Mount Elliott Mining Complex facts for kids

Quick facts for kids Mount Elliott Mining Complex |

|

|---|---|

Ruins, 2008

|

|

| Location | Selwyn, Shire of Cloncurry, Queensland, Australia |

| Design period | 1900 - 1914 (early 20th century) |

| Built | 1908 |

| Architect | William Henry Corbould |

| Official name: Mount Elliott Mining Complex, Mount Elliott Smelter, Selwyn | |

| Type | archaeological (landscape, built) |

| Designated | 16 September 2011 |

| Reference no. | 700012 |

| Significant period | 1906 - 1953 |

| Significant components | machinery/plant/equipment - mining/mineral processing, embankment - tramway, kiln, smelter, boiler room/boiler house, building foundations/ruins, cemetery, garden - bed/s, slab/s - concrete, tank stand |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Mount Elliott Mining Complex is an old copper mine and smelter in Queensland, Australia. It's located near a place called Selwyn. This important historical site was designed by William Henry Corbould and built in 1908. It's also known as the Mount Elliott Smelter. Today, it's protected as a heritage site because of its history.

Contents

A Look Back: The History of Mount Elliott

The Mount Elliott Mining Complex shows us what copper mining and smelting were like in the early 1900s. It also includes the remains of the old town of Selwyn. Copper mining started here in 1906. Soon after, they began smelting, which is a process to get metal from ore.

Big improvements were made to the mine and smelter between 1909 and 1910. These changes were led by W.H. Corbould. After these upgrades, the town of Selwyn grew quickly. By 1918, about 1500 people lived there.

In the 1920s, the Mount Elliott Company became very big. It took over other mining companies in the area. Later, in 1943, Mount Isa Mines bought the Mount Elliott operations. This was to make sure there was enough copper during World War II. The Mount Elliott Company officially closed down in 1953.

The Mount Elliott Smelter Story

People knew about copper in the Cloncurry area since 1867. That's when Ernest Henry found the Great Australia Mine. In 1899, James Elliott found copper on a hill that became Mount Elliott. He sold his share to James Morphett, who then sold it to John Moffat, a famous mining leader.

Developing the Cloncurry area was hard. They needed a lot of money and easy ways to transport things. Without money, they couldn't find enough ore. Without enough ore, it was hard to build a railway. And without a railway, it was risky to invest money. Someone had to break this cycle!

In 1906–1907, copper prices were very high. This helped the Cloncurry area grow. The Great Northern railway was extended west in 1905–1906. Mines like Mount Elliott started selling shares to investors. A mining shaft was dug, and equipment was set up in 1906.

Mount Elliott Limited was formed in 1906. Later, British and French investors took over. They teamed up with another company to build a railway. This railway would connect Cloncurry to Mount Elliott (Selwyn). The railway construction finished in December 1910. It ended right at the Mount Elliott smelter.

By 1907, the main mine shaft was ready. They started building the smelters using some used equipment. At this time, W.H. Corbould became the general manager.

The used equipment started working in May 1909, but it caused many problems. Corbould called it the "worst collection of worn-out junk." He convinced the company to get rid of it and let him design new equipment.

Corbould was very smart. He knew a lot about metals and rocks. He realized they needed to control many mines to get a steady supply of ore. He also found a way to smelt low-quality ore more cheaply. He did this by mixing different types of ore. He also made the smelter bigger and wanted all smelting in the area to work together. In 1912, Corbould bought other mines for Mount Elliott Limited.

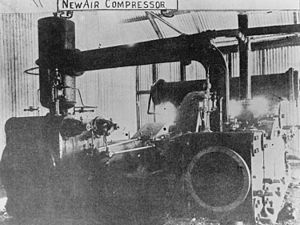

A company called Walkers Limited built a new furnace for the smelters. They also built an air compressor and a blower. An electric motor provided power for cranes and lights.

The new smelter started working in September 1910. It worked very well, producing a lot of copper by the end of the year. This new plant could handle low-quality ore. By mixing different ores, they could make the process even better.

In 1911, the smelter had to close for two months because of problems in the mine. Still, they produced a lot of copper in 1911 and 1912. Many of the buildings you can still see today were built around this time.

Problems started for Mount Elliott in 1913. A fire closed one mine for months. A long strike also caused many workers to leave. Even with these issues, the company paid good profits that year.

At the end of 1914, smelting stopped for over a year because they didn't have enough ore. Copper production dropped a lot. For a while, the smelter processed ore from another mine. In 1916, the smelting plant was taken apart, except for the chimneys. A new, bigger furnace was built.

