Dry pasta line facts for kids

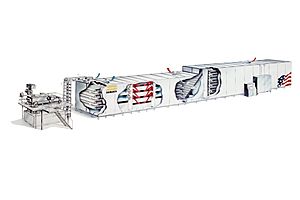

Dry pasta lines are big machines that make lots of dry pasta, like spaghetti or penne. These machines are used by companies to make huge amounts of pasta, from 500 to 8,000 kilograms every hour! A typical dry pasta line has two main parts: an extruder and a dryer.

Modern pasta lines use computers called programmable logic controllers to work almost by themselves. They are called "lines" because the pasta moves through many different machines, one after another. These lines can even run non-stop for up to six weeks!

How Pasta Lines Work: The Extruder

The extruder is the first main part of the pasta line. It does a few important jobs:

- It mixes flour and water to create dough.

- It kneads the dough to make it smooth and ready.

- It pushes the dough through a special metal plate called a "die." This die has holes in the shape of the pasta, like circles for penne or slits for spaghetti.

- It cuts the pasta to the right length.

For long pasta, like spaghetti, the extruder uses a rectangular die. For short pasta, like macaroni, it uses a round die. The extruder also uses a vacuum system. This system removes air from the dough, which makes the pasta stronger and better.

How Pasta Lines Work: The Dryer

After the pasta is shaped, it needs to be dried. The dryer makes sure the pasta has just the right amount of moisture. This stops it from going bad and makes it ready to be stored.

- Long pasta (like spaghetti) hangs vertically from long sticks as it moves through the dryer. This drying process can take about 6 to 9 hours.

- Short pasta (like penne or macaroni) sits on long conveyor belts with mesh screens. It usually dries faster, taking about 3 to 4 hours.

To dry the pasta correctly, the dryer carefully controls the air, heat, and moisture inside. This is very important for making good quality dry pasta.

What Happens After Drying

Once the pasta is perfectly dry, it's ready for the next steps: storage and packaging.

- Long pasta moves into a special area called an "accumulator." This part holds the sticks of pasta until they are ready. Then, a machine called a "stripper" gently removes the pasta from the sticks. It also trims the pasta to the exact length needed. After that, the pasta is sent to a packaging machine.

- Short pasta is usually stored in large storage containers called silos. Each different shape of pasta, like elbow macaroni or rotini, gets its own silo. From the silos, the pasta is then moved to be packaged in bags or boxes.