Bancroft Shed facts for kids

Bancroft engine house and chimney

|

|

| Cotton | |

|---|---|

| Weaving shed | |

| Architectural style | Single storey |

| Owner | James Nutter & Sons Ltd |

| Current owners | Bancroft Mill Engine Trust |

| Coordinates | 53°54′40″N 2°11′31″W / 53.9111°N 2.1919°W |

| Construction | |

| Built | 1914 |

| Completed | 1920 |

| Demolished | 1979 |

| Floor count | 2 storey warehouse, 1 storey shed |

| Floor area | 200 feet (61 m) x 250 feet (76 m) |

| Design team | |

| Architecture Firm | W M Atkinson of Colne |

| Power | |

| Date | 1920 |

| Engine maker | William Roberts of Nelson |

| Engine type | Cross compound |

| Valve Gear | Corliss valves operated by Dobson trip gear |

| rpm | 69 |

| Transmission type | Rope drive to second motion, then line shaft |

| Boiler configuration | |

| Boilers |

|

| Pressure | 160 |

| Equipment | |

| Date | 1920 |

| Manufacturer | Various |

| No. of looms | 1200 |

Bancroft Shed was a special building called a weaving shed in Barnoldswick, England. It was a place where cotton was turned into cloth using many machines called looms. Building the shed started in 1914, but it was finished in 1920.

The mill closed its doors on December 22, 1978, and was later taken down. However, the engine house, tall chimneys, and boilers were saved. Today, they are a working steam museum. This mill was unique because it was the last steam-powered weaving shed ever built and the last one to close. You can visit the engine house and see the powerful William Roberts steam engine run. It uses steam made from donated wood.

Contents

Where Was Bancroft Shed?

Bancroft Shed was the very last weaving shed built in Barnoldswick. This town once had twelve other weaving sheds. Barnoldswick is located between Burnley and Skipton. It is about 30 miles (48 km) north of Manchester. The town sits high up in the Pennine hills, about 600 feet (183 m) above sea level.

In 1920, Barnoldswick was an industrial town with 10,000 people. There were 24,000 looms working there! The town is on the edge of two important textile areas: the Yorkshire wool district and the Lancashire cotton weaving district.

History of the Mill

James Nutter, the owner, used a temporary space while his new mill was being built. W M Atkins designed Bancroft Shed in 1914. But construction stopped because of the Great War. The weaving shed was finally finished in 1920. The opening ceremony happened in March 1920.

About 50 Lancashire looms were put in. Weavers from another mill came to help set them up. In 1920, most weavers were paid for each piece of cloth they made. But setting up a new mill was tricky. So, workers were paid a regular wage at first. Six weeks later, when everything was running smoothly, they went back to being paid by the amount of cloth they produced.

Bancroft Shed opened in 1920, which meant it missed the really good years for textile mills. During the Great War, Britain lost many of its customers overseas. Only the most specialized weaving sheds managed to survive.

Working with More Looms

Mills tried to become more efficient. Weavers who usually worked four looms were encouraged to work six or more. This was called the "more looms system." It meant fewer weavers were needed. The looms were also slowed down a bit to make this system work.

In the 1940s, the mill needed more power. An extra Cornish boiler was added. By 1935, 450 people worked at Bancroft Shed. They ran 1,152 looms for 50 hours a week. They made about 200,000 yards (182,880 m) of plain cloth.

During World War II (1939–1945), many empty weaving sheds were taken over by the government. Companies like Rover and Rolls-Royce moved into Barnoldswick. The government also controlled the cotton industry. James Nutter had to close some of his other businesses. He moved looms into storage at Bancroft. This meant he had only 500 working looms. Even with these challenges, Nutters kept weaving throughout the war.

After the war, weavers wanted better working conditions. The "more looms system" became very common. Weavers at Bancroft started working eight looms, then even ten looms at a time.

In the 1950s, conditions improved. The mill's lighting was updated. Automatic machines were added to feed coal to the Lancashire boiler. The looms were rearranged into sets of ten. However, a row of eight looms was kept for older weavers.

By 1976, the mill was mostly doing special orders. Experienced weavers and managers saw that demand for cloth was decreasing. They started to leave. In September 1978, the mill announced it would close. It finally shut down on December 22, 1978. The demolition began the next year.

