Lathe facts for kids

A lathe is a cool machine that helps people make things by spinning them around really fast. Imagine a potter's wheel, but for wood, metal, or even glass! It holds a piece of material, spins it, and then a worker uses special tools to shape it.

Lathes can make all sorts of things, like screws, candlestick holders, cue sticks, table legs, bowls, and baseball bats. They are also used to create parts for musical instruments, crankshafts, and camshafts.

Contents

Types of Lathes

Woodworking Lathes

Woodworking lathes are the oldest type of lathe. All other kinds of lathes came from these simple designs. With a woodworking lathe, a worker holds shaping tools by hand against the spinning wood. There's a metal bar called a "tool rest" that helps them hold the tools steady. After shaping, people often use sandpaper on the spinning wood to make it smooth. The tool rest is usually taken away during sanding to keep hands safe.

Many woodworking lathes can also make bowls and plates. The bowl or plate is held by one side of the lathe, often attached to a metal plate. This lets the worker shape both the inside and outside of the piece. You can find more details on the woodturning page.

Most woodworking lathes spin between 200 and 1,400 times per minute. For most work, spinning a little over 1,000 times per minute is best. Larger pieces need to spin slower.

Duplicating Lathes

A special kind of lathe is the duplicating or copying lathe. It's also known as a Blanchard lathe, named after its inventor, Thomas Blanchard. This lathe can make many identical shapes from one original pattern. It changed how gun stocks were made when it was invented in the 1820s.

Patternmaker's Lathes

These lathes are used to make patterns for foundries, which are places that make metal castings. These patterns are often made from wood or plastic. A patternmaker's lathe looks like a strong woodworking lathe. It often has a special part called a turret that helps cut straight lines very accurately.

These lathes can also turn very large pieces. Sometimes they have a sliding bed that moves away from the main part of the lathe, making space for big objects.

Metalworking Lathes

On a metalworking lathe, a hard cutting tool removes tiny bits of metal from the spinning object. This tool is usually held firmly in a tool-post or turret, which moves against the metal. Workers use handwheels or computer-controlled motors to move the tool. These cutting tools come in many shapes, like diamond, round, square, or triangular.

The tool-post moves with special screws called lead-screws. These screws can place the tool very precisely. The tool can be moved by hand or automatically to shape the metal. It can also cut threads or worm gears. Sometimes, a special liquid called cutting fluid is pumped onto the metal. This liquid cools the metal, helps the tool slide, and washes away metal shavings. Some metalworking lathes are controlled by a computer to make many parts quickly. These are called Computer Numerical Control (CNC) lathes.

Older or cheaper metalworking lathes need workers to change gears to cut different thread patterns. More modern lathes have a "quick-change box" that lets you pick common patterns with a lever. CNC lathes use computers to control all movements.

The metal piece can be held between two points called centres, or it can be clamped in a chuck. A chuck has movable jaws that grip the metal tightly.

Using a metalworking lathe can change the metal's properties a little. It can create tiny cracks, make the metal harder, or change how hard it is. You can find more details about metal and woodworking lathes at this website.

Cue Lathes

Cue lathes work like turning and spinning lathes. They are used to make billiard cues perfectly round and balanced. They can also fix cues that have worn down over time.

Glass-working Lathes

Glass-working lathes look similar to other lathes, but they work differently. They slowly spin a hollow glass object over a flame. The flame softens the glass, making it flexible. Then, workers can shape the glass by blowing air into it (called glassblowing) or by using heat-resistant tools. These lathes usually have two parts that hold the glass and spin it together. Air can be blown through one of the holders for glassblowing.

In diamond turning, a computer-controlled lathe uses a diamond-tipped tool to make very precise optical surfaces on glass or other materials. This is great for making complex aspheric lenses that are hard to make with regular methods. These lathes are super accurate, using air bearings and light measurements to place the tool perfectly. The finished glass usually needs a little more polishing to be perfectly smooth for a lens.

Metal-spinning Lathes

In metal spinning, a flat disk of sheet metal is held on the lathe. Workers use tools with smooth tips to press against the spinning metal. This pressure shapes the metal disk.

Metal-spinning lathes are quite simple, like woodworking lathes. To spin metal, you usually need a "mandrel," which is a wooden shape that acts as a template. For example, to make a sheet metal bowl, you need a solid wooden block shaped like the bowl.

Metal spinning is less common now because of faster industrial methods. However, it's still useful for making single items or small batches, where other methods would be too expensive.

Ornamental Turning Lathes

Ornamental turning lathes were developed in the 1800s. They were used to make beautiful, decorative items, not practical ones. By using special tools and attachments, these lathes can create incredibly complex shapes.

A special kind of ornamental lathe is the Rose engine lathe. It's used for "engine turning," often on precious metals like pocket-watch cases. These lathes have many accessories and complex ways to spin the material precisely. The cutting is usually done by spinning cutters, not by the spinning work itself. Because it's hard to polish these detailed items, soft materials like wood or ivory are often used. The best ornamental lathes are thought to be those made by Holtzapffel around the early 1800s.

Reducing Lathes

Many lathes can copy an item. The original item is put on one spinning part, and a blank piece of material is put on another. As both spin together, one part of an arm "reads" the original, and another part "carves" a copy.

A reduction lathe is a special lathe that can make a copy that is smaller than the original. It uses a system like a pantograph. So, if the "reading" part of the arm reads a detail that is one inch big, the cutting part might make that detail only a quarter of an inch big (a 4:1 reduction). Any reduction size is possible with the right setup.

Reducing lathes are used to make master dies for coins. A plaster model of the coin is copied and made smaller on the lathe to create the die used for minting.

Rotary Lathes

A rotary lathe spins a log of softwood (like spruce or pine) or hardwood (like birch) against a very sharp blade. The blade peels off a continuous sheet of wood. This was invented by Immanuel Nobel (father of the famous Alfred Nobel). The first such lathes in the United States appeared in the mid-1800s. The wood sheet produced is called wood veneer. It's used to make plywood and as a decorative surface on some types of chipboard.

Watchmaker's Lathes

Watchmaker's lathes are small but very precise metalworking lathes. They are usually used by horologists (people who study and make clocks and watches) to create tiny parts like balance staffs for watches. A hand-held tool called a graver is often used instead of a tool mounted on a slide. The first watchmaker's lathes were simple. The tiny part would be spun by a bow, often made of horsehair, wrapped around it. For more details, you can visit this website.

Recording Lathes

Recording lathes are used to make grooves on a surface to record sounds. These were used to create sound grooves on wax cylinders and later on flat recording discs. At first, the cutting lathes were moved by sound vibrations through a horn. Later, they were powered by electricity when microphones were used for recording. Many of these were professional machines, but some were made for home recording and were popular before home tape recorders came along.

Gallery

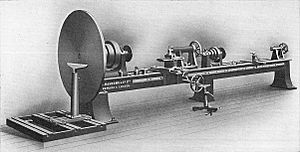

Examples of Lathes

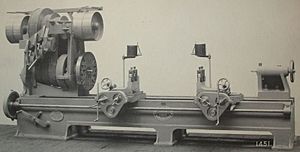

-

Belt-driven metalworking lathe at Hagley Museum

Examples of Work Produced from a Lathe

Images for kids

-

Chess pieces can be made using a lathe.

See also

In Spanish: Torno para niños

In Spanish: Torno para niños

| Valerie Thomas |

| Frederick McKinley Jones |

| George Edward Alcorn Jr. |

| Thomas Mensah |