Lithgow Blast Furnace facts for kids

Quick facts for kids Lithgow Blast Furnace |

|

|---|---|

The remains of the furnace, pictured in 2004.

|

|

| Location | Inch Street, Lithgow, City of Lithgow, New South Wales, Australia |

| Built | 1906–1907 |

| Owner | Lithgow City Council |

| Official name: Lithgow Blast Furnace; Eskbank Ironworks Blast Furnace site; Industrial Archaeological Site | |

| Type | State heritage (archaeological-terrestrial) |

| Designated | 2 April 1999 |

| Reference no. | 548 |

| Type | Furnace |

| Category | Mining and Mineral Processing |

| Builders | William Sandford Ltd. |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Lithgow Blast Furnace is a really old blast furnace that is now a cool park and visitor attraction in Lithgow, New South Wales, Australia. It was built between 1906 and 1907 by a company called William Sandford Limited. People also know it as the Eskbank Ironworks Blast Furnace site. Today, the Lithgow City Council owns it, and it was added to the New South Wales State Heritage Register in 1999 because it's so important.

Contents

History of Ironmaking in Lithgow

Early Days: 1875 to 1900

Lithgow has a long history with making iron and steel. The first iron was made here in October 1875. A man named Dan Williams found iron ore on land owned by Enoch Hughes. Hughes had worked at another iron factory before.

Hughes convinced James Rutherford, a famous businessman from Cobb & Co, to help start the Lithgow Valley Iron Works. Other important people involved were John Sutherland, a government minister, and Dan Williams, an engineer.

The first factory had a blast furnace, a foundry (where metal is melted and shaped), and two rolling mills (machines that flatten metal). They first made about 20,000 tonnes of 'pig iron' from local rocks. This iron was then turned into things like railway tracks and metal bars.

The first blast furnace at the Eskbank Ironworks closed in 1882. It's said that James Rutherford even blew it up so it couldn't be used again! After that, the rolling mills were used to reshape old iron rails into new bars.

In 1886, William Sandford leased the rolling mills. He later bought the ironworks in 1894.

William Sandford's New Furnace: 1901-1907

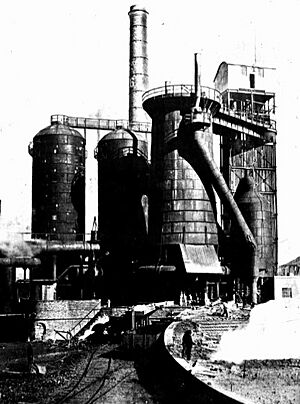

The Lithgow Blast Furnace we see today was built by William Sandford in 1906-1907. It was built to melt iron from ore. Many people confuse it with the earlier furnace that operated from 1875 to 1882.

Sandford's new furnace was built about 1 kilometre away from his coal mine. Some people thought this was a strange choice. However, it was close to the railway, which was good for moving materials, and it was big enough to grow in the future.

In 1901, William Sandford announced a big success: he had made the first usable steel in Australia at the Eskbank Ironworks! He believed that making iron and steel was very important for Australia.

To help his business, Sandford tried to get the government to support him. He even ran for election to try and change laws about trade. He also tried to convince the New South Wales government to take over his works.

Sandford won a big contract to supply steel and iron to the government. To do this, he needed to build a new blast furnace to make pig iron for the steel. He built it as promised.

The new Blast Furnace officially opened on May 13, 1907, with the Premier of New South Wales there. This was a very proud moment for Sandford, and he was called the "father of the Australian steel industry."

Even though he was successful, Sandford was having money problems. He couldn't get enough money to keep the business going. In December 1907, the bank took over the ironworks.

The Premier of New South Wales then asked the Hoskins brothers, Charles and George, to take over the Lithgow iron and steelworks. Sandford was very sad to leave Lithgow and felt let down.

Hoskins Brothers Take Over: 1908-1928

In 1908, the Hoskins brothers bought the company. They were already big in making iron pipes in Australia. They didn't change the main Blast Furnace much at first, but they made many changes to the rest of the ironworks.

The Hoskins brothers also got Sandford's government contract, which helped them succeed. Because of this success, they built 80 coke ovens and a second blast furnace in 1913. This second furnace was very similar to Sandford's first one, but a bit bigger.

The Hoskins brothers were very active in the iron industry. They were also very strong against workers forming unions. Charles Hoskins was known for being impatient, which sometimes caused problems with the workers.

