Helmshore Mills Textile Museum facts for kids

Helmshore Mills Textile Museum

|

|

| Alternative names | Higher Mill, Whitakerś Mill |

|---|---|

| Architectural style | Stone built 3 storey |

| Structural system | Stone |

| Location | Helmshore, Rossendale, Lancashire, England |

| Owner | William Turner |

| Further ownership |

|

| Current owners | Lancashire Museums |

| Coordinates | 53°41′20″N 2°20′10″W / 53.6890°N 2.3362°W |

| Construction | |

| Built | 1789 |

| Floor count | 3 |

| Water Power | |

| Wheels | 2 Pitch back |

| Equipment | |

| Cotton count | 20 |

| Mule Frames | 4 per floor, Taylor Lang, Stalybridge |

| Doublers | 1 |

The Helmshore Mills are two old factories located by the River Ogden in Helmshore, Lancashire, England. They are called Higher Mill and Whitaker's Mill. Higher Mill was built in 1796 by William Turner. Whitaker's Mill was built later, in the 1820s, by the same Turner family.

These mills first worked with wool and then with cotton. By the 1920s, they were using a special process to spin recycled fabric called shoddy. The machines from that time have been kept and still work! The mills stopped operating in 1967. After that, a group called the Higher Mills Trust took them over. They turned the mills into a museum.

People say these mills are some of the best-preserved examples of cotton spinning and woollen fulling factories in the country that still work. The museum closed to the public for a while in 2016. However, it reopened in April 2018 for three days a week during the warmer months. Since November 2022, it also has a community café open on Thursdays in winter.

Contents

Where are the Helmshore Mills?

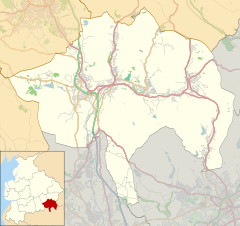

Helmshore Mills are in Helmshore, a village in the Rossendale Valley in Lancashire. The village is about 2 miles (3.2 km) south of Haslingden. It's also about 16 miles (25.7 km) north of Manchester.

Helmshore is built around the River Ogden, which is a smaller river that flows into the River Irwell. The village grew because of the seven cotton and wool mills that were built there.

The Story of the Mills

The Turner family was already involved in making textiles before these mills were built. In February 1789, they bought land to build a mill. They built Higher Mill as a woollen fulling mill. Fulling is a process that makes wool fabric thicker and stronger.

Later, in the 1820s, William Turner (who was part of the family) built a larger mill for preparing and spinning wool. The wool would then go to another mill for weaving. After weaving, it came back to Higher Mill for fulling and finishing. In 1857, this mill was destroyed by a fire. It was rebuilt in 1860 by Edward Turner.

After the American Civil War ended, cotton started coming back to Lancashire. The rebuilt mill then began spinning cotton. It had machines for processing raw cotton into fine cotton yarn.

In the 1920s, a company called L.Whitaker & Sons bought the mill. They put in machines to process recycled cotton. The mill continued this work until 1978. Higher Mill was run by Lawrence Whittaker from 1875. His family continued to use it as a fulling mill until 1967.

Becoming a Museum

When Rossall Whittaker passed away in 1971, Higher Mill was saved by people who cared about its history. They made it an Ancient monument to protect it. A trust bought the mill. A company called Platt Brothers, which also had a site in Helmshore, owned many old textile machines. They agreed to move these machines to Higher Mill.

Running a museum and keeping the old buildings in good shape was a big job for the trust. So, in 1975, Lancashire County Council stepped in to help. They took over the museum for 99 years. Whitaker's Mill became empty in 1978. The council saw how useful it would be to control both mills, so they bought Whitaker's Mill too. This allowed them to buy the Platt collection of machines in 1985. This created a complete museum about the textile industry in Lancashire.

What You Can See at the Museum

The museum shows three main parts of textile making: the wool story, the cotton story, and the spinning floor.

The wool story shows how wool was processed. You can see the water wheel that powered the machines. There are also fulling stocks, which were used to make wool thicker. You can also see a tenter frame. This frame had hooks called tenterhooks to dry cloth without it shrinking. You can also see how teasels were used to make the fabric soft and fluffy.

The cotton story shows what a hand weaver's cottage looked like. There's a frame loom with a hand-thrown shuttle. You can see models of a weaver and two women spinning yarn on different types of wheels. A child is shown doing hand-carding, which prepares the cotton fibers. There's an old spinning jenny from around 1760, which could spin 16 threads at once. You can also see an original Arkwright's first carding machine.

The museum has a full set of machines that processed cotton. These machines took cotton from bales and turned it into yarn. This includes an opener, scutcher, breaker card, finisher card, draw frame, and a complete water frame from 1790. In Whitaker's Mill, you can also see machines that prepared waste cotton for spinning.

The spinning floor is one of the most special parts of the museum. It has all the machines needed to prepare recycled cotton (shoddy) and turn it into rovings. These rovings then go onto large spinning mules. These mules, made by Taylor, Lang & Co, have 714 spindles! This spinning floor is the only original and complete one of its kind left.

The spun yarn from Helmshore Mills is sometimes sent to another museum, Queen Street Mill, to be woven into cloth.

Museum Closure and Reopening

In November 2015, Lancashire County Council announced they would stop funding five of their museums, including Helmshore Mills Textile Museum. This was due to financial challenges. The museums were initially set to close in March 2016, but this was delayed until September 30, 2016.

The museum did close on September 30, 2016, except for school groups who had booked visits. However, in April 2018, the council announced that the museum would reopen to the public. It now opens on Fridays, Saturdays, and Sundays from 12:00 PM to 4:00 PM during the summer season (from late March to early November). Since November 2022, the museum also has a Community Café open every Thursday from 11:00 AM to 4:00 PM during the winter.

The Mills as Historic Buildings

The entire Helmshore Mills site is a Scheduled Ancient Monument. This means it's a very important historical site that is protected. Higher Mill is also a Grade II listed building. This means it's a building of special architectural or historic interest. The tall chimney stack across the road is also a separately listed building.

How Condenser Spinning Worked

Fine spinning of cotton created a lot of waste material. This waste was then recycled in a condenser spinning mill. The waste came in different forms, like loose fibers or rejected spun threads. All of it had to be broken down into fibers again. Then it was prepared and carded, similar to new cotton. Because the fibers were very short, the process was slightly different. A machine called a Derby Doubler was used to mix the fibers. A special feature of the spinning mule used here was that the fibers were on a large beam instead of individual bobbins.

Boilers and the Tall Chimney

When a steam engine was put into Whitaker Mill, large boilers were common. To make the steam engine work best, air needed to be pulled over the burning coal. This was the job of the tall mill chimney. Since the mills are in a valley, the wind wasn't always strong enough. So, the chimney was built on a hill across the river. The smoke and hot air traveled through a special tunnel under the river to reach the chimney. This created a strong upward pull of air.

The first boilers in Whitaker Mill were installed around 1855. Later boilers were removed in the 1950s. Higher Mill had a different type of boiler for heating.

Water Power at the Mills

Clean water was very important for processing the cloth. This water was collected from field drainage on the hillside. It was stored in a special pond called a mill pond on the other side of the river. When needed, the water was piped across to the mill.

The water wheel, and later the steam engine's condenser, could use the river water, even though it was often polluted. A small dam, called a weir, was built about 800 meters upstream. This diverted water into a long, canal-like channel that led to the mill. After the water passed over the water wheel, it flowed through an underground channel called a goit back into the River Ogden.

See also

- List of mills in Lancashire

- Listed buildings in Haslingden

- Cotton mill