- This page was last modified on 17 October 2025, at 10:18. Suggest an edit.

Howard & Bullough facts for kids

| Partnership | |

| Predecessor | Howard & Bleakley |

| Founded | 1856 |

| Headquarters |

Accrington, Lancashire

,

England

|

| Products | Power looms |

| Footnotes / references Tweedales and Smalley was formed by this companies executives. |

|

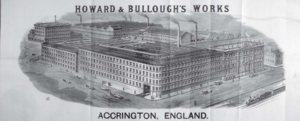

Howard & Bullough was a very important company that made machines for textile factories. They were located in Accrington, a town in Lancashire, England. In the 1860s, they were one of the biggest makers of power looms in the entire world. Power looms are machines that weave fabric much faster than people can by hand.

Contents

How Howard & Bullough Started

The company began in 1851 as Howard and Bleakley, with only four workers. In 1856, one of the founders, Bleakley, left the business. The company then changed its name to Howard & Bullough.

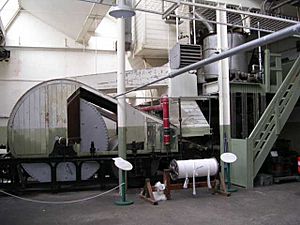

John Bullough, one of the founders, was a clever inventor. He had made a special part for handlooms called a "self-acting temple." This part helped keep the fabric even as it was woven. He also worked with William Kenworthy to create the famous Lancashire Loom, an improved power loom. By 1856, the company had grown to employ 150 people. John's son, James, joined the business in 1862.

At first, Howard & Bullough focused mainly on making looms. But over time, they started making all sorts of machines needed in a cotton mill. This included machines for spinning cotton into thread and preparing it for weaving.

A Big Company in the Textile World

John Bullough, born in 1837, passed away in 1891. By this time, his company, Bulloughs, was the world's largest maker of ring spinning frames. These machines were vital for making strong cotton thread. John Bullough became very wealthy, even owning the Isle of Rùm in Scotland. He was known as the first millionaire from cotton machine manufacturing.

Howard & Bullough was one of the largest manufacturing companies in the country. At its busiest, their factory, called Globe Works, was huge. It covered about 52 acres (21 hectares) and employed almost 6,000 workers. A large part of their machines, about 75%, were sent to other countries around the world.

Some of the company's top managers, Edmund and Samuel Tweedale and Joseph Smalley, left to start their own business. Their new company was called Tweedales and Smalley. They made spinning machines for factories, including the Newhey Spinning Mill in 1893 and the Drezna factory in Russia in 1897.

The 1914 Lock-Out

In 1914, a disagreement happened at the factory. The company's managers refused to meet the demands of a workers' group called the Amalgamated Society of Engineers. The workers wanted their union to be officially recognized and for everyone to earn a certain minimum wage.

Because of this, about 600 engineers at the factory went on strike on July 2nd. Six days later, the company's management decided to "lock out" all nearly 5,000 men and boys who worked there. This meant they were not allowed to come to work.

During this time, World War I had just begun. The British army was looking for new soldiers. The Mayor of Accrington helped to create a special group of soldiers called the Accrington Pals. Many of the locked-out workers, who had no income, decided to join this group and serve their country.

During the Second World War, Howard & Bullough changed what they made. Instead of textile machines, they produced weapons and parts for the war effort. This included things like bayonets, shells, gun carriages, and aircraft parts.

Changes and Closure

In the 1930s, during a difficult economic time, several large textile machinery companies decided to merge. Howard & Bullough joined with Platt Brothers, Brooks & Doxey, Asa Lees, Dobson & Barlow, Joseph Hibbert, John Hetherington, and Tweedales and Smalley. They formed a new, bigger company called Textile Machinery Makers Ltd.

Even after the merger, the individual companies continued to use their own names until the 1970s. Eventually, they were all combined into one company called Platt UK Ltd. In 1991, the company changed its name again to Platt Saco Lowell. Sadly, the famous Globe Works factory in Accrington closed its doors in 1993.

Clever Inventions by the Bulloughs

James Bullough made many improvements to the power loom. He invented the "self-acting temple," which helped keep the woven cloth at the correct width. He also invented the weft fork in 1841, which detected if the weft thread (the thread that goes across) broke. Another invention was a loose reed, which allowed the loom to move back if a shuttle got stuck. James also created a simple bell that would ring if a warp thread (the thread that runs lengthwise) broke on his loom. He worked with William Kenworthy to put these ideas together and create the improved power loom known as the Lancashire Loom.

John Bullough, along with James Whittaker and John Walmsley, also developed an important machine. In 1852, they patented a machine that could prepare two warps (sets of threads) at the same time and wind them onto two beams. This made the process of preparing threads for weaving much faster.

Helping the Community

Howard & Bullough followed a tradition of the time by trying to improve the lives of their workers and the local community. They did this through acts of kindness and giving, known as philanthropy. For example, the company gave James Bullough Park to the town of Accrington in 1913. In 1926, they also provided the grounds for the Globe Tennis Club.

See also

- George Bullough