Pogo mine facts for kids

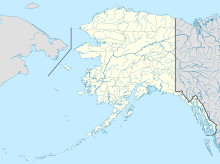

| Location | |

|---|---|

| Location | Delta Junction |

| Alaska | |

| Country | United States |

| Coordinates | 64°27′0″N 144°54′44″W / 64.45000°N 144.91222°W |

| Production | |

| Products | Gold |

| Production | 205,878 troy ounces |

| Financial year | 2020 |

| History | |

| Opened | 2006 |

| Owner | |

| Company | Northern Star Resources |

| Website | www.nsrltd.com |

| Year of acquisition | 2018 |

The Pogo mine is a gold mine located in the state of Alaska in the United States. It's a place where people dig deep underground to find valuable gold. The mine started operating in 2006.

By the end of 2017, the Pogo mine had already produced 3.6 million ounces of gold. In 2020 alone, it produced over 205,000 ounces of gold. The mine is owned by a company called Northern Star Resources Ltd. It is found about 30 miles (48 km) northeast of Delta Junction and 90 miles (145 km) east of Fairbanks.

Contents

How Gold is Mined at Pogo

The gold at Pogo is found in many quartz veins. These are like thin cracks in the rock filled with quartz, which also contains gold. The veins can be from 2 to 40 feet (0.6 to 12 meters) thick. Usually, they are about 8 to 20 feet (2.4 to 6 meters) thick.

The rock layers where the gold is found are quite complex. They are often broken and shifted by natural cracks called faults. This makes the gold deposits a bit "chopped up."

Mining Methods Used

For many years, the Pogo mine used methods called "drift-and-fill" and "cut-and-fill" mining. These methods involve digging out sections of rock and then filling them back in. This helps support the ground as miners go deeper.

In 2019, the mine changed its main digging method. It now uses something called "longhole stoping." This method is often more efficient for certain types of rock formations.

Getting to the Gold

Miners get to the gold by using a decline and a spiral ramp. A decline is a sloping tunnel that goes down into the earth. A spiral ramp is like a circular road that winds down, allowing trucks and equipment to move between different levels of the mine.

After the rock is blasted, the gold-containing ore is loaded onto trucks. These trucks take the ore to a central storage area underground called an "ore bin." From there, a conveyor belt carries the ore directly out of the mine to the mill. The mill is where the gold is separated from the rock.

Every day, the mine produces about 2,500 tons of ore. From this, they get around 1,000 troy ounces of gold.

Using Paste Backfill

The Pogo mine uses a clever system called "paste backfill." After the gold is taken out of the rock, the leftover material is called "tailings." Instead of just storing all these tailings on the surface, about 20% of them are mixed with cement. This mixture becomes a thick paste.

This paste is then pumped back underground into the empty spaces where the ore was removed. This helps to support the ground and makes the mine safer. It also has a good environmental benefit. By putting some of the tailings back underground, the mine needs less space on the surface to store them. This reduces the mine's overall footprint on the land.

The Moose Incident

During the construction of the mine on October 5, 2004, something unusual happened. A large moose with very wide antlers got tangled in some new power cables. As the cables were being tightened, the moose was accidentally lifted into the air.

After the moose was brought back down, it was in a lot of distress. Sadly, it had to be put down.

| Emma Amos |

| Edward Mitchell Bannister |

| Larry D. Alexander |

| Ernie Barnes |