Chapin Mine Steam Pump Engine facts for kids

|

Chapin Mine Steam Pump Engine

|

|

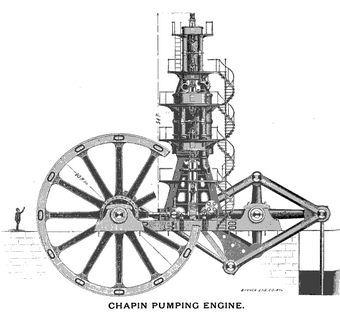

An drawing of the pump from the company that made it. Look at the person on the left to see how huge it is!

|

|

| Location | Kent St., Iron Mountain, Michigan |

|---|---|

| Area | 1 acre (0.40 ha) |

| Built | 1891 |

| Architect | Edwin P. Reynolds |

| NRHP reference No. | 81000305 |

Quick facts for kids Significant dates |

|

| Added to NRHP | July 9, 1981 |

The Chapin Mine Steam Pump Engine, also known as the Cornish Pump, is a giant steam-powered pump in Iron Mountain, Michigan. It is famous for being the largest steam-driven engine of its type ever built in the United States. Because of its importance, it is listed on the National Register of Historic Places and is a Michigan State Historic Site.

Contents

A Giant Engine for a Big Problem

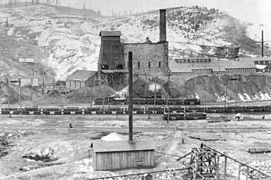

In 1878, iron ore was found in the area that is now Iron Mountain. The Chapin Mine opened a year later and quickly became the most successful mine in the region. However, it had a major problem: a large part of the valuable ore was under a swamp, and water was constantly leaking into the mine shafts.

Why Was the Pump Needed?

At first, the miners used smaller ground pumps to get the water out. But as they dug deeper, the flooding got worse. After several accidents, the mining company knew they needed a more powerful solution. In 1889, they hired the E. P. Allis Company from Milwaukee, Wisconsin, to build a massive water pump. The company's top engineer, Edwin P. Reynolds, designed a special "Cornish Pump" like the ones used in tin mines in Cornwall, England.

Building a Mechanical Giant

The pump was built between 1890 and 1891. It was installed at the surface, not deep in the mine. This was safer and more efficient for the steam power. A huge red sandstone building was constructed to protect it. This pump house was 60 feet (18 m) tall, with a foundation 23 feet (7.0 m) thick to support the machine's weight. The pump itself cost $82,000, which was a lot of money back then. The entire project cost about $250,000. The giant engine started its job of pumping water on January 3, 1893.

Moving and Retiring the Pump

In 1896, the ground under the engine shifted, which damaged the engine and its building. The pump had to be taken apart and put into storage in 1899.

Meanwhile, the Chapin Mining Company was growing. In 1901, it was bought by the Oliver Iron Mining Company, which was part of U.S. Steel. In 1907, the new owners decided to bring the giant pump back. They put it back together at a new spot near a different mine shaft. This time, it was housed in a metal building. The pump worked there until 1914, when new electric pumps took over.

The Chapin Mine closed for good in 1932 after producing over 27 million tons of iron ore. Two years later, the company gave the giant steam engine to Dickinson County to be a tourist attraction.

What Makes This Engine Special?

The Chapin Mine Steam Pump Engine is a massive machine.

- It is 54 feet (16 m) tall.

- Its flywheel, a huge wheel that keeps the engine running smoothly, is 40 feet (12 m) across and weighs 164 short tons (149 t).

- The whole engine weighs an incredible 600 short tons (540 t).

- It was so powerful it could produce over 1,200 horsepower (890 kW).

- It used 11,000 short tons (10,000 t) of coal each year to run.

The engine was connected to a series of eight pumps that went deep underground, with the lowest one being 1,500 feet (460 m) down. Each pump pushed water up to the next one, carrying it to the surface in eight steps. Together, they could pump 3,400 US gallons (13,000 L) of water every minute.

Even though it's called "The Cornish Pump," it's not a true Cornish engine. It was just named that because it was similar to engines used in Cornwall's mines.

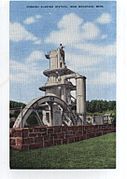

The Engine Today: A Museum Star

The engine was almost taken apart and melted down for scrap metal during World War II. Luckily, people in the community saved it.

In 1978, the Menominee Range Historical Foundation took over care of the engine. They built a museum around it, which opened in the early 1980s. Today, the museum is called the Cornish Pumping Engine and Mining Museum. Visitors can see the giant pump up close and learn about the area's mining history. The pump has been named a National Historic Mechanical Engineering Landmark for its amazing design.

Gallery

| Anna J. Cooper |

| Mary McLeod Bethune |

| Lillie Mae Bradford |