Rocket engine test facility facts for kids

A rocket engine test facility is a special place where rocket engines are tested on the ground. These tests happen in a controlled way. Before a rocket engine can fly, it must pass many ground tests. Testing on the ground is much cheaper than risking a whole mission or the lives of a flight crew.

Rocket engine tests usually happen in two main ways: at "sea level" or at "altitude." Sea level testing is good for checking how a rocket starts when launched from the ground. But it doesn't show how the rocket will work high up in space. Altitude test facilities give a much better idea of how the engine will perform in space.

Contents

Testing at Sea Level

Testing rocket engines at sea level is simpler. The test facility just needs to hold the rocket still and safely direct the hot exhaust gases away. During these tests, engineers check if the rocket parts are strong enough. They also make sure all systems work and measure the engine's power at sea level. However, rockets mostly work in very thin air or no air at all. Things that work well on the ground might act differently in space.

How Sea Level Tests Work

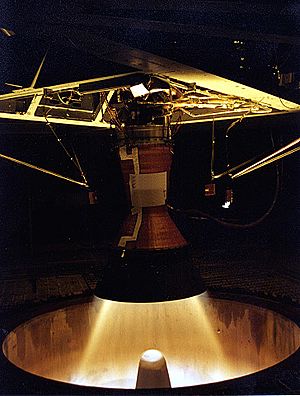

A typical sea level test stand can hold the rocket engine either flat (horizontal) or upright (vertical). Liquid rocket engines are usually fired upright. This is because their fuel pumps are designed to pull fuel from the bottom of the fuel tanks. Engineers must consider the changing weight of the fuel when measuring the engine's push. The rocket's hot exhaust goes into a special "flame bucket" or "trench." This trench sends the hot gases in a safe direction. It also has a water system that cools the exhaust and makes the loud sound quieter. Large rocket engines can be super loud, sometimes louder than 200 decibels. This is one of the loudest sounds ever made by humans.

Solid rocket engines can be tested either upright or flat. When tested flat, engineers don't need to worry about the changing weight of the rocket. The flame trench for a flat test might not need to be as strong. However, a water system might not be as good at reducing the sound for solid rockets.

Keeping Tests Safe

All test stands need strong safety rules. This is to protect against the huge power of a rocket engine if something goes wrong. Safety steps often include building the test stand far away from people or other important buildings. They also put thick concrete walls or dirt hills (berms) around the stand. Special gases like nitrogen or helium are used to stop explosive gases from building up.

Testing High Up (Altitude)

Testing at altitude gives a better idea of how the rocket will work in space. As you go higher, the air pressure gets lower. This lower pressure means the rocket engine can produce more power. It also changes how heat moves around the engine.

How Altitude Tests Work

An altitude test facility is much more complex than a sea level one. The rocket is placed inside a sealed chamber. Before the engine fires, most of the air is sucked out of this chamber, creating a vacuum. A typical chamber pressure is like being 100,000 feet (about 30 kilometers) up in the sky. Special pumps, often using steam, create this low-pressure environment. If the gases from the burning rocket fuel could be explosive, the chamber must be filled with a safe gas like nitrogen. This stops any explosive mixtures from building up inside the chamber or exhaust pipes.