Queen Street Mill facts for kids

Queen Street Mill

|

|

| Cotton | |

|---|---|

| Weaving mill | |

| Current status | Closed 12 Mar 1982 |

| Architectural style | Single storey |

| Location | Harle Syke, Burnley, Lancashire, England |

| Owner | Queen Street Manufacturing Company |

| Further ownership |

|

| Current owners | Lancashire Museums |

| Coordinates | 53°49′N 2°12′W / 53.81°N 2.20°W |

| Construction | |

| Built | 1894 |

| Completed | 1895 |

| Floor count | 1 |

| Design team | |

| Awards and prizes and listings | A Grade I listed building.No. 1416482(2013-12-25) |

| Power | |

| Date | 1894 |

| Engine maker | William Roberts of Nelson |

| Engine type | Tandem compound |

| Valve Gear | Corliss valves operated by Dobson trip gear |

| rpm | 68 |

| Installed horse power (ihp) | 500 |

| Transmission type | Direct drive to line shafts |

| Boiler configuration | |

| Boilers | Twin Lancashire boilers, coal fired |

| Pressure | 140 |

| Equipment | |

| Date | 1894 |

| Manufacturer |

|

| No. of looms | 990 (now 308) |

Queen Street Mill is a really special old weaving mill in Harle Syke, a small area near Burnley, England. It's so important that it's a Grade I listed building, which means it's protected because of its history. Today, it's a museum and even has a cafe! You can visit it for public tours between April and November.

This mill was built way back in 1894 for the Queen Street Manufacturing Company. It stopped making cloth in 1982, but thankfully, it was saved and turned into a museum. What makes it super unique is that it's the only working steam-powered weaving mill left in the whole world! Because of this, it won an Engineering Heritage Award in 2010. After some changes, the museum is now open again on certain days, letting visitors see how things used to be.

Contents

Where is Queen Street Mill?

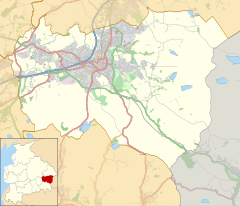

Queen Street Mill is located in Harle Syke, a suburb of Burnley. Burnley is an industrial town in the North West of the United Kingdom. Harle Syke is about 4 kilometers (2.5 miles) from Burnley town center.

It's also about 35 kilometers (22 miles) north of Manchester and 42 kilometers (26 miles) east of Preston. These were other big industrial towns during the Industrial Revolution. Harle Syke is on high ground near the River Calder. This small area once had seven cotton mills, or weaving sheds, with streets laid out like a grid.

A Look Back: The Mill's History

The Queen Street Mill Manufacturing Company started in 1894. They raised £20,000 to build the mill between 1894 and 1895. At first, they only had one Lancashire boiler because money was tight. The weaving shed was a single-story building, while the front part of the mill had three stories.

All the looms, which are machines that weave cloth, were bought from Burnley companies like Pemberton & Co. and Harling & Todd Ltd. These original looms are still there today! The mill started with 900 looms that made plain, unbleached cloth called 'grey cloth'. When they needed to make more, they added 366 more looms at a nearby mill called Primrose Mill.

How Cloth Was Transported

Finished cloth was first taken by horse and cart, then by train, to other places for bleaching and dyeing. Around 1910, some former mill workers bought two steam-powered lorries to help with transport. However, these lorries were taken for war work in 1915, and horses had to be used again for a short time.

In 1913, the mill upgraded its steam engine to make it more efficient. This work was done during the annual holiday week. The company's financial setup meant that the original machines were kept for a long time. Mains electricity wasn't even installed until 1947!

The Harle Syke Strike of 1915

Weavers were paid based on how much cloth they made. A good weaver could earn 24 shillings a week. Workers in Harle Syke were often paid a little less than others. In August 1915, this led to a strike that lasted several weeks. Some workers, who also owned shares in the mill, didn't join the strike. The Weavers' Union called them "Knobsticks" for not supporting their fellow workers. The issue was finally settled in December 1915 when a "War Bonus" was introduced, which gave weavers the pay raise they wanted.

The Fire of 1918

A serious fire broke out in October 1918. Luckily, the boilers and the engine were not damaged. The mill was back up and running just 10 days later! However, the front of the mill was damaged and had to be rebuilt. It was then made into a single-story building. During the rebuilding, the looms were moved to the nearby Primrose Mill. The mill's engine, originally called Prudence, was renamed Peace to honor soldiers who died in the First World War.

Queen Street Mill as a Museum

By early 1982, the mill was only using 440 looms and couldn't make enough money to stay open. It closed on March 12, 1982. But the mill was saved by Burnley Borough Council in 1983. It reopened in April 1986 as a working textile museum.

Later, Lancashire County Council's Museums Service took over. They did a lot of work to fix up the mill with help from other groups. It reopened again in 1997. The museum still makes cloth during demonstrations, and its machines are considered very important to the country's history.

What You Can See at the Museum

Besides the original machines, the museum also shows other textile machines they own or are fixing. They even weave special orders for customers! For example, they make blue and white shirt fabric for a company that sells Victorian-style work clothes. They also weave woollen Jewish prayer shawls.

