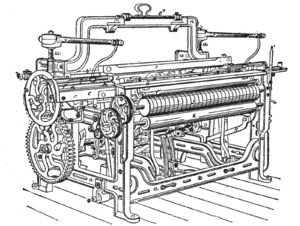

Lancashire Loom facts for kids

The Lancashire Loom was a special machine that helped make cloth. It was a power loom invented by James Bullough and William Kenworthy in 1842. This loom was "semi-automatic." This means it could do a lot of work by itself, but it still needed to be stopped to put in new thread. The Lancashire Loom was very important for the cotton industry in Lancashire for about 100 years.

John Bullough: The Inventor

John Bullough (1800–1868) was an inventor from Accrington, England. He started his career as a handloom weaver, making cloth by hand. Unlike many other weavers at the time, Bullough was excited about new machines. He liked Edmund Cartwright's power loom, which was invented in 1785.

While some people protested new machines, like during the power-loom riots in Lancashire in 1826, Bullough worked to make looms better. He invented several important parts:

- A "self-acting temple" that kept the woven cloth at the right width.

- A "loose reed" that helped the loom if a shuttle got stuck.

- A simple warning device that rang a bell when a warp thread broke.

Bullough moved to Blackburn and worked with William Kenworthy. Together, they used his inventions to create a much better power loom. This loom later became known as the "Lancashire Loom." John Bullough had to leave Blackburn because some angry handloom weavers were upset about the new machines.

Later, he settled back in Accrington and started a company called Howard & Bullough with John Howard. Their factory, Globe Works, was next to the Leeds-Liverpool Canal. Here, Bullough invented another important machine called the "slasher," which helped the company become very successful. Howard & Bullough grew to be one of the biggest manufacturers in the country. At its busiest, the Globe Works employed almost 6,000 workers and covered a huge area. About 75% of their machines were sold to other countries.

Howard & Bullough later became part of a larger group and eventually closed in 1993.

How the Loom Worked

From 1830 onwards, power looms were constantly being improved. The Lancashire Loom brought together many of these new ideas.

Here are some key improvements that led to the Lancashire Loom:

- In 1830, Richard Roberts improved his loom with geared wheels and parts to control many threads.

- Inventors like Hornby, Kenworthy, and Bullough (1834) created the "vibrating reed."

- John Bullough (1835) improved how the loom stopped when a thread broke.

- William Kenworthy and James Bullough (1841) developed a better "temple" (a device that holds the cloth) and a simple way for the loom to stop automatically.

By 1841, the loom was almost fully automatic. This was the Kenworthy and Bullough Lancashire Loom. Before this, a weaver could only operate one loom, which made about 120 to 130 "picks" (when the shuttle passes through the threads) per minute. With the new Lancashire Loom, one weaver could manage up to six looms! Each loom could make 220 to 260 picks per minute. This meant they could produce 12 times more cloth! The power loom became known as a "perfect machine" because it made better quality cloth for less money. It was a huge economic success.

Other important improvements included:

- John Bullough (1842) invented the "loose reed," which doubled the loom's operating speed.

- John Sellers (1845) created the "Burnley Brake," a special brake for the loom.

Loom Movements

Weaving cloth on a loom involves three main actions:

- Shedding: This is when the long threads (called the warp) are divided into two lines. This creates a space for the shuttle to pass through.

- Picking: This is when the shuttle is shot from one side of the loom to the other. The shuttle carries the crosswise thread (called the weft).

- Beating-up: This is when a part called the reed pushes each new weft thread tightly against the cloth that has already been woven.

Economic Impact

The biggest benefit of the Lancashire Loom was that it was semi-automatic. If a warp thread broke, the weaver was told. If the shuttle ran out of thread, the machine would stop. This meant that one worker could operate four or more looms at once. Before, they could only work one loom. In fact, the term A Four Loom Weaver was used to describe these workers. This greatly reduced the cost of labor. In some factories, a worker might even operate six or eight looms, depending on the type of thread being used.

By 1900, the Lancashire Loom faced competition from the Northrop Loom. The Northrop Loom was fully automatic, meaning it could run with even less human help, and more of them could be managed by one person. The Northrop Loom was good for making coarse (rough) cloth. However, for fine cotton, the Lancashire Loom was still preferred. By 1914, Northrop looms made up 40% of the looms in American factories. But in the United Kingdom, where labor costs were not as high, they only made up about 2% of the market.

| Misty Copeland |

| Raven Wilkinson |

| Debra Austin |

| Aesha Ash |