Work hardening facts for kids

Work hardening, also called strain hardening, is a cool way to make metals or plastics stronger. Imagine bending a paperclip over and over – it gets harder to bend and eventually breaks. That's a bit like work hardening!

It happens when you shape a metal or plastic by bending, stretching, or squeezing it when it's cold. "Cold" usually means at room temperature, not heated up. This process changes the material inside, making it tougher and more resistant to breaking.

Contents

What is Work Hardening?

Work hardening is when a material, like a metal or a type of plastic, becomes stronger and harder after you change its shape permanently. This shaping is done without heating the material to a very high temperature. Think about how a blacksmith hammers hot metal to shape it; work hardening is similar, but it's done when the metal is cold.

How Does it Work?

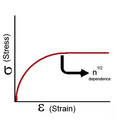

When you bend, stretch, or squeeze a metal, you are causing something called "plastic deformation." This means you are changing its shape in a way that it won't go back to its original form. Inside the metal, there are tiny structures called crystals. When you deform the metal, these crystals move and get tangled up. This tangling makes it harder for them to move again, which is why the metal becomes stronger and harder.

This process is usually done below the material's "recrystallization temperature." This is a special temperature where the metal's internal structure would start to rearrange itself and become softer again. By staying below this temperature, we make sure the strengthening effect lasts.

Common Ways to Work Harden Materials

There are several main ways to work harden materials, often called "cold-working operations." These methods are used to shape and strengthen metals for many different uses.

Rolling

Rolling is like using a giant rolling pin to flatten dough. Metals are passed between large rollers that squeeze them into thinner sheets or different shapes. This squeezing action makes the metal stronger. You can see rolled metal in things like car bodies or soda cans.

Bending

Bending is exactly what it sounds like! You take a flat piece of metal and bend it into a new shape, like making a metal bracket or a pipe. The parts of the metal that are stretched or compressed during the bend become harder.

Shearing

Shearing is like cutting with scissors, but for metal. A sharp blade pushes through the metal, cutting it into pieces. The edges where the metal is cut can become harder due to the force applied. This is used to cut metal sheets into specific sizes.

Drawing

Drawing involves pulling a metal through a smaller opening or die. Imagine pulling a thick piece of play-doh through a small hole to make a thin string. This process makes the metal longer and thinner, and also much stronger. This is how wires are made, from tiny electrical wires to thick cables.

Why is Work Hardening Important?

Work hardening is super important in making many things we use every day. It allows engineers to create parts that are strong, durable, and can withstand a lot of stress without breaking. For example, the strong frame of a bicycle, the tough body of an airplane, or the durable springs in a car all benefit from work hardening. It helps materials last longer and perform better in their jobs.

Images for kids

See also

In Spanish: Endurecimiento por deformación para niños

In Spanish: Endurecimiento por deformación para niños

| Kyle Baker |

| Joseph Yoakum |

| Laura Wheeler Waring |

| Henry Ossawa Tanner |