Richmond Main Colliery facts for kids

Quick facts for kids Richmond Main Colliery |

|

|---|---|

Heritage boundaries

|

|

| Location | South Maitland Coalfields, Kurri Kurri, New South Wales, Australia |

| Built | 1908–1913 |

| Built for | J & A Brown |

| Demolished | 1967 (partly) |

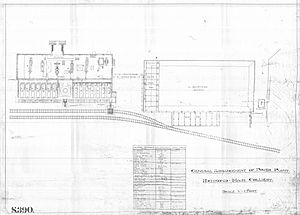

| Architect | J & A Brown's Engineering Workshops, Hexham |

| Owner | Cessnock City Council |

| Official name: Richmond Main Colliery; Richmond Vale Colliery; South Maitland Railway (SMR) | |

| Type | state heritage (complex / group) |

| Designated | 2 April 1999 |

| Reference no. | 16 |

| Type | Other - Mining and Mineral Processing |

| Category | Mining and Mineral Processing |

| Builders | The J & A Brown Company |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Richmond Main Colliery was once a very important coal mine in New South Wales, Australia. Today, it is a special open-air museum where you can learn about its past. The mine was designed by the J & A Brown company and built between 1908 and 1913.

Now, the site is called Richmond Main Heritage Park. It includes the Richmond Vale Railway Museum and the Richmond Main Mining Museum. The local council, Cessnock City Council, owns the property. This historic site was added to the New South Wales State Heritage Register on April 2, 1999.

Contents

- History of Richmond Main Colliery

- Buildings and Structures

- Administration Building

- Passenger Rail Platform

- Cooling Tower Dam

- Cooling Towers

- Under Manager's Office

- Main Shaft Building

- Screens and Bins Area

- Power Station

- Water Tube Boiler House

- Loco Shed and Store

- Workshops

- Transformer Building

- Fan and Compressor Building

- No.1 Shaft Winding Engine House

- No.3 Shaft Winding Engine & Ventilation Fan Building and Shaft

- Grain Silos

- Why Richmond Main Colliery is Important

- See also

History of Richmond Main Colliery

Richmond Main Colliery was one of the biggest and most important deep coal mines in the early 1900s. It is located in an area once known as Richmond Vale. This area was part of the larger South Maitland coal field. Before coal mining, the land was used for farming.

Discovering Coal

In the 1880s, a government geologist named Tannat William Edgeworth David found rich coal seams here. These coal layers became known as the Greta Coal Measures. His discovery led to a mining boom, and many people wanted to start coal businesses.

Starting the Coal Company

In 1886, a group of business people from Melbourne formed the Richmond Vale Coal Company. They bought the Richmond Vale Estate in 1887. They drilled into the ground and found a thick coal seam, about 4.4 meters (14.5 feet) thick, at a depth of 212 meters (696 feet).

They started digging a shaft, which is a deep hole, in October 1888. This shaft was 3.7 meters (12 feet) wide and finished in August 1890. The company then tried to get money to build the mine and a railway line. They were not successful. A new company was formed in 1895, but it also failed to raise enough money. So, the property was sold at an auction in July 1897. The J & A Brown company bought it for £39,500.

Building Railways and Other Mines

In 1900, J & A Brown wanted to build a railway line to the Richmond Vale Colliery. This railway would connect to their existing line. The government approved the Richmond Vale Coal-mine Railway Act on October 20, 1900.

Before building the Richmond Vale Railway, the Browns bought another mine nearby called Stanford Greta Colliery. This mine was easier and cheaper to develop because it was a "drift colliery," meaning it went into the coal seam from the surface. In 1901, Stanford Greta Colliery was renamed Pelaw Main Colliery. It started producing coal in November 1901.

J & A Brown's own Richmond Vale Railway began construction in early 1904. The line to Pelaw Main was finished in June 1905. The branch line to Richmond Vale Colliery was completed in August 1905.

Developing Richmond Main

After the railway was built in August 1905, the mine was drained of water. More development work began in 1910. This included digging the main No. 2 shaft and ordering big equipment like the head frame, boilers, and power station machinery. John Brown, the owner, spent a lot of money to make sure his mines and railways used the best technology.

