Cotton-spinning machinery facts for kids

Cotton-spinning machinery refers to the machines that turn prepared cotton fibers into useful yarn or thread. These machines have been around for hundreds of years. During the 1700s and 1800s, as part of the Industrial Revolution, new cotton-spinning machines were invented. They helped make cotton products much faster, leading to mass production. These machines were set up in big factories called cotton mills.

| Bale breaker | Blowing room | |||||

| Willowing | ||||||

| Breaker scutcher | Batting | |||||

| Finishing scutcher | Lapping | Teasing | ||||

| Carding | Carding room | |||||

| Sliver lap | ||||||

| Combing | ||||||

| Drawing | ||||||

| Slubbing | ||||||

| Intermediate | ||||||

| Roving | Fine roving | |||||

| Mule spinning | Ring spinning | Spinning | ||||

| Reeling | Doubling | |||||

| Winding | Bundling | Bleaching | ||||

| Weaving shed | Winding | |||||

| Beaming | Cabling | |||||

| Warping | Gassing | |||||

| Sizing/slashing/dressing | Spooling | |||||

| Weaving | ||||||

| Cloth | Yarn (cheese) Bundle | Sewing thread | ||||

Contents

How Cotton Spinning Machines Changed History

The Spinning Wheel

The spinning wheel was first invented in the Islamic world around 1030 AD. It then traveled to China by 1090 and reached Europe and India by the 1200s.

Before the 1740s, people spun all cotton by hand using a spinning wheel. In England, a popular type was the Jersey wheel. Another kind, the Saxony wheel, used a foot pedal and spun thread very quickly.

Paul and Wyatt's Roller Machine

In 1738, two inventors named Lewis Paul and John Wyatt from Birmingham got a patent for their Roller Spinning machine. This machine used two sets of rollers that spun at different speeds. This helped stretch the cotton to an even thickness.

This idea was later used by Richard Arkwright for his water frame. Paul and Wyatt opened a mill in Birmingham in 1742, but it didn't make money. They tried again in Northampton in 1743, with 50 spindles. This factory worked until 1764.

Lewis Paul also invented a hand-driven carding machine in 1748. Carding helps untangle and clean cotton fibers. His invention was later improved by Richard Arkwright and Samuel Crompton.

The Spinning Jenny

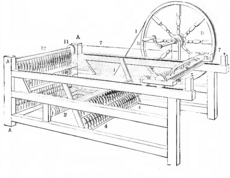

The spinning jenny was a special spinning wheel that could spin many threads at once. It was invented around 1764. Many people believe James Hargreaves from Lancashire, England, invented it. The spinning jenny was a big step up from the single-spool spinning wheel.

The Water Frame

Richard Arkwright developed and patented the Water frame in the 1770s. This machine stretched the cotton fibers using rollers and then twisted them onto a spindle. It was a large, heavy machine that needed power to run. In the late 1700s, this power came from water wheels.

Because of this, cotton mills were built next to rivers, like the River Derwent in Derbyshire. The water frame could only spin thread in one direction.

The Spinning Mule

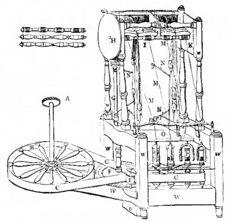

The spinning mule was created in 1779 by Samuel Crompton. It combined the best parts of Arkwright's water frame and Hargreaves' spinning jenny. It was called a "mule" because it was a mix of two different machines.

The mule worked in steps: it would pull out the cotton fibers, twist them, and then wind the new thread onto a spindle. Another machine, the throstle frame, worked continuously. The spinning mule became fully automatic in the 1830s.

The mule was the most common spinning machine from 1790 until about 1900. Some mills still used it for very fine yarns until the 1960s. A cotton mill in 1890 might have had over 60 mules, each with more than 1,300 spindles!

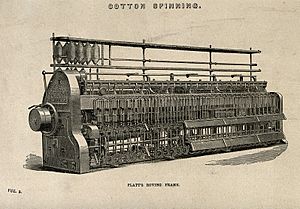

Between 1824 and 1830, Richard Roberts invented parts that made the mule completely self-acting. The Platt Brothers from Oldham, England, were famous for making these machines.

The Throstle Frame

The Throstle frame was an improved version of the water frame. It used the same ideas but was built better and powered by steam engines. In 1828, the Danforth throstle frame was invented in the United States. It was named "throstle" because the sound it made while running was like the song of a thrush bird.

The Ring Frame

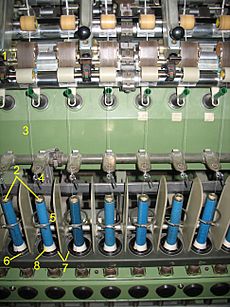

The Ring frame was invented by John Thorp in Rhode Island around 1828. It was further developed by Mr. Jencks. This machine is still used today in modern textile factories.

Other Spinning Methods

Newer methods like "break or open-end spinning" and "DREF friction spinning" have also been developed. These methods offer different ways to spin cotton yarn even faster and more efficiently.

What Happens Next?

After the cotton is spun into single threads by machines like the ring frame or mule, it's often ready to be used. However, if the thread needs to be extra strong or smooth, like for sewing, crocheting, or making carpets, two or more single threads are twisted together. This process is called "doubling." Doubling can also create special effects, like multi-colored or bumpy yarns.

See also

- Cotton mill

- Textile manufacture during the Industrial Revolution

- Textile manufacturing

- Timeline of clothing and textiles technology

Images for kids

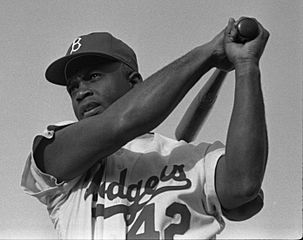

| Jackie Robinson |

| Jack Johnson |

| Althea Gibson |

| Arthur Ashe |

| Muhammad Ali |