Plywood facts for kids

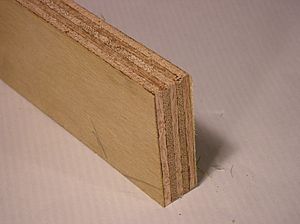

Plywood is a special type of wood material made by gluing together thin layers of wood, called "plies" or "veneers". Imagine stacking several sheets of paper, but instead of paper, it's thin wood! These layers are glued so that the wood grain of each layer goes in a different direction, usually at a 90-degree angle to the layer next to it. This makes plywood super strong and stable, much more so than a single piece of wood of the same thickness. It's part of a group of materials called "engineered wood," which also includes things like medium-density fibreboard (MDF) and oriented strand board (OSB).

The way the layers are glued with their grains going in different directions is called cross-graining. This clever trick has many benefits:

- It stops the wood from splitting easily when you nail into it.

- It helps the wood stay the same size, reducing how much it shrinks or expands with changes in temperature or moisture.

- It makes the plywood strong in all directions, not just one.

Usually, plywood has an odd number of layers (like 3, 5, or 7) so that it stays balanced and doesn't warp or twist. This design gives plywood great strength, especially when you try to bend it. Some high-quality plywood even has layers glued at 45-degree angles for extra strength in many directions.

The word ply comes from an old French word meaning "to fold."

Contents

History of Plywood

People have been gluing thin pieces of wood together for a very long time! The ancient Egyptians and Greeks used thin wood layers glued together. They did this because good wood was hard to find, and it also made the wood look nicer. They found out that this layered wood was also stronger and didn't bend as much, making it a great building material.

In 1797, a British naval engineer named Samuel Bentham thought of a way to make thin wood layers using machines. He also described how to glue these layers together to make a thicker, stronger piece, which is basically what we call plywood today.

About 50 years later, Immanuel Nobel (who was the father of Alfred Nobel, the inventor of dynamite!) realized that many thin layers of wood glued together would be stronger than one thick piece. He invented a special machine called a rotary lathe. This machine could peel a log into a continuous thin sheet of wood, like unrolling a giant paper towel.

By the 1860s, making plywood with rotary lathes was common in France. Plywood arrived in the United States around 1865. In 1928, the first standard-sized sheets of plywood (4 feet by 8 feet) were introduced in the U.S., becoming a popular building material.

Artists also started using plywood as a strong surface for their paintings instead of canvas. Special "artist boards" made of three-layer plywood were sold in New York as early as 1880. Later, around 1930, new types of strong, waterproof glues were developed, making plywood even more useful.

How Plywood is Made Strong

A typical sheet of plywood has nicer-looking wood layers on the outside (called "face veneers") and less perfect layers on the inside (called "core veneers"). The main job of these inside layers is to create space between the outer layers. This space helps the plywood resist bending, meaning thicker panels can cover larger areas without sagging.

When you bend plywood, the most stress happens on the very top and bottom layers. The middle layers experience almost no stress from bending. Different types of wood are used, giving plywood different weights and strengths. For example, birch plywood is quite dense and strong, while conifer (pine, spruce, fir) plywood is lighter.

Types of Plywood

There are many kinds of plywood, each made for different jobs:

Softwood Plywood

Softwood plywood is usually made from trees like cedar, Douglas fir, spruce, pine, or fir. It's often used for building houses and for industrial purposes.

Common sizes are 4 feet by 8 feet. The thickness of the layers can vary, and there's always an odd number of layers. Thinner plywood (like 5/8 inch thick) might be used for roofs, while thicker plywood (like 3/4 inch or more) is used for floors. Plywood for floors often has special edges called "tongue and groove" (T&G) that fit together like puzzle pieces. This makes the floor feel solid and prevents boards from moving up or down.

Hardwood Plywood

Hardwood plywood is made from strong trees like oak, beech, or mahogany. It's used for jobs that need extra strength and durability. Hardwood plywood is known for being very strong, stiff, and resistant to damage. It's great for heavy-duty floors, walls, and places where things might hit it. It also has a hard surface that resists scratches and wear.

Tropical Plywood

Tropical plywood is made from different kinds of hardwood trees found in tropical regions, especially in Asia, Africa, and South America. It's often stronger and more even in its layers than softwood plywood. Because of its high quality, it's often sold at a higher price. Many countries use tropical plywood for construction because it's strong and can be affordable. However, it's important that this wood is harvested responsibly to protect forests.

Aircraft Plywood

This is super strong and lightweight plywood, sometimes called "aircraft-grade" plywood. It's made from woods like mahogany, spruce, or birch, using special glues that can handle heat and moisture very well. It was used a lot during World War II to build parts of planes, like the famous British De Havilland Mosquito. This plane was nicknamed "The Wooden Wonder" because it used so much plywood, even for its wings and body!

Aircraft plywood is made to very strict standards. It can be as thin as 1/64 of an inch in total, but it's incredibly strong and light. Even the giant H-4 Hercules plane, built by Howard Hughes, was made using a special plywood-and-resin process.

Decorative (Overlaid) Plywood

This type of plywood has a beautiful outer layer made from fancy hardwoods like ash, oak, maple, mahogany, or teak. It's used when you want the look of real wood but with the strength and stability of plywood.