In August 1911, the mine's name changed from Richmond Vale Colliery to Richmond Main Colliery. Digging the No. 2 shaft stopped for a while in 1912 so the permanent headframe could be built over it. Also in 1912, the power station and boiler house were built. The colliery office was built in 1913. To make bricks for the buildings, a brickworks was built nearby. This brickworks made the special "Richmond Main red" bricks used at the mine.

In July 1914, the No. 2 shaft was finished. It was 6.7 meters (22 feet) wide and lined with bricks from top to bottom. It was considered one of the best shafts in the country.

In 1914, the mine produced 9,670 long tons (9,825 tonnes) of coal. By 1915-1916, the elevated walkway from the main shaft to the coal screening buildings was being built. The screening buildings and railway sidings were also under construction. The mine faced strikes by workers, which slowed down production. In 1916, the locomotive shed and a large coal bin were built. The main pit top and screening plant were finished by June 1917. By 1918, the mine was producing a lot of coal, reaching 167,000 long tons (169,680 tonnes).

Peak Production and Decline

The colliery reached its highest yearly production in 1928, selling 507,000 tons of coal.

However, the mine faced many challenges. The 1929 Lockout (a time when mine owners locked out workers) and the Great Depression caused big problems. Later, the 1949 strike and a general slowdown in the coal industry, along with new machine-based mining methods in the 1950s and 1960s, led to its decline.

On July 7, 1967, Richmond Main Colliery stopped operating. This left eighty mine workers without jobs. This was a much smaller number than the 1,200 people who worked there in the late 1920s. The colliery continued to supply electricity until 1976. Many machines were removed and sold for parts, and the main head frames were taken down.

Saving the Site

The local council bought the site to turn it into a mining park. In 1979, the Richmond Vale Preservation Co-op Society Ltd was formed. This group has worked hard to restore some of the buildings and machines. They have also relaid the railway line. The society now runs the Richmond Vale Railway Museum at the old colliery.

Changes Over Time

- 1908-1913: The first buildings, like the Power House and main shaft, were constructed.

- 1914-1921: More buildings were added, including the main ventilation machinery.

- 1921-1925: Several buildings, like the Fan Building, were expanded. A passenger rail platform was built.

- 1926-1928: Boilers were replaced, and a third shaft with its buildings was dug.

- 1980s: The railway line was relaid.

Buildings and Structures

Many of the original buildings and structures at Richmond Main Colliery still stand. They show how the mine operated.

Administration Building

Built in 1913, this two-story building looks like a large house from the late Victorian era. It has a simple rectangular shape with a long hallway on each floor. It is made of the special "Richmond Main red" bricks. The roof is slate, and the verandah has a curved, corrugated iron roof. The ground floor had offices for mine managers. The top floor had a laboratory, kitchen, bedrooms, and a large lecture room. There was also a strong room underground for keeping important records.

Passenger Rail Platform

This is a simple platform made of concrete and earth.

Cooling Tower Dam

This dam was built into the ground with brick walls and a concrete lining. It could hold 11.8 million liters (2.6 million imperial gallons) of water. Water was brought to it through a pipeline from another dam.

Cooling Towers

There were Southern and Eastern cooling towers. These were tall, steel-framed structures. Their lower parts were covered in concrete and stood on concrete foundations. A concrete pool was at the bottom. The walls were made of timber, with the lower parts having timber louvres (slats). Inside, there were many timber racks and slats to help cool the water.

Under Manager's Office

This was a small, one-story building with a simple pitched roof. It was also made of "Richmond Main red" bricks. Today, there are no original items left inside.

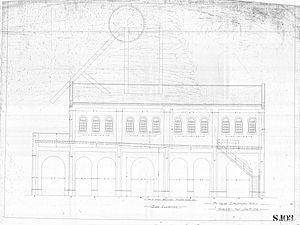

Main Shaft Building

This large, two-story concrete building was built over the main No. 2 shaft. The headframe, which is a tall structure used to lift things from the mine, passed through its roof. The building has arched openings and windows. Its walls are made of thick concrete. A metal staircase leads to the first floor, which has timber planks on steel. The roof is made of steel frames and corrugated iron.

