are good quality, but their surface has a dark layer called "mill scale." This is an oxide that forms from the heat. It's usually removed by cleaning processes like "pickling."

Hot-rolled steel is often cheaper than cold-rolled steel. It's mainly used to make flat sheets or simple shapes like train tracks.

Here are some common uses for hot-rolled metal:

- Truck frames

- Car parts like clutch plates and wheels

- Pipes and tubes

- Water heaters

- Farm equipment

- Metal straps

- Parts made by stamping

- Compressor shells

- Metal buildings

- Train car parts

- Doors and shelves

- Metal discs

- Guard rails for roads

Designing Shapes for Rolling

Rolling mills are often set up in stages: roughing, intermediate, and finishing. When making shaped products, a round or square metal piece (called a billet) is stretched and shaped. The goal is to get the final product with a smaller size and specific shape.

Engineers try to reduce the number of times the metal needs to pass through the rollers. This is because each rolling machine is very expensive. One way to do this is with a "slit pass" or "split pass." This divides a metal bar into two or more smaller parts. This helps to reduce the thickness faster in each pass.

Another way to reduce passes is by using smart computer systems. These systems use Artificial Intelligence to design the best way to roll the metal.

Cold Rolling Metal

Cold rolling happens when the metal is below its recrystallization temperature, usually at room temperature. This process makes the metal up to 20% stronger! It also makes the surface much smoother and allows for very precise sizes.

Common cold-rolled products include sheets, strips, bars, and rods. These are usually smaller than hot-rolled products. Because the metal is stronger and the pieces are smaller, special mills with many rollers are used. Cold rolling can't reduce the metal's thickness as much as hot rolling in one go.

Cold-rolled sheets and strips come in different "hardnesses." "Full-hard" rolling reduces thickness by 50%. "Skin-rolling" is a very small reduction (0.5-1%). It makes the surface smooth and uniform. It also helps prevent certain defects from forming later.

Other shapes can be cold-rolled if they have a fairly even cross-section and are not too wide. Cold rolling shapes usually involves many steps to get the final form.

Blacksmiths often find cold-rolled steel easier to work with. It's smoother and more consistent. However, it costs more than hot-rolled steel.

Here are some common uses for cold-rolled steel:

- Metal furniture (desks, cabinets, chairs)

- Motorcycle exhaust pipes

- Computer parts

- Home appliances

- Shelving and lighting fixtures

- Hinges and tubing

- Steel drums and lawn mowers

- Electronic cabinets

- Water heaters

- Metal containers and fan blades

- Frying pans

- Building materials

Different Rolling Processes

Roll Bending

Roll bending takes flat metal plates or sheets and shapes them into cylinders.

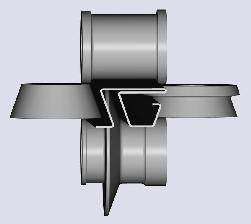

Roll Forming

Roll forming is a continuous process. A long strip of metal, often from a coil, passes through many sets of rollers. Each set of rollers bends the metal a little bit more. Eventually, the metal gets the desired shape. Roll forming is great for making very long parts or large amounts of parts.

There are different types of roll bending machines, like 4-roller, 3-roller, and 2-roller machines. Each has different benefits depending on the final product needed.

Flat Rolling

Flat rolling is the most common type of rolling. The metal starts as a rectangle and ends as a thinner rectangle. The metal goes between two rollers that spin in opposite directions. The space between the rollers is smaller than the metal's thickness, so it gets squeezed and stretched out.

Friction between the metal and the rollers pulls the metal through. If the metal is too thick for the gap, the rollers might just slip over it.

The final product is either a "sheet" (less than 6 mm thick) or a "plate" (thicker than 6 mm). Very thick plates are often made by pressing, which is called "forging," not rolling.

Sometimes, the rollers are heated to make the metal easier to work with. Lubrication is often used to stop the metal from sticking to the rollers. Adjusting the speed of the rollers and their temperature helps control the process.

