Dugald Clerk facts for kids

Quick facts for kids

Sir Dugald Clerk

|

|

|---|---|

|

|

| Born | 31 March 1854 Glasgow, Scotland, UK

|

| Died | 12 November 1932 (aged 78) Ewhurst, England, UK

|

| Nationality | Scottish |

| Citizenship | British |

| Occupation | Engineer |

| Known for | Designed the world's first successful two-stroke engine |

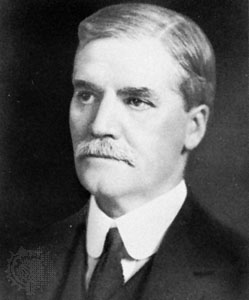

Sir Dugald Clerk was a Scottish engineer. He is famous for designing the world's first successful two-stroke engine in 1878. He got a patent for his invention in England in 1881.

Dugald Clerk studied engineering at Anderson's University in Glasgow. He also went to Yorkshire College in Leeds. Later, he started a company called Marks & Clerk with George Croydon Marks. This company helped people protect their inventions. He was made a knight in 1917, which is why he is called 'Sir'.

Contents

About Dugald Clerk

Dugald Clerk was born in Glasgow, Scotland, on March 31, 1854. His father, Donald Clerk, was a machinist.

He first learned about engineering by working for a company in Glasgow. From 1871 to 1876, he studied engineering at two different colleges. During the First World War, he led engineering research for the British Navy.

He married Margaret Hanney in 1883. Sir Dugald Clerk passed away in Ewhurst, Surrey, England, on November 12, 1932.

How Clerk Improved Engines

Dugald Clerk started working on his own engine designs in 1878. He wanted to make a better internal combustion engine. These engines create power by burning fuel inside them.

Before Clerk's work, some engines were not very efficient. For example, the Lenoir engine used a lot of gas. The Otto & Langen engine was better, but it used atmospheric pressure for power.

In 1876, Nikolaus Otto developed a new engine. It used a four-stroke cycle and compressed the fuel inside the cylinder. This made it much more efficient.

Clerk wanted to create an engine that also used compression. But he aimed for a two-stroke cycle. This would mean more power strokes, making the engine smoother and lighter.

His early experiments helped him develop the two-stroke cycle. By the end of 1880, he successfully built the "Clerk engine." This engine became a commercial product. It was the first to combine fuel compression with an ignition (spark) at every turn of the engine.

Clerk also wrote three important books about the history of oil and gas engines. These books included details about his own inventions.

The Clerk Cycle

In 1878, Clerk got a "Ready Motor" engine made by George Brayton. Clerk wanted to make it better. He added a spark plug and improved how it got fuel.

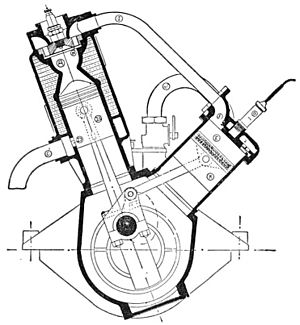

At first, Clerk used one cylinder to compress air and fuel, and another to create power. But he later changed his design. He decided to use the second cylinder only to move the air and fuel mixture into the main power cylinder. This pushed out the old exhaust gases.

The Otto cycle engine was patented in 1876. Clerk quickly followed with his two-stroke engine idea in 1880. His design was different enough not to copy Otto's four-stroke patent.

The Clerk cycle works like this:

- It has two cylinders: a pump cylinder and a motor (power) cylinder.

- The pump cylinder takes in a mix of gas and air.

- The motor piston moves out, opening a port to let out exhaust gases.

- When the exhaust is gone, the pump forces the fresh fuel mix into the motor cylinder. This pushes out any remaining burnt gases.

- The motor piston then moves back, compressing the fuel mix.

- The compressed mix is then ignited, creating power.

Clerk's engine used special valves for air and gas. It also had a port in the cylinder for exhaust. His big contribution was adding Otto-style compression to the two-stroke engine. This made it much more efficient for its time.

Today, two-stroke engines are common in large diesel engines. You can find them in ships and trains. These modern engines are still based on Dugald Clerk's original ideas.

Pumping Cylinder vs. Supercharger

Clerk's engine had two cylinders. One was the main working cylinder, and the other was an extra cylinder to help fill the main one. Some people thought this extra cylinder was the first supercharger.

However, Clerk himself said it was not a compressing pump. Its job was just to move the gases into the main cylinder. It pushed out the old exhaust gases and brought in the fresh fuel mix. So, it is usually called a "pumping cylinder" instead of a supercharger. It moved the mixture but didn't compress it much before it entered the main cylinder.

Clerk's Engine vs. Modern Two-Stroke Engines

Clerk's first design needed an extra pumping cylinder for each working cylinder. This made it hard to build smaller engines.

A big improvement came in 1894. An inventor named Joseph Day patented a simpler design. His design made it possible to build small, powerful two-stroke engines for everyday use.

Other inventors also helped improve two-stroke engines:

- Joseph Day designed a three-port two-stroke engine.

- Nash created a two-port two-stroke engine.

- Robson designed a two-stroke engine that used the space under the piston to help clear out exhaust.

- Fielding developed a uniflow two-stroke engine.

See also

- Joseph Day

- History of the internal combustion engine