Pierre-Émile Martin facts for kids

Quick facts for kids

Pierre-Émile Martin

|

|

|---|---|

|

|

| Born | 18 August 1824 |

| Died | 23 May 1915 (aged 90) Fourchambault

|

| Nationality | French |

| Occupation | Engineer |

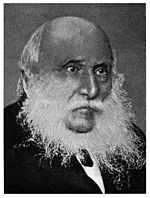

Pierre-Émile Martin (born August 18, 1824, in Bourges, Cher – died May 23, 1915, in Fourchambault) was a clever French engineer. He became famous for his important work in making steel. He used a special method to recycle hot gases in a furnace. This idea was first thought of by Carl Wilhelm Siemens.

In 1865, Martin took Siemens's idea and created his own way to make steel. This method is now called the Martin process. It involved melting old scrap steel and adding cast iron. This helped to make the steel cleaner and stronger.

His hard work was recognized with many awards. He received the Bessemer Gold Medal in 1915. This award is very important in the world of iron and steel. He also received honors from France, becoming a Knight in 1878 and an Officer of the Legion of Honour in 1910.

Contents

What is Martin Steel?

The metal made using Pierre-Émile Martin's method was known as Martin steel. This type of steel was much cleaner than steel made with other processes at the time. It had fewer unwanted materials, and its exact makeup could be controlled better.

Why Martin Steel Was Special

The Martin process allowed factories to use scrap steel and cast iron. This was a big step forward for recycling materials. Many people thought Martin steel was better quality than steel made using the Bessemer process. However, making Martin steel took more time. This also meant it cost more to produce.

The new method was first tested at the Sireuil foundry in Charente, France. It worked very well! Martin steel even won a Gold Medal at the Paris Exhibition in 1867. This showed how important his invention was.

The Martin-Siemens Process

The way Pierre-Émile Martin refined steel is often called the Martin-Siemens process. It involves melting a mix of cast iron and either scrap metal or iron ore. Then, the melted metal is cleaned. This cleaning process removes carbon, sulfur, and phosphorus. These are all impurities that can weaken steel.

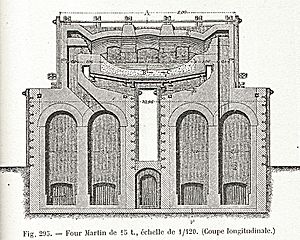

How the Furnace Works

This special method uses a type of furnace called a reverberatory furnace. It's heated by gas. A key part of this furnace is that it reuses heat from the waste gases. This idea came from Carl Wilhelm Siemens. By reusing the heat, the furnace becomes much more efficient.

Using this process, it became possible to make very high-quality steels. These included "fine steels" and "alloy steels." Alloy steels are made by adding other special metals to create steel with specific properties.

| Mary Eliza Mahoney |

| Susie King Taylor |

| Ida Gray |

| Eliza Ann Grier |