Boerenkaas facts for kids

Quick facts for kids Boerenkaas |

|

|---|---|

|

|

| Country of origin | Netherlands |

| Source of milk | Cows, buffalos, goats or sheep |

| Pasteurised | Possibly |

| Texture | Semi-hard |

| Weight | 1–2 kg |

| Certification | TSG |

Boerenkaas (which means farmers cheese in Dutch) is a special type of Dutch cheese. It is mostly made by hand on farms. Farmers use fresh, raw milk from cows, goats, sheep, or even buffalo to make it. Sometimes, they add tasty things like cumin seeds, other seeds, herbs, or spices to the cheese.

Boerenkaas is very unique. Its name has been officially protected by the European Union since 2007. This means that only cheese made in the Netherlands on a cheese farm, following very old and special methods, can be called Boerenkaas. It's like a special badge of honor for this traditional cheese!

Contents

How Boerenkaas is Made

Making Boerenkaas is a careful process that takes several steps. It starts with fresh, raw milk directly from the farm animals.

Getting Started with Milk

First, the fresh, raw milk is warmed up to about 29 degrees Celsius (which is around 84 degrees Fahrenheit). Then, something called rennet is added. Rennet is a natural ingredient that helps the milk thicken and separate.

From Milk to Curd

After about 30 minutes, the milk turns into a soft, jelly-like substance called curd. The cheesemakers then cut this curd into tiny pieces, about the size of a pea. As they cut, a yellowish liquid called whey separates from the curd. Part of this whey is removed.

Washing the Curd

Next, hot water is added to the curd.

- For cow's milk, hot water is added twice. First, the curd is heated to 33 degrees Celsius (91°F). About 15 minutes later, it's heated again to 36 degrees Celsius (97°F).

- For goat's milk, it's usually heated to 36 degrees Celsius (97°F) all at once.

After adding the hot water, the cheesemakers stir the curd very slowly for about half an hour.

Shaping the Cheese

Once stirred, the curd is carefully poured into special cheese molds. It rests there for about 15 minutes. Then, it's pressed firmly to squeeze out any extra liquid. The cheese is also turned over a few times to help it drain properly.

Salting and Aging

After the cheese is shaped and pressed, it's taken out of the mold. It's turned upside down and marked with a special farm stamp. Then, it's sprinkled with salt. After salting, the cheese is placed in a salty water bath called brine. It stays in the brine for 1 to 6 days, depending on how big the cheese is.

Finally, the cheeses are moved to a special room called a curing room. This is where they get to age and become even more delicious. The cheesemakers turn the cheeses over many times while they age. This helps them ripen evenly until they reach the perfect taste and texture.

| Emma Amos |

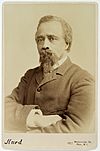

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |