Carding facts for kids

Carding is a special process that gets natural fibers ready to be spun into yarn or made into fabric. Imagine tangled hair; carding is like combing it out! It untangles, cleans, and mixes fibers together. This creates a long, soft rope of fibers called a sliver. This sliver is then ready for the next steps in making textiles.

This process works by passing fibers between two surfaces that move differently. These surfaces are covered with "card clothing," which is a strong material with tiny metal pins. These pins break up any clumps of fiber and make the individual fibers lie neatly side by side. When preparing wool, carding happens after the wool has been teased (loosened).

The word "carding" comes from the Latin word Carduus, which means thistle. This is because dried thistles were first used to comb raw wool before machines were invented!

Contents

What is Carding?

Once fibers are neatly lined up, they can be used for many different things. This includes making cotton, soft batting for quilts, felt, or different types of yarn like woollen or worsted yarn.

Carding is also great for mixing different types of fibers or different colours together. When you blend fibers, the carding machine makes sure they are mixed evenly. Big machines used in factories also have parts that help remove small bits of plants or dirt from the wool.

A key part of all carding machines is the "card clothing." This is a strong, flexible material with many tiny wire pins stuck into it. The size, shape, and spacing of these pins are carefully chosen for what the carding machine will be used for. Later, in the 1800s, a new type of card clothing was invented for large machines. It used a single piece of serrated (saw-toothed) wire wrapped around a roller. This was called "metallic card clothing."

Carding machines are simply called "cards." You can even card fibers by hand if you are spinning yarn at home!

How Carding Machines Developed

Historians believe that tools using a bow (like a musical bow) to loosen fibers were first invented in India around the 2nd century CE. These tools, called kaman or dhunaki, would vibrate a string to fluff up the fibers.

In England, around the 1700s, people used pairs of hand cards to prepare wool. It was a two-step process: first, they "worked" the wool by rubbing the cards against each other, and then they "stripped" it by pulling the cards parallel.

In 1748, Lewis Paul from England invented two early carding machines. One used wires on a flat table, but it didn't work well. His second idea involved wires wrapped around a cylinder. Another inventor, Daniel Bourn, got a similar patent that same year. Later, Richard Arkwright and Samuel Crompton improved these inventions. Arkwright's patent for his carding machine was later cancelled because it wasn't seen as original enough.

By the 1780s, carding machines were being used in factories in England and Wales. Cotton was the main focus, but wool was also being carded in Yorkshire by 1780. For wool, two carding machines were often used: the first, called a "scribbler," opened and mixed the fibers. The second, called a "condenser," mixed them again and formed the web. The first factory in Wales to use these machines was in Dolobran in 1789. These early carding mills helped the Welsh flannel industry grow.

In 1834, James Walton invented the first practical machines that used wire cards. He also patented a new type of card clothing made with layers of cloth and rubber. These inventions became the standard for the carding industry.

By 1838, the Spen Valley in England had at least 11 factories making card clothing. By 1893, it was known as the "card cloth capital of the world." Today, only two companies making card clothing remain in England.

In the 1780s, a man named Baird brought carding technology from Scotland to Leicester, Massachusetts, in the United States. By the 1890s, this town made one-third of all hand and machine cards in North America.

Early carding mills in the 1780s were powered by water wheels. Modern machines are powered by electric motors.

How Cotton is Processed

| Bale breaker | Blowing room | |||||

| Willowing | ||||||

| Breaker scutcher | Batting | |||||

| Finishing scutcher | Lapping | Teasing | ||||

| Carding | Carding room | |||||

| Sliver lap | ||||||

| Combing | ||||||

| Drawing | ||||||

| Slubbing | ||||||

| Intermediate | ||||||

| Roving | Fine roving | |||||

| Mule spinning | Ring spinning | Spinning | ||||

| Reeling | Doubling | |||||

| Winding | Bundling | Bleaching | ||||

| Weaving shed | Winding | |||||

| Beaming | Cabling | |||||

| Warping | Gassing | |||||

| Sizing/slashing/dressing | Spooling | |||||

| Weaving | ||||||

| Cloth | Yarn (cheese) Bundle | Sewing thread | ||||

Carding is where the fibers are separated and then gathered into a loose strand called a sliver.

Here's how cotton processing works:

- Cotton arrives at the carding machine in large, flat rolls.

- The carding machines line up the fibers neatly, making them easier to spin.

- A carding machine has one large roller surrounded by smaller ones. All these rollers have small teeth. As the cotton moves through, the teeth get finer (closer together).

- The cotton leaves the carding machine as a "sliver," which looks like a thick rope of fibers.

In a broader sense, carding can include four steps: willowing, lapping, carding, and drawing.

- In willowing, the fibers are loosened.

- In lapping, dust is removed, creating a flat sheet of fibers.

- Carding itself is the combing of this tangled sheet into a thick rope or sliver.

- After carding, the sliver can be combed to remove shorter fibers, which makes a stronger yarn.

In the drawing step, a machine called a drawing frame combines several slivers into one. Doing this many times makes the sliver better quality, which helps create finer yarn. Since each sliver might have thin and thick spots, combining them makes the final rope of fibers more even.

For machine spinning, a "roving" is a thin strand of fibers, about the width of a pencil. These rovings are collected and then go to a slubbing frame. This machine adds a slight twist and winds the roving onto bobbins. Intermediate Frames and roving frames continue to make the thread finer, add more twist, and make it more even before winding it onto smaller tubes.

The carding machines used in wool mills today are often very similar to those used 20 to 50 years ago. Some are even from that time!

Carding machines can be small enough to fit on a kitchen table or large enough to fill an entire room. Larger machines work similarly but have many more drums. The fiber goes through these drums, getting finer as it moves along.

When the fiber comes off the drum, it's a flat, neat mass called a "bat." If you're using a small drum carder, this bat might be the finished product. But a large drum carder will turn that bat into a "roving" by stretching it thinner and thinner until it's the right thickness (often as thick as a wrist).

Some people who spin yarn by hand have small drum carders at home. They use them to mix different colored fibers that they bought already carded.

- Historical Carding Machines

-

A restored carding machine at Quarry Bank Mill in the UK.

Tools for Carding

Before machines, people wove fabric by hand at home. They used the same steps but on a smaller scale. These traditional skills are still used today by artists and hobbyists.

Hand Carders

Hand cards are usually square or rectangular paddles. They come in different sizes, from about 2x2 inches to 4x8 inches. The part of the paddle that does the work can be flat or curved and is covered with card cloth. Small cards, called flick cards, are used to fluff up the ends of a fiber lock or pull out a few strands for spinning.

You use a pair of hand cards to brush wool between them until the fibers are mostly lined up in the same direction. The aligned fiber is then gently peeled off the card to form a rolag. Carding can be a bit messy, so it's often done outside or over a cloth, depending on how clean the wool is.

The finished product from carding (rovings, rolags, and batts) is then ready for spinning into yarn.

Wool can be carded "in the grease" or not. "In the grease" means the natural lanolin (a waxy substance) that comes with the wool has not been washed out, making the wool feel a bit greasy. Large drum carders don't work well with lanolin, so most factories wash the wool before carding. However, hand carders (and some small drum carders) can be used to card wool that still has its lanolin.

Drum Carders

The simplest machine carder is the drum carder. Most drum carders are turned by hand, but some have an electric motor. These machines usually have two rollers, or drums, covered with card clothing. The smaller roller (called the licker-in) feeds fiber from a tray onto the larger storage drum. The two rollers are connected so they turn at different speeds. This makes the storage drum gently pull fibers from the licker-in. This pulling straightens the fibers and lays them onto the pins of the storage drum's card cloth. You keep adding fiber until the storage drum is full. A small gap in the card cloth makes it easy to remove the finished "bat" of fiber when the drum is full.

Some drum carders have a soft brush that presses the fiber into the storage drum. This helps to pack the fibers more tightly and straighten them a little more.

Cottage Carders

- How a Cottage Carder Works

-

Using a cottage carder to prepare white alpaca fiber.

Cottage carding machines are quite different from simple drum carders. These machines don't store fiber on their card cloth. Instead, fiber passes through the machine to be stored or sent to other machines for more processing.

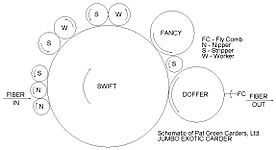

A typical cottage carder has one large drum (the swift) and several other rollers: two in-feed rollers (nippers), one or more pairs of worker and stripper rollers, a fancy, and a doffer. Fiber is usually fed into the machine by hand or a conveyor belt. The finished fiber from a cottage carder is often stored as a "batt" or made into "roving" and wound into bumps.

Raw fiber is placed on the in-feed table and moved to the nippers. The nippers hold the fiber and feed it onto the swift. As the fibers are transferred to the swift, many of them are straightened and laid onto the swift's card cloth. These fibers are then carried past the worker and stripper rollers to the fancy.

As the swift carries the fibers forward, any fibers that aren't straight yet are picked up by a worker roller. The worker roller turns very slowly compared to the swift, which helps to reverse the fiber. The stripper roller, which turns faster than the worker, pulls fibers from the worker and passes them back to the swift. The stripper's speed is slower than the swift's, so the swift pulls the fibers from the stripper for more straightening.

Straightened fibers are carried by the swift to the fancy roller. The fancy's card cloth is designed to connect with the swift's card cloth, lifting the fibers to the tips of the swift's pins. The swift then carries these fibers to the doffer. The fancy and the swift are the only rollers in the carding process that actually touch each other.

The slowly turning doffer removes the fibers from the swift. A "fly comb" then strips the fibers from the doffer. A thin, neat web of mostly parallel fibers, as wide as the carder's rollers, comes out of the machine. This web is then stored or sent for more processing.

See also

- Cotton mill

- Cotton-spinning machinery

- Doubling (textiles)

- DREF friction spinning

- Gig-mill

- Open end spinning

- Spinning

- Spinning wheel

- Textile manufacture during the Industrial Revolution

- Textile manufacturing

- Timeline of clothing and textiles technology

- Yarn realisation

| Tommie Smith |

| Simone Manuel |

| Shani Davis |

| Simone Biles |

| Alice Coachman |