How the Mill Was Built

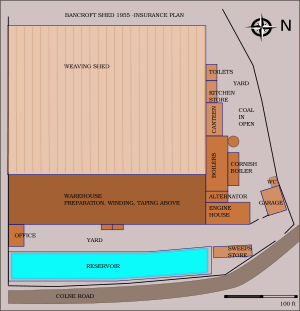

The mill had a two-story warehouse, a boiler room, and an engine shed. There was also a very large single-story weaving shed. When the mill closed in 1979, the warehouse and weaving shed were torn down.

A 120-foot (37 m) tall chimney stood to the west. To the south was a large lodge (a pond) that was 60 meters (200 ft) by 25 meters (82 ft). After the shed was demolished, the pond was filled in. The large Lancashire boiler is now kept full of water from the roof. This water is used for the engine's condenser and for the Cornish boiler.

The weaving shed was originally about 250 feet (76 m) by 200 feet (61 m). It was built into a hillside. It had special north-facing roof windows to let in natural light. This shed held 1200 looms. The boiler room and engine house were on the west side. The warehouse was to the south. The ground floor of the warehouse was for storage. The upper floor was for preparing the yarn.

Powering the Mill

Steam for the mill came from a Lancashire boiler. In 1947, a Cornish boiler was added for extra steam. But it was disconnected in 1948 because of problems. A special machine called an economiser preheated the water for the boiler. The boiler was first fed coal by hand. Later, an automatic machine was installed in the 1930s. Steam was heated to 160 pounds per square inch (psi).

When the mill closed in 1979, the Lancashire boiler needed repairs. The Cornish boiler, which had not been used for 30 years, was fixed up. It is now heated by donated wood. It makes steam at 50 psi to run the engine on special Heritage Steam Days. The mill had a 130-foot (40 m) chimney. This tall chimney helped create the right air flow for the boiler. The Bancroft chimney was repaired in 1997.

The Bancroft mill engine is a huge steam engine. It was built in 1914 and installed in 1920. It was made by William Roberts of Nelson. The engine's two main parts were even given names: "James" and "Mary Jane." Together, they could produce 600 horsepower. This was enough power for 1200 looms. The engine ran at 68 rotations per minute.

Engine and Boiler Gallery

How Weaving Equipment Worked

When yarn arrived at the mill, it was on different-sized bobbins. It needed to be wound onto smaller bobbins called pirns. These pirns fit into the shuttles used by the looms. In 1920, Bancroft Shed bought yarn already wound onto pirns. Later, in 1970, the mill started winding its own pirns.

The yarn was carried in two types of shuttles. The first type, called "kissing shuttles," caused health concerns. They were replaced by safer "self-threading shuttles."

To prepare the warp threads (the long threads in weaving), yarn was taken from 300 bobbins. It was then wound onto a large roller called a beam. Several beams were combined to make a very long beam with 2000 threads. This beam was then put into a sizing machine. The threads passed through a special mixture to make them stronger and smoother. This mixture was unique to each mill. The threads were then dried over hot cylinders and wound onto the "weavers beam."

The weavers beam was then taken to a drawing-in frame. Here, each thread was carefully passed through small loops called healds. Then, it went through a comb-like tool called a reed. This job was done by a "reacher-in" (often a young boy) and a "loomer." The reacher-in handed each thread to the loomer, who threaded it. The mill had two drawing-in frames.

Sometimes, if the loom had already made that type of cloth, a short length of warp thread was left on the healds and reed. A "twister" would tie the new threads to the old ones. This was much faster than starting from scratch. A special machine called a Barber-Colman knotter could do this job even faster, in about 20 minutes.

Once ready, the weavers beam went into the weaving shed. A weaver would operate four Lancashire Looms. These looms worked very fast. A "tackler" was in charge of keeping the looms running. They looked after about 130 looms. With the "More Looms system" after World War II, weavers operated ten looms. But the tackler's job became harder, so they looked after fewer looms, about 70.

Weaving Equipment Gallery

-

Bobbins for beaming frame (at Queen Street Mill, Burnley)

Learn More

- Cotton mill

- Helmshore Mills Textile Museum

- Queen Street Mill

- Textile manufacturing

- List of mills in Lancashire

| Delilah Pierce |

| Gordon Parks |

| Augusta Savage |

| Charles Ethan Porter |