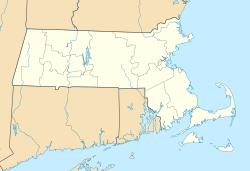

Dorchester Pottery Works facts for kids

Quick facts for kids |

|

|

Dorchester Pottery Works

|

|

|

|

| Location | 101-105 Victory Rd., Boston, Massachusetts |

|---|---|

| Area | 0.5 acres (0.20 ha) |

| Built | 1914 |

| NRHP reference No. | 85000318 |

| Added to NRHP | February 21, 1985 |

The Dorchester Pottery Works was a famous factory in Boston, Massachusetts. It made special clay items called stoneware. George Henderson started the factory in 1895. It closed in 1979. Today, the main building is a historic landmark. It was added to the National Register of Historic Places in 1985.

Contents

What is the Dorchester Pottery Works?

The Dorchester Pottery Works is in the Dorchester area of Boston. It is near a shopping center and train tracks. Only one main building remains today. It is a brick factory building. This building holds a huge oven called a kiln.

This kiln building was empty for many years. It was boarded up to keep it safe. Now, it has been fixed up. In the past, there was another factory building. There was also the Henderson House. The Henderson House was where the owners lived. They also used it to show off their pottery. Sadly, these other buildings were destroyed.

The Kiln Building's Look

The kiln house has two floors. It is made of red bricks. A tall red brick chimney sticks out from one side. This chimney is about 60 feet high. The building is almost square. It measures about 45 feet by 49 feet. It stands about 25 feet tall.

The windows on the first floor are arched. They used to have nine-over-nine window panes. These windows have been rebuilt after being damaged. There are also wide entrances on the south and west sides. The building has simple decorations. These include different colored bricks on the chimney.

Inside the Kiln Building

Inside, the building is mostly one big open space. There is a second floor that acts like a balcony. This balcony has a large round opening in the middle. Steel poles hold up the roof of the second floor. The inside is about 14 feet high to the second floor. It is about 28.5 feet high to the top of the building.

The most important part inside is the huge kiln. This kiln is round and shaped like a beehive. It takes up most of the ground floor. The kiln is about 30 feet wide. It is about 12 feet tall. Its walls are about 4 feet thick at the bottom. The outer wall has nine firing holes. It also has an arched entrance to get inside. Strong iron bands wrap around the kiln. These bands help it expand and shrink safely when it gets hot and cools down.

Inside, the kiln is about 22 feet wide. It is about 10.5 feet high in the center. It is about 6.5 feet high near the sides. Brick shelves line the inner walls. These walls have a shiny surface. This shine came from glazes that turned into vapor during firing. The floor has special heat-resistant tiles. These tiles let heat and fire move through an underground path. This path leads to the chimney outside.

History of Dorchester Pottery

George Henderson started the Dorchester Pottery Works in 1895. He came from New Haven, Connecticut. Before this, he made pottery with a partner since 1884. The factory made useful stoneware for many years.

What Pottery Did They Make?

Over time, the pottery changed. At first, they made items for farms. These included feeders for chickens. They also made items for factories. Jewelry makers needed acid pots and dipping baskets. Henderson's popular foot warmer was called a "porcelain pig."

In 1940, they started making special gray and blue tableware. This pottery was shaped on a potter's wheel. It was called slipware. It had a shiny coating called a Bristol glaze.

The Giant Kiln

In 1914, Mr. Henderson built a huge beehive kiln. It was 28 feet wide. He designed it himself using bricks without mortar. Workers carefully stacked two or three train car loads of unfired pottery inside. Then, the opening was sealed. The kiln was slowly heated. It used 15 tons of coal and four cords of wood. The temperature reached 2500-3000 degrees Fahrenheit. After several days of cooling, the door was opened brick by brick. The finished pottery was then removed. The whole process took about one week.

Growth and Changes

In the 1920s, Dorchester Pottery also bought finished pottery from other companies. This included containers, jugs, and household items. At its busiest in the 1920s, the factory had 28 potters. By the 1950s, they made 1,700 different items. About 25% of these were tableware. By the 1960s, all their products were tableware.

In 1921, 23 people worked at the pottery. Most of them lived in Dorchester. George Henderson died in 1928. His son, Charles, and daughter-in-law, Ethel Hill Henderson, took over. George (the son) died in 1967. Ethel continued the business with her brother, Charles Allen Hill, and her sister, Lilly Yeaton. Ethel had been a teacher. She became the boss of the kiln. Her two children, George and Lillian, also helped.

The Great Depression made sales of commercial stoneware drop. Ethel started decorating the stoneware. She used designs from old New England. Her brother, Charles, added new color mixing ideas. He had been a chemistry teacher. Many artists decorated the pottery. Their names can be found on the pieces. Ethel died in 1971. Some pieces made after that time are signed "I.M.E.H.H." (In Memorial Ethel Hill Henderson).

The End of an Era

Even though the handmade pots were popular, they could not compete with cheaper factory-made items. The last time the big beehive kiln was used was in 1965. After that, they used smaller gas and electric kilns. The pottery works closed in 1979.

The Dorchester Pottery Works stayed open longer than other New England potteries. This was because it made many different products. It was also run by a family. They made many items. These included storage jars, beanpots, plates, pitchers, bowls, and vases. They also made special custom designs.

Some common designs included blueberries, cherries, pears, and pine cones. They also had ships, stripes, and whale patterns. These designs were painted with blue and white slip. Sometimes, they added shallow scratch work. Special orders might use green or gold colors. All pieces got a clear Bristol glaze. Most pottery pieces had a paper label or a stamp to show where they came from.

Materials and Methods

Until 1971, all the clay came from New Jersey. The blue color for the decorations came from Germany. From 1972, the clay came from Ohio. For over 80 years, the company used the same apple wood drying boards. These boards were used to stack unfired pottery. They came from another old company that Henderson bought.

The way they made pottery changed very little over time. It was a small factory where products were handmade. They used older methods that other big factories had stopped using. Pieces were mostly shaped by hand. Handles were added one by one. Pieces were dipped in glazes by hand. Shapes were made to fit custom orders.

What Happened Next?

In 1980, a fire destroyed the family home and the main production building. For almost 20 years, only one boarded-up building remained. It had a tall smokestack. After the pottery works closed, local groups tried to buy the kiln building. They wanted to create a museum. This plan did not work out.

In 2001, a group called Bay Cove Human Services bought the property. They fixed up the building for their own use. They kept the kiln room and the kiln itself. This part is still used for community exhibitions.

See also

| Selma Burke |

| Pauline Powell Burns |

| Frederick J. Brown |

| Robert Blackburn |