The new, larger furnace started in June 1917. But worker strikes continued to slow down production. The company decided to close the smelter in October and make the furnace smaller. Meanwhile, the price of copper had almost doubled because of the war.

The new, smaller furnace started on January 16, 1918. It smelted a lot of ore and produced much copper. This copper was sent to England. Getting coal and coke was a problem, as it came from far away. The smelter worked well for almost a year, except for a few strikes. In 1919, copper prices dropped sharply. The smelter closed after only two months, and most workers lost their jobs.

From 1919 to 1922, Corbould tried to get more money for the company but failed. He left the company in 1922. The Mount Elliott Company took over other companies in the 1920s. Mount Isa Mines bought Mount Elliott's equipment in 1943. This helped them start making copper during Second World War. The Mount Elliott Company officially closed in 1953.

Later, in 1988, a new open-cut mine started nearby. In the 1990s, more copper-gold deposits were found deep under the old smelter. New mining started there in 1993.

Life in Selwyn Township

In 1907, the first hotel opened in Selwyn. The town was officially planned around 1910. It was located north of the mine and smelter, near the railway. The town was named after the nearby Selwyn Ranges. It was also sometimes called Mount Elliott.

Most people in Selwyn worked at the mine or smelter. Others worked in shops and services that supported the mining operations. We don't know much about daily life there. But we do know that meat was cheap because of nearby farms. Vegetables were brought to town by horse and cart. However, other goods brought from far away were expensive.

By 1910, Selwyn had four hotels. It also had stores, a butcher, a baker, a police station, a hospital, banks, and a post office. There was even an orchestra! The town's population grew from 1000 in 1911 to 1500 in 1918. After that, it slowly became smaller.

What You Can See Today

Mount Elliott Smelter Remains

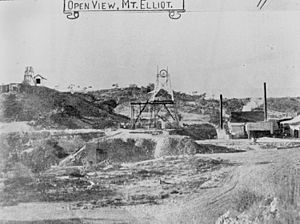

The Mount Elliott Smelter is about one kilometer south of where Selwyn town used to be. The main parts of the old processing area are on the north side of a small hill called Mount Elliott.

North of the main area, you can find the remains of the powerhouse and boiler house. There's also an ore tunnel, a beehive kiln, and old railway tracks.

To the east, you can see what's left of an assay office and furnaces. There are also remains of places where explosives were stored. You can also find old tank stands and parts of a large house.

To the south-west, on the small hill, are the remains of a winder engine. This engine helped lift things from the mine. There's also a brick chimney and parts of the main ore crusher.

Further west, on low ridges, you can find the remains of a strong room, an office, a stone tank stand, and a blacksmith's shop.

Selwyn Township Remains

The Selwyn Township is at the northern end of a valley. The Mount Elliott Smelter is about 1.5 kilometers away. All the buildings are gone now. What's left are garden plots, concrete surfaces, and old water tanks.

You can still find the spot where the Union Hotel stood. The wooden stumps of the stationmaster's house are also visible. The old railway line and some wooden sleepers can be seen too. The railway track follows the eastern side of the valley. Along the way, you might see old miner's hut sites with stone walls.

Other places you can identify include a concrete surface where the school building once stood. There's also the site of the police station. The original smelter site is at the base of a hill on the western side of the valley.

The town cemetery is about 200 meters south-east of the town. It has about fifteen headstones. These are in separate areas for Catholics and Protestants. The graves include three women, a soldier who died in the mine, and a man who died in the local hospital.

Why Mount Elliott is Important

The Mount Elliott Mining Complex is listed on the Queensland Heritage Register. This means it's a very important historical site. It helps us learn about Queensland's past, especially about early copper smelting and mining. It also tells us about the people who lived and worked in this mining area.

Studying the Mount Elliott Complex can give us important information. We can learn about the daily lives of the people who lived there. This includes their culture, how much money they had, and how they adapted to living in a remote and tough environment.

Looking at the old mining and smelting equipment can help us understand:

- How an early metal processing plant worked in Queensland.

- How people changed their work because of the remote and harsh conditions.

- The important changes W.R. Corbould made to copper mining and smelting. He found ways to make production more efficient and cheaper.

The Mount Elliott Mining Complex is a key part of the history of mining in the Cloncurry region. The remains of the buildings, mining tools, and the town of Selwyn are important. They can be compared to other mining sites nearby. Studying Mount Elliott can help us learn more about these old mining businesses. It also teaches us about the everyday lives of people who worked at such sites across Queensland.

See also

- Mount Elliott Company Metallurgical Plant and Mill

- Mount Elliott mine

| William M. Jackson |

| Juan E. Gilbert |

| Neil deGrasse Tyson |