When World War I started, the factory grew a lot. Even though another big steel company, BHP, opened a plant in Newcastle in 1915, the Lithgow works still did very well. A lot of their profits were used to make the steelworks even bigger. In 1923, a huge new engine was added to the original furnace. It weighed 400 tonnes and was the largest in Australia.

In the mid-1920s, the company decided to move its operations to Port Kembla. This was because Port Kembla had better natural resources and transport links. The Lithgow site was closed down in 1928, though the last workers left in 1932.

The Lithgow City Council bought the site, and it was opened to the public as The Lithgow Blast Furnace Park in 1988.

What You Can See at the Site

The Lithgow Blast Furnace site is on the edge of a natural ridge called Coal Stage Hill. The area has been changed a lot by the factory's construction and use. It's shaped a bit like a wedge.

The site is on three different levels:

- Top Level: This is where the main factory buildings were. It's about 200 metres long and 100 metres wide.

- Middle Level: This area has the old railway track that went to the steelworks.

- Bottom Level: This is the area between Inch Street and the upper levels. You can still see piles of slag (waste material from making iron) here.

You can still see the remains of different parts of the factory from its three main building periods:

- Phase 1 (1906-1907): You can find parts of the first furnace, its four stoves (used to heat air), the base of the chimney, and areas where raw materials were stored.

- Phase 2 (1908-1913): This includes parts of the second furnace and its stoves, another chimney base, and the railway bridge over Inch Street.

- Phase 3 (1914-1925): Here you can see foundations for later engines and machinery used to break up pig iron.

Some key things you can see or learn about at the site include:

- Engineers Australia Historic Engineering Marker: A special marker showing its importance in engineering history.

- Thompson Blowing Engine: This huge engine, installed in 1923, weighed 400 tonnes and blew a lot of air into the furnace.

- Parsons Turbines: Three other engines that blew air, installed as the furnace grew.

- Davy Engine House: This building held an air blower installed in 1906.

- Boiler House: This building had ten large boilers that used waste gases from the furnaces to make steam.

- Material Storage Bins: This area could hold 50,000 tonnes of iron ore, limestone, and coke.

- Blast Furnace No. 1: Built in 1907, it was 23 metres high and 5.8 metres wide.

- Blast Furnace No. 2: Built in 1913, it was very similar to No. 1, just a little bigger.

- Cowper Stoves: These stoves were filled with special bricks and used to heat the air before it went into the blast furnaces.

- Pig Beds: These were sand moulds where the hot, liquid iron from the furnace was poured to cool into 'pig iron' shapes.

- Cooling Pond: Built in 1907, this pond held water used to cool the furnace and for the boilers.

Condition of the Site

The site has a lot of archaeological potential. This means there are many hidden clues underground that can help us learn more about its history.

Changes Over Time

The construction of the site happened in three main stages:

- Phase 1 (1906-1907): William Sandford built the first blast furnace and its related plant.

- Phase 2 (1908-1913): G. and C. Hoskins Ltd. added to the existing plant and built the second blast furnace. They also built new railway lines and coke ovens.

- Phase 3 (1914-1925): G. and C. Hoskins Ltd. continued to improve the plant with new machinery and extensions.

Why the Site is Important

The Lithgow Blast Furnace site is very important because it shows how a major Australian industry grew and changed over time. It is the only remaining example of its kind.

- A Look into History: From 1906 to 1913, the Blast Furnace was the only place making iron in Australia. It was a huge producer for many years after that. It shows how Australia's iron and steel industry grew and how confident the country was becoming. These industries were also super important for New South Wales and especially for Lithgow.

- Beautiful and Functional Design: The Blast Furnace is nicely located outside the town, offering great views. Its design was practical and strong. It has a special, almost romantic feel and has been photographed many times. The slag dumps next to the site show the powerful forces used to make iron.

- A Symbol for the Community: The men who built and worked at the furnace faced tough conditions. They showed amazing strength, teamwork, skill, and pride in their work. The site is a symbol of their hard work and the fight for better conditions. It represents the strong "spirit of Lithgow."

- Learning from the Past: The remains of the site show how a big industrial factory grew and improved over time. It's a valuable place to study how ironmaking technology changed.

| Claudette Colvin |

| Myrlie Evers-Williams |

| Alberta Odell Jones |