You can see different types of looms, like a large Hattersley Standard Loom and a smaller, foot-pedal operated Hattersley Domestic Loom. There's also a modern Sulzer and a Saurer rapier loom that works very fast. The museum has a collection of tools used to make and fix shuttles, which are parts of the loom.

Recent Closures and Reopenings

In November 2015, the local council announced they would stop funding five of their museums, including Queen Street Mill. They were set to close in March 2016, but got a six-month extension and stayed open until September 2016.

The museum closed on September 30, 2016, except for school groups who had booked visits. For a while, there were talks about a new group taking over the museum. In April 2018, it was announced that the museum would reopen on Fridays, Saturdays, and Sundays from July 7 to October 28, 2018, and then again between Easter and the end of October in 2019.

Mill Design and Architecture

When it was first built, the mill had a four-story main building and a very large single-story weaving shed. After the fire in 1918, it was rebuilt as a single-story building. Some of the weaving shed space was used for a new area to prepare the yarn.

When the mill closed in 1982, Burnley Council changed it again. The weaving shed was divided, with some parts used for businesses and other parts for visitors. The mill has a 37-meter (121-foot) tall chimney and a large water storage area called a lodge. In 2013, the entire site was given Grade I listed status, protecting all its buildings.

The weaving shed was originally huge, about 170 meters (558 feet) by 160 meters (525 feet). It had special north-facing roof windows that let in natural light. This shed held 990 looms. The main building on Queen Street had the boiler room, engine house, and a four-story warehouse. Different floors were used for storing yarn, offices, and preparing the threads for weaving. After the fire, the ground floor was rebuilt for winding and preparing yarn, and some looms were removed.

How the Mill Was Powered

The mill gets its power from steam, which is made by two Lancashire boilers. These boilers were built by Tinker, Shenton & Co. The first one was installed in 1895, and the second in 1901. Water for the boilers is now supplied by a special pump installed in 1956.

The boilers were once fed coal by hand, but automatic machines were added in 1962. Today, only the 1901 boiler is used, and it's still fed by hand. Coal used to come from a local mine, but now it's imported from places like the United States and Russia due to stricter pollution rules. At its busiest, the mill burned 6 tonnes of coal a day, but now it uses only about 10 tonnes a month.

The steam, heated to 100 pounds per square inch (psi), powers the original steam engine. This engine was built by William Roberts of Nelson in 1895. It's a powerful 500-horsepower engine that has never been moved and still runs perfectly. It turns a large 4.3-meter (14-foot) flywheel at 68 rotations per minute. Power is then sent from the engine to the looms through a series of spinning rods called line shafts.

The Mill's Equipment

Queen Street Mill is special because it still has almost all its original equipment. When yarn arrives at a weaving mill, it's on different sized bobbins. These need to be wound onto smaller bobbins called pirns to fit into the shuttles used by the looms. The mill still has machines for this, operated by one person.

Preparing the Warp Threads

The warp threads (the long threads in weaving) need careful preparation. They are taken from 300 bobbins on a V-shaped frame and wound onto a large roller called a beam. Four or five of these beams are then combined to make a huge beam with about 2000 threads.

These threads then go into a Cylinder Tape Sizing Machine (made in 1919). Here, the threads pass through a special liquid called "size" to make them stiffer and smoother. This size is a unique mix of flour, soft soap, and tallow, specific to this mill! The threads are then dried over steam-heated cylinders and wound onto the final "weavers beam."

Setting Up the Loom

Next, the weavers beam is placed on a "Drawing-in frame." Here, each thread is carefully passed through small loops called healds, and then through a comb-like part called a reed. This job was done by a "reacher-in" (often a young boy) and a "loomer." The reacher-in would hand each thread to the loomer in the correct order. The mill still has two Drawing-in frames.

Sometimes, if the same type of cloth was being made again, a machine called a Barber-Colman knotter could tie the new warp threads to the old ones. This saved a lot of time, taking only 20 minutes instead of starting from scratch.

The Weaving Shed

Once the weavers beam was ready, it was taken to the weaving shed. One weaver would look after 6 or 8 Lancashire Looms, with a "tackler" (a supervisor) making sure they all worked correctly. Today, there are 308 looms from 1894, built by Pemberton or Harling & Todd. These would have needed 65–80 weavers and 3 tacklers. At its busiest, the mill had 990 looms, all powered by overhead line shafts.

Queen Street Mill in Movies and TV

The weaving shed at Queen Street Mill has been used as a filming location for several movies and TV shows.

- It appeared in the 2010 film The King's Speech.

- It was used to represent the Milton steam mill in the BBC series North & South.

- It was featured in Life on Mars.

- It appeared in the 2015 BBC adaptation of An Inspector Calls.

The mill has also been shown in documentaries, including Channel 4's 2014 series Hidden Villages, presented by Penelope Keith.

See also

- Grade I listed buildings in Lancashire

- Listed buildings in Briercliffe

- Bancroft Shed

- Helmshore Mills Textile Museum

- Textile manufacturing