Rock Bolting Development Site facts for kids

Quick facts for kids Rock Bolting Development Site |

|

|---|---|

|

|

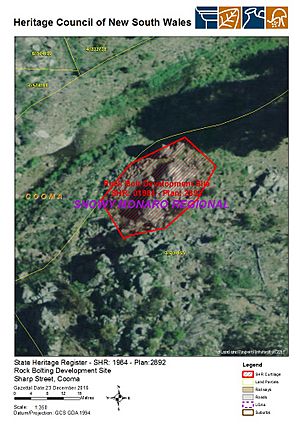

| Location | Sharp Street, Cooma, Snowy Monaro Regional Council, New South Wales, Australia |

| Built | 1956–1962 |

| Architect | Snowy Mountains Hydro-Electric Authority Personnel |

| Owner | Department of Trade & Investment --Crown Lands |

| Official name: Rock Bolting Development Site; Cooma Back Creek; Scientific Services Division; SMHEA | |

| Type | state heritage (built) |

| Designated | 23 December 2016 |

| Reference no. | 1984 |

| Type | Other - Scientific Facilities |

| Category | Scientific Facilities |

| Builders | Snowy Mountains Hydro-Electric Authority personnel |

| Lua error in Module:Location_map at line 420: attempt to index field 'wikibase' (a nil value). | |

The Rock Bolting Development Site in Cooma, New South Wales, is a special place. It was once a test site for a new way to make underground tunnels and caverns safe. From 1956 to 1962, experts from the Snowy Mountains Hydro-Electric Authority worked here. They developed a method called "patterned rock bolting." This method helped prevent large underground spaces from collapsing. The site is now recognized for its importance. It was added to the New South Wales State Heritage Register on December 23, 2016.

Contents

How Rock Bolting Changed Tunnel Building

From the mid-1950s to the early 1960s, the Snowy Mountains Hydro-Electric Authority (SMHEA) created an amazing new technique. They found a way to stop huge tunnels and caverns from falling in. This was done using a system called "patterned rock bolting." The bolts were placed in a special way, depending on the rock's structure.

This new method was shared all over the world. Many countries started using it. Even today, the basic ideas and equipment are still the same. They were first developed by the Snowy Mountains Authority.

Testing Rock Bolts at Cooma

The Cooma Rock Bolting Development Site was part of the Authority's Scientific Services Laboratory. Here, scientists tested and improved the rock bolting method. In a place called Lambie Gorge, they did "pull-out" tests. These tests made sure that the rock bolt's anchor was as strong as the bolt itself. If you visit the site, you can still see drilled holes and old rock bolts in the rock faces. This shows where the tests happened.

Many engineers and workers from SMHEA helped with this project. They worked in labs and at the underground construction sites. They also found quick ways to install the rock bolts. This made the whole project more effective. The work done in the gorge helped approve the use of rock bolting for the Snowy Mountains Scheme.

Making Rock Bolting Permanent

It was very important for the rock bolting design to be permanent. This meant sealing the entire bolt system. It also meant changing the pulling force of the bolts into a lasting pushing and locking force. This part of the development was tested in the labs. It was then made even better during actual construction.

The Cooma Rock Bolting Development Site is a great place to remember this invention. It shows how patterned rock-bolting helped the field of rock mechanics. This was a team effort by SMHEA engineers. It led to much faster tunnel building. It also saved a lot of money and made workers safer. Everyone involved felt proud and excited about their work.

On October 18, 2009, Engineers Australia named the site a National Engineering Heritage Landmark. This is the highest award for heritage given by Engineers Australia. A special plaque and sign were put up at the site. This event happened during the 60th anniversary of the Snowy Mountains Scheme.

How Rock Bolting Works

Rock bolting in hard rock starts with drilling a hole. This hole goes into strong rock, usually 1.5 to 6 meters deep. The hole is about 45 mm wide. A steel rod, called the bolt, is then put into the hole. It has a special part at the end that expands.

At the other end, the bolt has threads and a nut. Under the nut is a small steel plate. This plate has a rubber seal that closes the hole when grout is added. When the nut is tightened, the expanding part anchors the bolt in the hole. This allows a certain amount of tension to be put on the bolt. The goal is for the anchor to hold the bolt's full strength.

Next, the hole around the bolt is filled with a special grout. This grout does not shrink and pushes out any air. When the grout dries, it creates a strong bond between the bolt and the rock.

When the bolt is tightened, it pushes against the rock surface. This creates forces that stop the rock from moving. These forces make a strong "membrane" across the rock face. This helps to balance the natural forces inside the rock.

The special non-shrinking grout helps the bolt transfer its load to the rock along its whole length. It also stops the bolt from rusting. The formula for this grout was a clever idea from SMHEA engineers.

