Maglev train facts for kids

Maglev trains are a special type of train that uses powerful magnets to float above the track. The word "Maglev" comes from "magnetic levitation," which means floating using magnets.

These trains use two main sets of electromagnets. One set pushes the train up, lifting it about 10 cm (4 inches) off the track. The other set moves the floating train forward. Because the train doesn't touch the track, there is no friction, which allows it to go very fast.

Some maglev systems are designed for high speeds, traveling over 400 km/h (250 mph) between cities. Others are for slower, urban travel, moving at speeds between 80 and 200 km/h (50-125 mph). The Shanghai maglev train is currently the only high-speed maglev train used for regular travel.

Contents

How Maglev Trains Were Developed

The idea of using magnets to move things has been around for a long time. In the late 1940s, a British engineer named Eric Laithwaite started working on a special type of electric motor called a "linear induction motor." He was a professor at Imperial College London.

Laithwaite's work on linear motors was perfect for maglev systems. In the early 1970s, he found a new way to arrange magnets. This allowed a single set of magnets to both lift the train and push it forward. This made it easier to build maglev systems.

The first maglev system for public use opened in 1984 near Birmingham, England. It was called "MAGLEV" and connected Birmingham Airport to a nearby train station. It traveled on a 600-meter (about 2,000 feet) track at speeds up to 42 km/h (26 mph). However, this system closed in 1995 because it had many problems.

How Maglev Technology Works

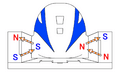

There are two main ways maglev trains use magnets to float and move:

- Electromagnetic Suspension (EMS): In this system, electromagnets on the train are attracted to a special metal track. This attraction pulls the train up and keeps it floating. Computers control these magnets very carefully to keep the train stable.

- Electrodynamic Suspension (EDS): This system uses very strong magnets, often "superconducting" magnets, on the train. As the train moves, these strong magnets create electric currents in the track. These currents then create their own magnetic fields, which push and pull the train, making it float above the track.

Maglev Trains vs. Regular High-Speed Trains

Maglev trains are different from regular trains because they don't have wheels touching the track. This means they don't have friction from wheels, bearings, or axles.

- Speed: Maglev trains can go faster than regular trains. While some experimental wheeled trains have reached similar speeds, regular trains wear out much faster at very high speeds because of friction. Maglev trains don't have this problem.

- Maintenance: Maglev trains need less maintenance for their tracks and the trains themselves. Regular trains have parts that wear out quickly due to friction and movement, like brakes and overhead wires. Maglev trains avoid these issues.

- Weather: Maglev trains are designed to work well in snow, ice, strong winds, and rain. However, most existing maglev systems are not in places with very harsh weather, so this benefit is still being tested.

- Acceleration: Maglev trains can speed up and slow down faster than regular trains. This is because they don't rely on friction with the track.

- Track: Maglev trains need their own special tracks. They cannot run on regular train tracks. This means building a maglev system can be very expensive because entirely new tracks must be built. However, some countries are thinking about building new tunnels and bridges for regular high-speed rail in a way that they could be upgraded for maglev in the future.

- Efficiency: At lower speeds, regular trains might be more efficient. But at high speeds, maglev trains can be more efficient because they have no rolling resistance. Their main challenges are air resistance and a type of magnetic drag.

- Noise: Maglev trains are generally quieter than regular trains at the same speeds. This is because their main noise comes from pushing air, not from wheels on rails.

- Control Systems: High-speed maglev systems are controlled by computers. Human operators cannot react fast enough for these speeds. This means there's no need for traditional signaling systems or train whistles.

Maglev Trains vs. Airplanes

Maglev trains can also be compared to airplanes for travel:

- Efficiency: Maglev systems can be very efficient over distance, sometimes even more efficient than airplanes. However, airplanes fly at high altitudes where the air is thinner, which reduces air resistance. This allows jets to be very efficient at high speeds. Maglev trains operate closer to the ground, where air is thicker.