Flexible Plywood

Flexible plywood, sometimes called "wiggle board" or "bendy board," is designed to be bent into curved shapes. It's often used for making curved furniture or other designs. It's usually thin (about 3/8 inch thick) and has a very thin middle layer, allowing it to bend easily. People often glue two layers of flexible plywood together once it's shaped to make it stiff and hold its curve. Sometimes, a decorative wood layer is added on top.

Marine Plywood

Marine plywood is made to last a long time in wet and humid conditions, even underwater! It uses very durable wood layers with few flaws, and a special waterproof glue that resists water and fungus. This means it won't fall apart or get moldy when exposed to moisture for long periods. It's often used for building boats or other things that will be around a lot of water. There are special standards, like BS 1088, that ensure marine plywood is truly waterproof and durable.

Other Types of Plywood

There are many other specialized plywoods, including:

- Fire-retardant plywood: Treated with chemicals to make it harder to burn.

- Moisture-resistant plywood: Designed to handle damp conditions.

- Wire mesh plywood: Has a textured surface for better grip.

- Sign-grade plywood: Made to be smooth and easy to paint for signs.

- Pressure-treated plywood: Treated to resist rot and insects.

Baltic Birch plywood is a special type from around the Baltic Sea. It's very stable and has many layers of birch wood with no gaps inside, making it popular for cabinets and furniture.

How Plywood is Made

Making plywood starts with a good, straight log, often called a "peeler." This log is placed horizontally in a machine and spun around. A long, sharp blade then presses into the spinning log, peeling off a thin, continuous sheet of wood, much like unrolling a giant roll of paper. This thin sheet is the "veneer."

After peeling, the veneers are cut to the right size and dried. Then, any small holes or defects are fixed. Next, the veneers are glued together with their grains going in different directions. Finally, these glued layers are put into a large press where they are heated to at least 140°C (284°F) and pressed with great force. This heat and pressure bond the layers together to form a strong plywood panel.

For plywood used indoors, a glue called urea-formaldehyde is often used. It's less expensive but doesn't handle water well. For outdoor or marine plywood, stronger, water-resistant glues like phenol-formaldehyde are used to prevent the layers from separating when wet.

In the past, some glues used in plywood contained chemicals that could be a concern in very high amounts. But today, many manufacturers use glues that release very little or no formaldehyde, making them much safer. There are also many certifications, like Forest Stewardship Council (FSC), that ensure the wood comes from responsibly managed forests and that the production methods are environmentally friendly.

Plywood Sizes

Plywood comes in many thicknesses, usually from about 1/8 inch to 3 inches. The most common size for a sheet of plywood is 4 feet by 8 feet (1220 x 2440 mm). This size was first used for the 1905 Portland World Fair. Another common size in Europe is 5 feet by 5 feet, often used for Baltic birch plywood.

Specialized plywood for things like concrete forms can have different thicknesses and sizes. Aircraft plywood can be very thin, sometimes as thin as 1/8 inch total, but it's made with extremely thin layers (like 0.5 mm or even 0.1 mm thick) to make it incredibly strong and light.

Uses of Plywood

Plywood is used in countless ways because it's strong, stable, and resists cracking, shrinking, and warping.

Plywood made with outdoor glue can be used outside, but it works best when it doesn't stay soaking wet all the time. It also performs well in very cold temperatures.

Plywood is often used in engineering for things that need a strong, lightweight skin. It was very important in World War II for building planes and boats, like the British de Havilland Mosquito bomber and the American PT boats.

Plywood is also great for making curved shapes because it can bend easily along its grain. Skateboard ramps often use plywood as the smooth top surface over curved frames to create shapes like ocean waves.

Softwood Plywood Uses

Softwood plywood is commonly used for:

- Floors, walls, and roofs in homes.

- Panels that help buildings resist wind.

- Inside parts of vehicles.

- Making packages and boxes.

- Fences.

Some softwood plywood is coated so you can't see the wood grain. This is used for things like:

- Forms for pouring concrete.

- Surfaces that are ready to be painted in buildings.

Hardwood Plywood Uses

Hardwood plywood, especially with a special film coating, is often used for:

- Panels in concrete forms.

- Floors, walls, and roofs in trucks and other vehicles.

- Floors in shipping containers.

- Floors in buildings and factories that get a lot of foot traffic.

- Scaffolding materials (the temporary structures used by builders).

Birch plywood is used for special strong structures like:

- Blades for wind turbines.

- Insulation boxes for ships that carry liquefied natural gas (LNG).

Because it has a smooth surface and exact thickness, birch plywood is also popular for:

- High-quality loud speakers.

- Playground equipment.

- Furniture.

- Signs for outdoor advertising.

- Musical instruments.

- Sports equipment.

Tropical Plywood Uses

Tropical plywood, mostly from Southeast Asia, is used for:

- General construction.

- Concrete panels.

- Floor bases.

- Structural panels.

- Container flooring.

|

See also

In Spanish: Contrachapado para niños

In Spanish: Contrachapado para niños

| Emma Amos |

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |