Champion-Providence Mine facts for kids

The Champion-Providence Mine was a large gold mining operation in Nevada City, California. It started as two separate mines, the Champion and the Providence. After the California Gold Rush, these mines joined together. Later, they became part of the Champion Group, which grew to include several other mines. This group became one of the most successful mining operations in the Nevada City area, along with the North Star Mine. The North Star Mine eventually bought the Champion Group. The Champion-Providence Mine stopped operating in 1920.

Contents

Champion Mine: A Gold Mining Story

Champion Mine: Early Days

The Champion mine was located near Deer Creek, about a mile west of Nevada City. It sat at an elevation of about 2,330 feet (710 meters). The mine property originally covered 27 acres (11 hectares).

The Champion mine started as a claim called "New Years" in 1851. It didn't open as quickly as the nearby Providence mine. By 1888, its main shaft went down 300 feet (91 meters) at an angle. Miners had also dug 350 feet (107 meters) of tunnels. In 1892, the Champion mine joined with the Merrifield mine and eight other claims. They dug a long tunnel, 3,000 feet (914 meters) long, from Wolf Creek to drain water from the mine. This tunnel met the main shaft 600 feet (183 meters) down. Even with some breaks due to a legal fight with the Providence mine, the Champion shaft reached 2,400 feet (732 meters) deep by 1902.

Champion Mine: Gold Veins and Rocks

The gold veins in the Champion mine ran north to south and angled down to the east. These veins were usually 1 to 6 feet (0.3 to 1.8 meters) wide, averaging about 2.5 to 3 feet (0.76 to 0.91 meters). The gold was found where two different types of rock met: a hard, granite-like rock called syenite and a softer rock called slate.

The Champion Mine owned ten different claims, including Merrifield, New Years, and Ural. There were two main gold veins: the Merrifield vein to the east and the New Years vein to the west. The Merrifield vein was very long, stretching over 11,000 feet (3,353 meters). It was found in granite-like rock. The Ural vein was parallel to the Merrifield vein, about 500 feet (152 meters) to the west. It followed the edge of the granite-like rock and another rock type called Calaveras formation. This vein was also very long, about 7,500 feet (2,286 meters). The gold ore in these veins was mostly milky white quartz with about 6% sulphides (minerals containing sulfur), like pyrite (fool's gold), chalcopyrite, galena, and sphalerite.

Champion Mine: How They Worked It

Miners worked the Champion mine through an angled shaft that was 900 feet (274 meters) long. They dug eight levels (tunnels) from this shaft. Some tunnels went 528 feet (161 meters) north, and others went 180 feet (55 meters) south. A long drain tunnel helped keep surface water out of the mine.

They found two main areas of gold ore. One was north of the shaft and had a lot of gold, but it wasn't as rich. The other, south of the shaft, had very rich gold. As they dug deeper, the northern gold area angled more to the south, eventually crossing the main shaft. When the two gold areas got closer, the northern one became richer. Mining costs were low, about $2.50 to $3 per ton of ore. The ore was easy to process, even though some parts were very rich, sometimes worth $150 to $200 per ton. On average, the ore was worth about $80 per ton, with about $10 of that being silver. The company used its own special plant to process the gold.

The mine didn't have much water, so a small pump was enough to keep it dry. Air shafts (winzes) helped with ventilation.

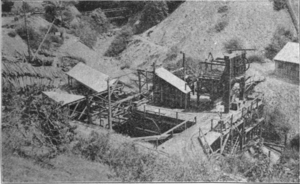

The ore was crushed in a mill with fifteen heavy stamps. Each stamp weighed 750 pounds (340 kg) and dropped 90 times a minute. They crushed about 1.67 tons of ore per day. After crushing, the gold-containing minerals (sulphurets) were collected using special machines called Frue concentrators. The mine also had a chlorination plant, which used chemicals to get more gold from the sulphurets. This process cost about $8 per ton. The mine used water power from three large water wheels to run its pumps, hoists, and mill.

In 1893, 56 men and boys worked underground, and three worked in the mill. Five men worked at the chlorination plant. Miners earned $3 per day.

Providence Mine: Another Gold Story

Providence Mine: Early Days

The Providence Mine was located on the south side of Deer Creek, also about a mile west of Nevada City. It was slightly higher than the Champion mine, at 2,340 feet (713 meters) elevation.

The Providence Mine was one of the first claims in the area, started in 1858. It was first worked from 1861 to 1867. Getting the gold from the ore was hard at first. It became successful around 1870 after they started using the chlorination process. By 1886, the main shaft was 1,100 feet (335 meters) deep. Miners had dug eleven tunnels, the longest being 3,600 feet (1,097 meters) long. They also dug a 547-foot (167-meter) tunnel to reach the Ural vein. The mine closed in 1891 but reopened the next year. In 1894, the Providence and Champion mines had a big legal fight over who owned certain parts of the gold veins. This fight ended in 1902 when the Champion company bought the Providence mine. Before being bought, the Providence mine had dug down 1,750 feet (533 meters) and was said to have produced $5,000,000 worth of gold.

Providence Mine: How They Worked It

The Providence property covered 154 acres (62 hectares) and had two main gold veins. The main shaft was on the eastern vein, called the Providence vein. This vein was large, ranging from 2 to 20 feet (0.6 to 6 meters) wide, averaging over 6 feet (1.8 meters). They found four rich areas of gold ore, each 150 to 320 feet (46 to 98 meters) long. All these rich areas angled north.

The western vein was reached by a 600-foot (183-meter) tunnel from the Providence vein. The gold ore in this western vein was very rich, about 5 feet (1.5 meters) wide.

The mine used a Burleigh compressor and a National drill for digging. They used Safety Nitro No.2 powder as an explosive. The mine had a large mill with forty stamps to crush the ore. Twenty of these stamps were working. The entire operation used water power from a fall of 380 feet (116 meters) at the mill and 320 feet (98 meters) at the hoisting works. They also had steam engines in case the water supply was low. In 1893, 25 men worked at the mine, earning $3 per day.

Champion Group: A Bigger Mining Company

By 1919, the Champion Group had grown to include many mines: Providence, Home (Cadmus), Merrifield, Spanish, Wyoming, and Nevada City mines. The company that owned them was the North Star Mine Company, based in New York City. George B. Agnew was the president, Arthur De Wint Foote was the manager, and his son, Arthur Burling Foote, was the superintendent.

The Champion Group owned about 440 acres (178 hectares) of land. This included many claims like Bavaria, Champion, Providence, and Nevada City. The Providence, Champion, Nevada City, Wyoming, and Home mines were the main ones that produced gold. Together, they were reported to have produced between $8,000,000 and $20,000,000 worth of gold, though the higher number is likely too large.

The Champion company bought the Providence property in 1902. In 1905, Champion had another legal dispute with the Home (Cadmus) mine. This was settled in 1907 when Champion bought the Home mine. The Home and Cadmus mines had been developed with short tunnels and shallow shafts until 1896. By 1902, the Home shaft was 700 feet (213 meters) deep, and they had a 30-stamp mill.

The Nevada City (or Gold Hill) mine, where the northern part of the Ural vein was worked, was also bought by Champion after some legal issues. This mine had two angled shafts, one 1,000 feet (305 meters) deep and another 1,100 feet (335 meters) away. From 1907 to 1911, the Champion mines faced challenges because money was spent on legal fees instead of improving the mines. Work stopped in June 1908, but some miners continued working independently. In 1909, the mine was put up for sale with a bond, but the deal fell through, leading to more lawsuits. In 1911, the North Star Mines Company took over the property. After exploring it, they bought the Champion Group. The North Star company then worked to drain the Champion shaft down to its 2,400-foot (732-meter) bottom level. They also reopened and extended tunnels to reach new gold areas. By 1914-1915, most of the gold came from the Nevada City mine.

It's hard to know the exact total gold production because records are incomplete. Estimates range from $8,000,000 to $20,000,000. The Champion Company alone produced over $2,864,528 from 1893 to 1913. This doesn't include the gold from Providence or Home mines before Champion bought them. It's thought that the combined production of the Ural and Merrifield veins was between eight and nine million dollars.

Champion Group: Mining Conditions

The gold veins in these mines were different from those in Grass Valley. This meant they needed different ways to support the tunnels with wood (timbering) and different mining methods. The veins were usually at least 2 feet (0.6 meters) thick and angled down at about 35 to 40 degrees. This meant less shoveling and less waste rock to move. The ore didn't contain "specimen ore" (large, visible pieces of gold). About 6% of the ore was concentrates, which held about 30% of the gold's value. The ground was heavy, so timbering was expensive. The wooden supports only lasted about a year and a half. Miners had to be careful in the tunnels and digging areas. In 1916, the mines weren't making enough money to cover costs. But by 1919, conditions had improved, and the quality of the ore was better, especially from the deeper parts of the Providence mine.

Champion Group: Processing the Gold

The mill had 40 heavy stamps, each weighing 1,250 pounds (567 kg). Ore came into the mill on a tramway and went over screens. Then, the stamps dropped 106 times per minute to crush the ore. After crushing, the gold was separated using special plates. The crushed ore (pulp) then went through a series of steps to separate the gold. It was sent to sand pumps, then to hydraulic classifiers, which separated it by size. The fine material (slime) went to thickeners. The sand was concentrated using special tables. The concentrated material was then de-watered and ground in a tube mill. Any leftover material went to other machines for further processing. The final ground concentrate flowed over another plate to get more gold. Any material that was still too coarse went back to the tube mill to be ground again.