- Routing: Maglev trains are good for journeys of about 800 km (500 miles) or less. They can also easily stop at places along the way.

- Availability: Maglev trains are less affected by bad weather than airplanes.

- Travel Time: With maglev trains, you don't have to go through long security checks like at airports. You also save time because there's no taxiing or waiting for take-off and landing.

Maglev trains are designed to be very stable and fast because they float. While some maglev systems use small wheels for support at very low speeds, they mostly rely on magnets. This can make them quieter and smoother than regular trains.

Why Maglev Trains Are Not Everywhere

Even with over 100 years of research, there are only a few maglev trains operating today. Most are in China, South Korea, and Japan. Building maglev systems can be very expensive.

However, maglev trains have some great benefits:

- They have lower operating and maintenance costs because parts don't wear out as quickly.

- They are much less likely to derail (go off the tracks).

- They offer a very quiet and smooth ride for passengers.

- They produce little to no air pollution.

- They can climb steeper hills (up to 10%) compared to regular trains (up to 4%). This means less need for tunnels or leveling the ground when building tracks.

Maglev Speed Records

The fastest speed ever recorded by a maglev train was 603 km/h (375 mph). This was achieved by Japan's L0 superconducting maglev train on April 21, 2015. This was faster than the speed record for a conventional wheeled train.

The L0 record was set on a 42.8 km (26.6 miles) test track. No maglev or wheeled train has ever operated commercially at speeds over 500 km/h (310 mph).

| Year | Country | Train | Speed | Notes |

|---|---|---|---|---|

| 1971 | West Germany | Prinzipfahrzeug | 90 kilometres per hour (56 mph) | |

| 1971 | West Germany | TR-02 | 164 kilometres per hour (102 mph) | |

| 1972 | Japan | ML100 | 60 kilometres per hour (37 mph) | with people on board |

| 1973 | West Germany | TR04 | 250 kilometres per hour (160 mph) | with people on board |

| 1975 | West Germany | Komet | 401 kilometres per hour (249 mph) | no people on board |

| 1978 | Japan | HSST-01 | 308 kilometres per hour (191 mph) | no people on board |

| 1979 | Japan | ML-500R | 504 kilometres per hour (313 mph) | (no people on board) First time over 500 km/h! |

| 1979 | Japan | ML-500R | 517 kilometres per hour (321 mph) | (no people on board) |

| 1987 | West Germany | TR-06 | 406 kilometres per hour (252 mph) | (with people on board) |

| 1987 | Japan | MLU001 | 401 kilometres per hour (249 mph) | (with people on board) |

| 1989 | West Germany | TR-07 | 436 kilometres per hour (271 mph) | (with people on board) |

| 1993 | Germany | TR-07 | 450 kilometres per hour (280 mph) | (with people on board) |

| 1997 | Japan | MLX01 | 531 kilometres per hour (330 mph) | (with people on board) |

| 1997 | Japan | MLX01 | 550 kilometres per hour (340 mph) | (no people on board) |

| 1999 | Japan | MLX01 | 552 kilometres per hour (343 mph) | (with people on board, five cars) |

| 2003 | Japan | MLX01 | 581 kilometres per hour (361 mph) | (with people on board, three cars) |

| 2015 | Japan | L0 | 590 kilometres per hour (370 mph) | (with people on board, seven cars) |

| 2015 | Japan | L0 | 603 kilometres per hour (375 mph) | (with people on board, seven cars) |

Interesting Facts About Maglev Trains

- The very first patent related to magnetic levitation for trains was given to Albert C. Albertson in 1902. It suggested using magnets to reduce the weight on the wheels, while still using regular engines.

- In 1912, a French-American inventor named Émile Bachelet showed off a model maglev train in New York.

- Even though building maglev tracks is expensive, the trains themselves can be cheaper to make and keep running because they have fewer moving parts that wear out.

Images for kids

-

Transrapid at the Emsland test facility in Germany.

See also

In Spanish: Tren de levitación magnética para niños

In Spanish: Tren de levitación magnética para niños