The headframe and cages (lifts) for the No. 2 shaft were ordered from England in 1910. The headframe was 27.4 meters (90 feet) tall and had two large pulleys, each 5.5 meters (18 feet) wide.

This main shaft building was unusual because its walls were made of concrete, while most other mines at the time used timber. It was also unique because the pit top building was separate from the coal screening area. The building had two levels for coal skips (small wagons) to enter and leave the double-deck cages.

After the mine closed in 1967, the headframe, cages, and skip lines were sold for scrap. In 1986-1987, the building got a new roof, but no other major repairs have been done.

Screens and Bins Area

This area had strong pillars made of reinforced concrete.

Power Station

This building was made to hold the electric winding machine for the No. 2 shaft, along with generators and electrical equipment. It has a T-shape and two stories with a steel-framed roof. This building's design, with its brick walls, arched windows, and detailed gables, influenced the look of other buildings at the colliery. It has a porch with a double staircase. The bricks for the power station were bought from an outside company, unlike the "Richmond Main red" bricks. Inside, there is a 20 long tons (20 tonnes) crane that runs the length of the building.

The power station building was partly restored in 1987-1988, with a new roof and fresh paint.

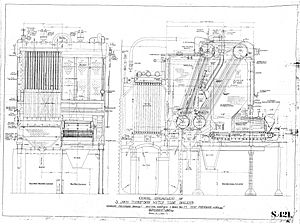

Turbines

The power station had several large turbines that generated electricity.

- Willans & Robinson Turbines: The first two turbines were installed in 1912-1913. They were made in England. One of them was later moved and renumbered. By the 1950s, both were no longer in use and were scrapped, though parts of their condensers remain.

- Fraser & Chalmers 3000kW Turbine: This turbine was ordered in 1921 to meet the growing demand for electricity. It arrived in November 1922 and cost £18,343. This turbine stayed in use until the power station closed in 1976 and is still in place today.

- Fraser & Chalmers 6000kW Turbine: This even larger turbine was ordered in 1926 to help with increased coal production. It arrived in July 1927 and cost £13,529. This turbine also stayed in use until the power station closed in 1976 and is still there.

Electric Winder

Ordered in 1910, this machine was used to pull the cages up and down the shaft. It was powered by an 800 Volt DC electric motor. The winding engine was cut up for scrap after the colliery closed in 1967.

Motor Generator Sets

These machines converted AC power to DC power for the winding engine.

- Siemens Brothers Set: Installed in 1911-1912, it generated 800V DC power. It was removed when the colliery closed in 1967.

- Metropolitan Vickers Set: This set was bought in 1926 but was later used as a backup when the Siemens set needed repairs in 1951. It was also removed in 1967.

Water Tube Boiler House

This building housed three large water tube boilers. It is a steel-framed building with corrugated asbestos sheets, located next to the turbine room. Inside, it is filled with furnace and boiler equipment. There is also a 24.4 meter (80 feet) tall steel chimney nearby.

Coal for the boilers was brought by train and unloaded into a hopper. A conveyor system then carried the coal to bunkers above the boilers. The coal from Richmond Main burned too fiercely, so coal from a different seam was brought in. In 1949, the boilers were changed to burn lower-quality coal. By 1955, they were modified again to burn waste coal from a coal preparation plant. The boilers were used until the power station closed in 1976.

John Thompson Water Tube Boilers

These three boilers were ordered in 1926 to provide high-pressure steam for the new 6000kW turbine. They arrived in 1927 and cost £17,913. Construction of the first boiler began in September 1928. All three boilers were completed by July 1930. They were used until the power station closed in 1976.

There are also other buildings to the southeast of the turbine room, which were once where the original boilers were located.

Loco Shed and Store

The loco shed is a one-story brick building with arched doors. It is connected to a similar-sized store building. Both have steel-framed roofs. The loco shed had a slate roof, and the store had a corrugated iron roof.