For very thin metal sheets, like aluminum foil, a "cluster mill" is used. These mills have very small rollers. To make it easier, "pack rolling" is used. This is where multiple sheets are rolled together. As the foil sheets come out, they are trimmed and cut into smaller pieces. Aluminum foil is often made this way. You can tell because one side is shiny (from touching the roller) and the other side is dull (from touching another sheet of foil).

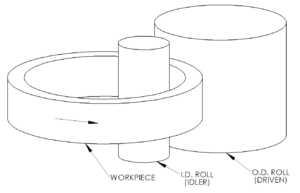

Ring Rolling

Ring rolling is a special hot rolling process that makes a metal ring bigger in diameter. It starts with a thick-walled ring. This ring is placed between two rollers: an inner "idler roll" and an outer "driven roll." The driven roll presses the ring from the outside. As the rolling happens, the ring's wall gets thinner, and its diameter gets larger.

The rollers can be shaped to create different cross-sections for the ring. This process makes the metal's internal structure go around the ring, which gives it better strength. Rings can be very large, up to 8 meters across!

Common uses for ring-rolled products include train wheels, bearings, gears, parts for rockets, turbines, airplanes, pipes, and pressure vessels.

Controlled Rolling

"Controlled rolling" combines shaping the metal with heat treatment. The heat used to roll the metal also helps to improve its properties. This means you don't need to do extra heat treatments later.

This process helps create a fine internal structure in the metal. It also controls how different parts of the metal (like ferrite or austenite in steel) are formed. This can make the metal stronger and tougher. To do this, the whole process must be carefully watched and controlled. Things like the metal's starting material, how much it's shaped, temperatures at different stages, and cooling conditions are all important.

The benefits of controlled rolling are better metal properties and saving energy.

Forge Rolling

Forge rolling is a process where heated metal bars are passed between two spinning roller segments. This reduces the metal's thickness in specific areas. It's mainly used to prepare metal for a later "die forging" process. By doing this, less material is wasted, the forces needed for forging are lower, and the final part has a better surface.

Most metals that can be forged can also be forge-rolled. It's often used to pre-shape long metal pieces for parts like crankshafts, connecting rods, and vehicle axles. Forge rolling usually doesn't make parts with super precise sizes. That's why it's mostly used for the first shaping steps, not the final ones.

Here are some good things about forge rolling:

- It's very productive and uses material well.

- The forge-rolled parts have a good surface.

- The tools last longer.

- The tools are smaller and cost less.

- The metal's internal structure is improved, making it stronger.

Rolling Mills: The Machines

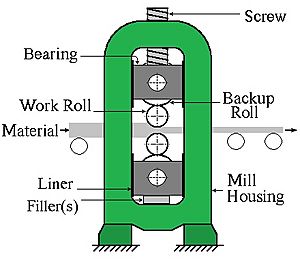

A "rolling mill" is the machine that does the rolling. It has several key parts:

- Work rolls: These are the main rollers that touch and shape the metal.

- Backup rolls: These are larger rollers behind the work rolls. They support the work rolls and stop them from bending under the pressure.

- Rolling balance system: This keeps the top rollers in the correct position.

- Roll changing devices: These are used to remove and put in new rollers.

- Mill protection devices: These stop too much force from damaging the rollers or the mill.

- Cooling and lubrication systems: These keep the rollers cool and help the metal move smoothly.

- Pinions: These are gears that split power to the two main rollers, making them spin at the same speed but in opposite directions.

- Gearing: This sets the desired speed for rolling.

- Drive motors: These powerful motors provide the energy for rolling.

- Electrical controls: These manage the power to the motors.

- Coilers and uncoilers: These unroll and roll up coils of metal.

Large pieces of metal called "slabs" are fed into hot strip mills or plate mills. "Blooms" are rolled into "billets" in a billet mill. The metal from a strip mill is coiled up and can then be used in a cold rolling mill or by other factories. Billets are rolled into various shapes like angles, channels, beams, and rods.

