Screw thread facts for kids

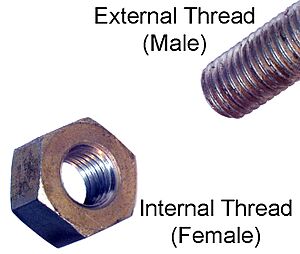

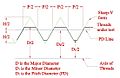

A screw thread is like a special ridge that wraps around a cylinder or cone in a spiral shape. Think of it like the grooves on a screw or a bolt! If the spiral is on a cylinder, it's called a straight thread. If it's on a cone, it's a tapered thread.

When you tighten a screw into a bolt, it's a bit like pushing a small wedge into a tight space. The screw and bolt surfaces press together very tightly. This creates a lot of friction, which holds them firmly in place.

Contents

How Screw Threads Work

Screw threads are one of the six simple machines. Simple machines help us do work more easily by giving us a mechanical advantage. This means they multiply the force we apply.

Screw Threads as Gears

In many machines, screw threads act like gears. They can change how movement happens. For example, in old steam engines, screw threads helped turn the power from steam into useful motion.

A great modern example is how a car engine works. The engine's pistons move up and down. Screw threads and gears in the car's transmission system help turn this up-and-down motion into the spinning motion of the car's wheels. The gears shown in the picture give you an idea of how this works.

Mechanical Advantage of a Screw

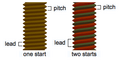

The mechanical advantage of a screw thread depends on its lead. The lead is the distance the screw moves forward in a straight line when you turn it one full circle. A screw with a smaller lead will move less distance with each turn, but it will be able to apply a much greater force. This is why it's easier to screw in a long, thin screw than a short, thick one, even if you're doing the same amount of work.

Uses of Screw Threads

Screw threads are used everywhere! They are in:

- Fasteners: Like screws, bolts, and nuts that hold things together.

- Machines: In car engines, bicycles, and many other devices to transfer power or change motion.

- Tools: In vices, clamps, and jacks to create strong gripping or lifting forces.

- Everyday items: From bottle caps to light bulbs, screw threads help things fit together and stay secure.

Images for kids

See also

In Spanish: Rosca (mecánica) para niños

In Spanish: Rosca (mecánica) para niños

| William M. Jackson |

| Juan E. Gilbert |

| Neil deGrasse Tyson |