Line shaft facts for kids

A line shaft was a long, spinning rod used to share power from one big engine to many machines in a factory or workshop. Imagine a giant spinning stick running through a building! Before small electric motors were invented, line shafts were super important. They helped power everything from spinning machines to saws.

The main power source could be a water wheel, a steam engine, or even animals. This power would turn the line shaft, and then a system of belts, pulleys, and gears would carry that power to each machine. It was like a giant mechanical network!

Contents

How Did Line Shafts Work?

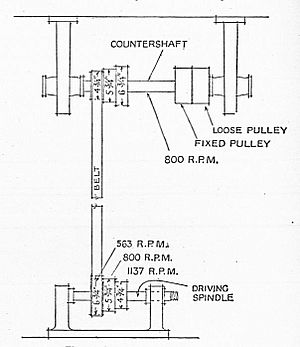

Line shafts were usually hung from the ceiling and ran across a room. One pulley on the shaft would get power from the main engine. Other pulleys on the same shaft would then send power to individual machines.

In factories with many similar machines, the setup was quite organized. But in workshops with different kinds of tools, the system could look a bit messy, with shafts going in many directions and pulleys of all sizes.

The shafts were usually made of strong steel. They were held up by hangers with special parts called bearings. These bearings needed to be kept oiled so they wouldn't get too hot or break. There were even special workers whose job was just to oil these bearings!

Belts and Pulleys

Most of the time, power moved from the line shaft to machines using flat belts made of leather or strong cotton. These belts would loop around pulleys on the line shaft and then around pulleys on the machines.

- Changing Speed: Different sized pulleys were used to change how fast a machine spun. For example, a big pulley on the line shaft turning a small pulley on a machine would make the machine spin much faster.

- Stopping Machines: Sometimes, two pulleys were placed side-by-side on a shaft. One was "fast" (fixed to the shaft), and the other was "loose" (spun freely). Workers could move the belt from the "fast" pulley to the "loose" one to stop a machine without turning off the whole line shaft. This was very handy!

A Brief History of Line Shafts

Line shafts started appearing in the 1700s, but they became super common in the late 1800s during the Industrial Revolution. They were used everywhere: in factories, woodworking shops, sawmills, and even places that ground grain into flour.

In 1828, an inventor named Paul Moody in the U.S. started using leather belts instead of metal gears to move power. This idea spread quickly because it was more efficient and quieter.

By the end of the 1800s, some factories had more than a mile of line shafts in one building!

The Rise of Electricity

In the early 1900s, factory electrification began. At first, electric motors were very big. So, new factories would use one large electric motor to power the entire line shaft system.

But soon, smaller electric motors became available. This was a game-changer! Factories started putting a small electric motor on *each* machine. This was called "individual electric drive." It meant you didn't need all those long, noisy line shafts anymore.

By the mid-1900s, most line shaft systems were gone. Today, you'll only find a few of them still working, mostly in museums or historical sites.

Why Were Line Shafts Replaced?

While line shafts were amazing for their time, they had some big downsides compared to individual electric motors:

- Wasted Power: A lot of power was lost due to friction in the shafts and belts.

- Noise: Factories with line shafts were very loud.

- Maintenance: They needed constant oiling and fixing.

- Danger: The moving belts and shafts could be dangerous for workers.

- Layout Problems: Factories had to be designed around where the shafts could go, not always in the best way for making things.

- Space: The shafts and belts took up a lot of room, blocking light and ventilation.

- Dust and Oil: Belts created dust, and oil dripped from the overhead shafts.

When factories switched to electric motors, workers were healthier (less sick time), and production went up! It was a huge improvement for industry.

Where Can You See Old Line Shaft Systems?

Even though most are gone, some places still have original or reconstructed line shaft systems that you can visit:

Original Systems

- Queen Street Mill, Burnley, UK — You can see line shafting powering 600 looms!

- National Slate Museum, Wales — Original equipment powered by a huge water wheel.

- East Broad Top Railroad and Coal Company, Pennsylvania, USA — A partially working machine shop.

- Hanford Mills Museum, New York, USA — An operable sawmill and gristmill.

- Sierra Railroad Shops, California, USA — An operable machine shop and blacksmith shop.

Reconstructed or Demonstration Systems

- Hagley Museum and Library, Delaware, USA — Shows how old powder mills worked.

- Henry Ford Museum and Greenfield Village, Michigan, USA — Has many old machine tools.

- Boott Mills, Lowell, Massachusetts, USA — Shows power looms working with line shafts.

- Silver Dollar City, Missouri, USA — Has woodworking tools and bakery machines powered by line shafts.

See also

- Lineshaft roller conveyor – a modern use of a long shaft to drive rollers

Images for kids