Mill Setups

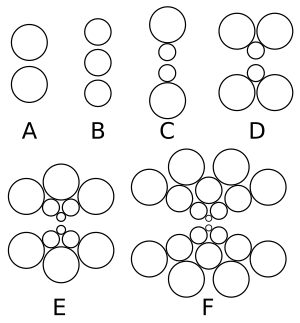

Rolling mills come in different designs. The simplest is a "two-high non-reversing" mill. It has two rollers that only spin in one direction. A "two-high reversing" mill has rollers that can spin both ways, but they have to stop and reverse for each pass.

To avoid stopping, the "three-high" mill was invented. It has three rollers that spin in one direction. The metal goes through one pair of rollers, then is lifted and sent back through the other pair. These mills are usually used for the first stages of rolling.

To use smaller rollers, a "four-high" or "cluster" mill is used. Smaller rollers are good because less of the roller touches the metal. This means less force and power are needed. But small rollers aren't as stiff. So, "backup rolls" are used to support them. A four-high mill has two small work rolls and two large backup rolls. A cluster mill has even more rollers, often in three layers. These mills are common for hot rolling wide plates, most cold rolling, and rolling thin foils.

Historically, mills were named after the products they made:

- Blooming, cogging, and slabbing mills: These were the first mills that prepared metal for rails, shapes, or plates.

- Billet mills: These reduced blooms into smaller billets.

- Beam mills: Made heavy beams and channels.

- Rail mills: Made train rails.

- Shape mills: Made smaller beams, channels, and other shapes.

- Merchant bar mills: Made various bar shapes.

- Rod and wire mills: Made rods and wire.

- Plate mills: Made metal plates.

- Sheet mills: Made thin metal sheets.

- Universal mills: Used vertical and horizontal rollers to make square-edged plates and wide shapes.

Tandem Mills

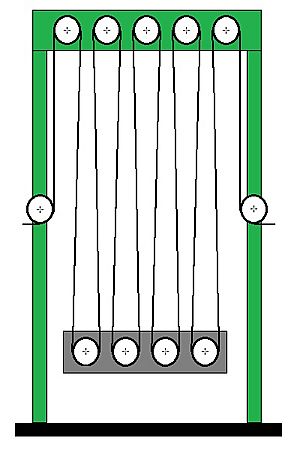

A tandem mill is a modern type of rolling mill where the metal is rolled in one continuous pass. Instead of several passes in one machine, a tandem mill has many "stands" (sets of rollers) in a row. The metal goes through each stand one after another, getting thinner each time. Tandem mills can have anywhere from 2 to 18 stands.

Tandem mills can be used for both hot and cold rolling. Cold rolling tandem mills can be continuous or process metal in batches.

A continuous mill has a "looping tower." This tower holds extra metal strip, allowing the mill to keep rolling slowly. This happens while a welder joins the end of one coil to the start of the next. At the end of the mill, a special shear cuts the strip, and two coilers take turns winding up the finished metal.

Looping towers are also used in other continuous processes, like annealing (softening metal with heat) and coating lines.

Problems That Can Happen During Rolling

Changes in Thickness Along the Length

In hot rolling, if the metal isn't heated evenly, some parts will flow more easily than others. This can lead to uneven thickness. If the temperature difference is too big, the metal can even crack. Cooler spots can happen because of how the metal rests on supports in the heating furnace.

In cold rolling, most thickness changes come from the backup rolls not being perfectly round. These tiny imperfections can cause the thickness to vary.

Engineers use special systems with hydraulic pistons to fix this. They measure the imperfections of the backup rolls. Then, the pistons adjust the rollers to cancel out these imperfections, making the metal thickness more even.

Flatness and Shape Issues

When a flat metal piece is rolled, it might not stay perfectly flat. This happens because the rollers squeeze the metal unevenly across its width. This creates internal stress. "Flatness" describes how much the metal bends or waves away from a perfectly flat surface.

