Passivation (chemistry) facts for kids

Passivation is a cool process where a material becomes super strong against something called corrosion. Think of corrosion as rust or damage that happens when a material reacts with its surroundings, like metal rusting in air and water.

When a material is "passivated," it gets a special, very thin outer layer. This layer acts like a shield, protecting the material underneath from getting damaged. This protective shield is often called a microcoating because it's incredibly thin, almost invisible!

Passivation doesn't just happen anywhere. It needs specific conditions to work. It's a very important technique used in many areas, especially in making tiny electronic parts, like those found in your phone or computer.

Contents

What is Passivation?

Passivation makes a material more resistant to damage. It's like giving a metal a superhero suit. This suit stops the metal from reacting with things that would normally harm it.

The word "passivation" comes from "passive," meaning not active or not reacting. So, a passivated material becomes less active and doesn't react easily with its environment.

How Does Passivation Work?

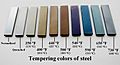

Passivation creates a very thin, non-reactive layer on the surface of a material. This layer is often made of the same material as the object itself but in a different form. For example, on steel, it might be a thin layer of iron oxide. This oxide layer is different from rust. Rust is flaky and doesn't protect the metal. A passivated oxide layer is very stable and sticks tightly to the surface.

This protective layer acts as a barrier. It stops harmful substances, like oxygen or water, from reaching the main material. Because these substances can't touch the material, they can't cause corrosion.

Where is Passivation Used?

Passivation is used in many places to protect materials.

- Stainless Steel: This is a great example. Stainless steel naturally forms a thin, protective layer of chromium oxide. This layer is what makes stainless steel "stainless" and prevents it from rusting easily.

- Electronics: In tiny electronic devices, passivation protects delicate parts. It stops them from corroding and helps them last longer. This is super important for things like computer chips.

- Medical Tools: Surgical instruments are often passivated. This makes them resistant to rust and keeps them clean and safe for use.

- Aerospace: Parts of airplanes and spacecraft are passivated. This protects them from harsh conditions in the air and space.

Types of Passivation

There are different ways to create this protective layer.

- Natural Passivation: Some materials, like stainless steel or aluminum, can form a protective layer on their own when exposed to air.

- Chemical Passivation: This involves dipping a material into a special chemical solution. The chemicals help form the protective layer faster and more effectively.

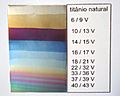

- Electrochemical Passivation: This method uses electricity to create the protective layer. A process called anodizing is an example of this. Anodizing is often used on aluminum to create a thicker, more durable protective layer, which can even be colored!

Benefits of Passivation

Passivation offers many advantages:

- Prevents Corrosion: This is the main benefit. It stops materials from rusting or degrading.

- Extends Lifespan: By preventing damage, passivation helps products last much longer.

- Improves Cleanliness: For things like medical tools, a smooth, corrosion-resistant surface is easier to clean and keep sterile.

- Enhances Appearance: Sometimes, the passivated layer can also make the material look better, like the vibrant colors seen on anodized titanium.

Passivation is a clever way to make materials stronger and more durable. It's a key process in keeping many of the things we use every day in good working order.

Images for kids

See also

In Spanish: Pasivación para niños

In Spanish: Pasivación para niños

| John T. Biggers |

| Thomas Blackshear |

| Mark Bradford |

| Beverly Buchanan |