"Pull-out" tests were done at the Rock Bolting Development Site. These tests collected information to show how strong the anchor was compared to the bolt itself. About a dozen rock bolts were used here to prove the grout's effectiveness and the anchor's strength.

Many other steps were taken in SMHEA's labs. They wanted to create a complete rock bolt system. This system would be permanent and protected from rust.

Benefits of Rock Bolting

In most cases, rock bolting could replace the need for steel supports. It also meant less digging to make space for these supports. It could even avoid the need for separate concrete supports underground.

It's thought that rock bolting reduced the amount of steel needed for support. It was only one-eighth of what older methods required. It also saved money by avoiding extra digging. This meant less rock had to be removed. Contracts at the time showed that concrete-lined tunnels cost 45% more if steel supports were used instead of rock bolts.

These benefits saved a lot of time and effort. They also made tunnelling much safer for workers. Another time-saver was that rock bolts could be installed right after each part of the tunnel was dug. This happened at the same time as drilling for the next section.

Why Cooma Was Chosen

The Rock Bolting Development Site is on Cooma Back Creek in Lambie Gorge. It was chosen for its geology. The type of rock there, called Cooma gneiss, was similar to the granite at the real construction sites. These sites were for the underground power stations, Tumut 1 and Tumut 2, and their tunnels.

Another reason the site was useful was its location. It was close to the Engineering Laboratories of SMHEA's Scientific Services Division. The testing staff worked there with their equipment. All this land belonged to SMHEA. It had been used for six years for other experiments. The original SMHEA building and storage buildings are still there today (as of 2016). During the testing years, a footbridge allowed people to cross Cooma Back Creek. This connected the laboratories to the Rock Bolting Development Site.

What the Site Looks Like

The Rock Bolting Development Site is on the bank of Lambie Gorge. The Cooma Back Creek flows through this gorge. You can get to the site from Sharp Street in central Cooma. It's near the park that remembers the "Southern Cloud" airliner. A public path along the creek bank leads to it. You pass the Cooma Agricultural and Pastoral Society Showgrounds and the Cooma Bowling Club.

The site has a natural rock face with drilled holes. Some of these holes still have different types of bolts sticking out. In front of the main test area, you can see blasted, fallen rock. This shows that many tests were done here over time.

There are two main spots where the rock bolting tests happened. Many tests were done in the area at the downstream end of the gorge.

As of December 4, 2013, the holes and bolts were in great shape. They had not been moved or damaged. The broken rock and bolts from earlier experiments are still there.

The site still has many of the original bolts and drilled holes from the field tests. You can see evidence of many test faces. This is shown by the blasted, fallen rock in front of the main test area.

Why This Site is Important

The Rock Bolting Development Site is very important to the history of New South Wales. It's where a new Australian method for supporting underground tunnels was tested. This method used patterned rock bolting. It made tunnelling safer, faster, and cheaper than older ways. This technique quickly spread worldwide and is still used today.

The drilled holes and old rock bolts in Lambie Gorge show where "pull-out" tests happened. These tests proved that the rock bolt's anchor was as strong as the bolt itself.

Rock bolts had been used in coal mines since 1912. They mainly attached loose rock to stronger layers. Their use in hard rock started in Sweden in 1939.

However, these early methods were based on trial and error. They didn't have scientific guidance or lab tests. The Snowy Mountains Hydro-Electric Authority developed a full method for permanent support in hard rock. This happened between the mid-1950s and early 1960s. They used design research, testing, measurements, and trials.

The Rock Bolting Development Site was added to the New South Wales State Heritage Register on December 23, 2016. It met the following important reasons:

A Key Part of History

This site is important because of its role in the history of rock mechanics. This is a science about how rocks behave. In the 1950s and 1960s, huge steps were made here in rock digging and tunnelling. This new method greatly reduced costs. It also made workers much safer and sped up tunnelling projects.

Linked to Important People

The site is important because of its strong connection to the famous Snowy Mountains Hydro-Electric Authority. It is also linked to their expert staff. The new method was very important to major tunnelling companies.

Showing Great Achievement

The site is important for its beauty and technical value. The unique rock face and scattered rock pieces clearly show the creative thinking. This led to amazing research in the science of rock mechanics.

Valued by the Community

Many engineers in New South Wales and Australia highly respect the Rock Bolting Development Site. It is seen as the most important engineering development from the Snowy Scheme.

A Place to Learn From

The site still has its bolts and drill holes. It also has rock pieces from the experiments. This makes it important because it can still show us how rock bolting techniques were developed. The site also shows how important the Snowy Mountains Hydro-Electric Authority's work was around the world.

A Rare and Unique Place

This site is important because it is the only place in Australia where this kind of rock bolting development happened.

An Example of Engineering

The Rock Bolting Development Site is important as an example of engineering experiments. It greatly helped the development of engineering science in New South Wales, Australia, and the world.