For metal strips and sheets, flatness is about how much the metal stretches differently across its width. This needs to be carefully controlled so the metal can be used in other machines later.

Profile

"Profile" refers to the thickness across the width of the metal.

- Crown: This is how much thicker the center of the metal is compared to its edges.

- Wedge: This is how much thicker one edge is compared to the other.

It's usually good to have a little bit of crown. This helps the metal stay centered in the mill as it's being rolled.

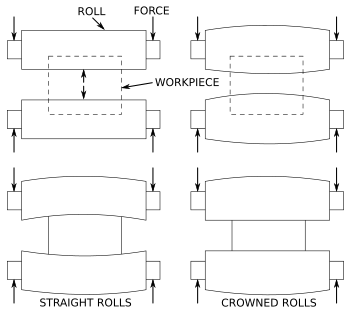

Flatness

It's hard to keep a perfectly even gap between the rollers. The rollers can bend under the heavy pressure needed to shape the metal. This bending makes the metal thinner at the edges and thicker in the middle.

One way to fix this is to use "crowned rollers" (rollers with a slight curve). But these only work perfectly for one specific set of conditions.

Other ways to fix roller bending include:

- Continual Varying Crown (CVC): This involves grinding a special curve into the rollers and then shifting them sideways. This allows the curve to be adjusted dynamically.

- Pair cross rolling: This involves tilting the ends of the rollers at an angle. This changes the gap at the edges, allowing for dynamic control of the crown.

- Work roll bending: Hydraulic cylinders push on the ends of the rollers to counteract bending.

Another way to reduce bending is to lower the force on the rollers. This can be done by pulling the metal as it's being rolled. Also, using stronger roller materials or adding more backup supports helps.

Flatness problems can happen even if the metal has the same thickness across its width. To make flat metal, it needs to be reduced by the same percentage across its entire width. This is important because if the metal stretches evenly across its width, it will stay flat.

Here are some types of flatness defects:

- Symmetrical edge wave: Both edges of the metal look "wavy" because the metal at the edges became longer than the metal in the middle.

- Asymmetrical edge wave: Only one edge is "wavy" because the metal on one side became longer than the other.

- Center buckle: The middle of the metal strip is "wavy" because the metal in the center became longer than the edges.

- Quarter buckle: This is rare, where the metal stretches in the areas between the center and the edges. This often happens if too much bending force is used on the rollers.

Draught (Thickness Reduction)

"Draught" is the difference between the metal's starting thickness and its final thickness after rolling. If the starting thickness is `t_i` and the final thickness is `t_f`, then the draught `d` is: `d = t_i - t_f`

There's a maximum amount of thickness reduction you can get in one pass. This depends on the roller's radius and how much friction there is between the roller and the metal.

Surface Defects

Here are six types of surface problems that can happen:

- Lap: This happens when a folded part of the metal gets rolled in but doesn't fully weld. It looks like a seam on the surface.

- Mill-shearing: These look like feather-like laps.

- Rolled-in scale: This happens when "mill scale" (the oxide layer) gets pressed into the metal.

- Scabs: These are long patches of loose metal rolled into the surface.

- Seams: These are open, broken lines that run along the metal's length. They can be caused by scale or rough rollers.

- Slivers: These are noticeable breaks on the surface.

Fixing Surface Defects

Many surface defects can be removed from semi-finished rolled products before more rolling. This process is called "scarfing." In the past, people used chisels or grinders. Now, they use oxy-fuel torches (which melt and blow away the metal) or even lasers.

See also

In Spanish: Laminación para niños

In Spanish: Laminación para niños

- Bernard Lauth, who invented cold rolling for iron.

- John B. Tytus, who invented the first practical continuous rolling process for steel.

- Tadeusz Sendzimir, who developed revolutionary ways to process steel and metals.

- Electron beam texturing, used to make roller surfaces rough.

- Drawer slides roll forming machine

- Calender

- Roll bender

| Anna J. Cooper |

| Mary McLeod Bethune |

| Lillie Mae Bradford |