The loco shed was built in 1918 to house the locomotives (trains) used at the colliery. Later, it was turned into a store, and the train tracks inside were filled in. Today, the loco shed and store are the main maintenance area for the Richmond Vale Railway Museum.

Workshops

These are long, low, one-story brick buildings. They have pitched roofs with several cross gables. The original middle section has large timber frames.

Transformer Building

This is a two-story brick building with a gabled roof. The switch tower was built in 1921-1922 when a power line was built to other collieries. The substation next to it was made larger during World War II. It was expanded again in the 1950s and 1960s to connect to other power stations.

After the power station closed in 1976, the substation was still used to supply power to another colliery and a coal preparation plant. When those closed in the late 1980s, the power lines and equipment were removed.

Fan and Compressor Building

The older part of this building is on the northern end. It is made of "Richmond Main red" bricks with a timber-framed roof and slate tiles. The newer southern part has imported ceramic tiles.

No.1 Shaft Winding Engine House

This is a single brick building with red bricks and gabled end walls.

No.3 Shaft Winding Engine & Ventilation Fan Building and Shaft

This is a tall, concrete and steel building with brick panels and glass walls. It was built to hold a ventilation fan and an electric winding engine for the new No. 3 shaft. The fan is at ground level, and the winding engine floor is on the first level. A large crane was installed in the building. Although the electric winding engine was never fully installed, the building was used to store large machinery.

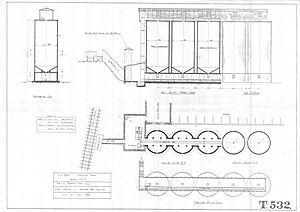

Grain Silos

These five round, reinforced concrete structures were built next to the mine's horse stables. Each silo is 4.3 meters (14 feet) wide and 14.1 meters (46 feet 3 inches) tall. They were meant to hold a total of 1.36 million liters (30,000 imperial bushels) of grain for the mine's pit horses. However, they were never fully finished.

The site was in fair condition when it was listed as a heritage site. It also has potential for finding old items buried underground.

Why Richmond Main Colliery is Important

Richmond Main Colliery is important because it shows a special time in the history of the South Maitland coalfields in the early 1900s. It represents the fast growth of the coal industry and the communities that grew around it. Even though some parts are gone, enough remains to tell its story.

Richmond Main Colliery was added to the New South Wales State Heritage Register on April 2, 1999, for these reasons:

Historical Importance

Richmond Main is historically important because of its strong connection to John Brown, its role in the South Maitland collieries, and how it helped a large community grow in the coalfields. Many of the remaining buildings show how they were used in the early 1900s. Even with some parts missing, there is enough evidence to understand its past.

Design and Technical Achievement

Richmond Main has some artistic value because of the size of its buildings, the consistent use of materials, and the clever architectural details. While not totally unique, its large scale and cooling towers stand out. John Brown wanted Richmond Main to be his best mine and a showcase for the industry. So, even in its partly ruined state, it represents other collieries of that time.

Community Connection

The growth of the South Maitland coal fields led to the creation of entire communities, like Cessnock and Kurri Kurri. In just ten years, the area changed from a quiet farming region to a key source of coal for the state. The collieries in this area have become a focus for the community's identity. Richmond Main is important because it helps these communities remember their past.

Potential for Learning

John Brown built Richmond Main to be a modern mine, using the latest coal mining technology and electric power generation. Old technology was replaced by new technology several times, especially with machines in the 1950s. Even so, there is still enough physical evidence to help us understand the mine's history. This makes Richmond Main a valuable place for learning about regional and industrial history.

See also

- City of Cessnock

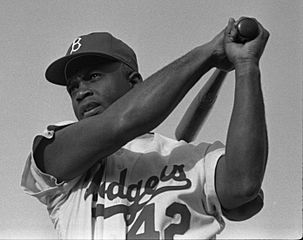

| Jackie Robinson |

| Jack Johnson |

| Althea Gibson |

| Arthur Ashe |

| Muhammad Ali |