Liquid-propellant rocket facts for kids

A liquid-propellant rocket is a type of rocket engine that burns special liquids called liquid propellants. Unlike rockets that use solid fuel, liquid rockets use fuel and an oxidizer (like oxygen) that are stored as liquids in separate tanks. These liquids are then mixed and burned in a combustion chamber to create a powerful push, called thrust.

Liquid propellants are great because they are quite dense, meaning a lot of energy can be packed into a small space. Also, the gases they produce when burned give a very strong push, which is called high specific impulse. This means the rocket can be very powerful without needing huge fuel tanks.

Contents

Types of Liquid Rockets

Liquid rockets can be designed in a few ways based on how many types of propellant they use:

- Monopropellant rockets use only one type of liquid. This liquid breaks down to create hot gas for thrust.

- Bipropellant rockets use two different liquids: a fuel and an oxidizer. This is the most common type. Examples of fuels are liquid hydrogen or RP-1 (a type of kerosene). Common oxidizers include liquid oxygen.

- Tripropellant rockets use three types of propellant, but these are very rare.

Some liquid rockets are called cryogenic engines. This means their fuel and oxidizer, like hydrogen and oxygen, are gases that have been turned into liquids by making them extremely cold.

Most liquid rocket engines can change how much thrust they produce. This is called throttling. Some can even be turned off and then restarted, which is very useful for space missions.

Why Use Liquid Propellants?

Liquid rockets have many cool features that make them useful for space travel:

- Testing Before Launch: You can test a liquid rocket engine before putting it on a rocket. This helps make sure it works perfectly, unlike solid rockets which are usually used up after one test.

- More Power: Liquid systems can give a stronger push (higher specific impulse) than solid or hybrid rockets.

- Reusable Engines: Many liquid rocket engines can be used again for several flights, like those on the Space Shuttle and Falcon 9 rockets.

- Better Control: Liquid rocket engines can swivel, meaning they can point in different directions. This allows for very precise control over the rocket's path.

- Adjustable Thrust: The amount of fuel flowing into the engine can be changed. This lets engineers control how much thrust the rocket produces during flight, helping to correct any errors in real-time.

- Start and Stop: Liquid rockets can be turned off and restarted multiple times during a flight. This is important for missions that need several bursts of power.

- Safer Shutdowns: In an emergency, liquid rockets can be shut down in a controlled way. This adds an extra layer of safety.

However, liquid rockets also have some challenges:

- Shifting Weight: As the rocket uses up its fuel, its weight changes a lot. Engineers must carefully manage this to keep the rocket stable.

- Tank Issues: The fuel tanks are often very thin. They need to be kept pressurized so they don't collapse, especially when flying through Earth's atmosphere.

- Sloshing Fuel: The liquid fuel can slosh around inside the tanks, which can make the rocket hard to control. Special walls inside the tanks, called baffles, help prevent this.

- Leaks: Liquid propellants can sometimes leak, especially very light ones like hydrogen. This can create dangerous, explosive mixtures.

- Complex Pumps: The pumps that move the liquid propellants are called turbopumps. They are very complex to design and can fail if not built perfectly.

- Cryogenic Challenges: Very cold propellants, like liquid oxygen, can cause ice to form. This ice can damage parts or block valves, leading to leaks or failures. Special procedures are needed to prevent this.

How Liquid Rockets Work

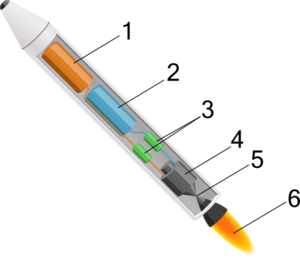

Liquid rocket engines have tanks and pipes to hold and move the fuel and oxidizer. They also have an injector system and one or more combustion chambers with nozzles.

Most liquid propellants are about as dense as water. One exception is liquid hydrogen, which is much lighter. The low density and pressure of liquid propellants allow for lightweight tanks.

To get the propellants into the combustion chamber, their pressure needs to be higher than the pressure inside the chamber. This is usually done with pumps. These pumps are often turbopumps, which are very powerful and light. Some designs use a tank of high-pressure gas, like helium, to push the propellants into the chamber instead of pumps. These rockets are simpler but often less powerful because the heavy gas tank takes up valuable space and weight.

So, the main parts of a liquid rocket engine are the combustion chamber, an igniter to start the burn, the system that feeds the propellants, valves, regulators, propellant tanks, and the nozzle where the hot gases shoot out.

Pressurization

Liquid propellants are often pushed into the combustion chamber using lightweight turbopumps. These pumps are usually powered by a small amount of the rocket's own fuel. Recently, some companies have started using electric pumps powered by batteries.

For smaller engines, a high-pressure inert gas (like helium) stored in a tank can be used to push the propellants. These engines are simpler and more reliable, which is why they are often used in satellites to keep them in orbit.

Types of Propellants

Scientists have tried thousands of different fuel and oxidizer combinations over the years. Here are some of the most common and effective ones:

Cryogenic Propellants

These propellants are gases that are cooled to extremely low temperatures to become liquids.

- Liquid Oxygen (LOX) and Liquid Hydrogen (LH2): This is a very powerful and clean-burning mix, producing only water vapor when burned. It's used in rockets like the Space Shuttle main engines, Space Launch System, and the upper stages of the Saturn V. The challenge is keeping liquid hydrogen super cold (around -253°C) and its very low density, which means huge, lightweight, insulated tanks are needed.

- Liquid Oxygen (LOX) and Liquid Methane (CH4): Methane is also known as liquefied natural gas (LNG). This combination is used in newer engines like SpaceX's Raptor and Blue Origin's BE-4. Methane offers a good balance of performance, density, and reusability, as it burns cleaner than kerosene and doesn't need heaters in space like some other fuels.

Semi-Cryogenic Propellants

These include one cryogenic component and one that is not.

- Liquid Oxygen (LOX) and RP-1 (Kerosene): This is a very common and reliable combination. It was used in the first stage of the Saturn V rocket, Soyuz rockets, and SpaceX's Falcon 9.

- Liquid Oxygen (LOX) and Alcohol (Ethanol): This mix was used in early liquid rockets, like the German V-2 rocket during World War II.

- Liquid Oxygen (LOX) and Gasoline: Robert Goddard used this combination in his very first liquid rocket.

Non-Cryogenic (Storable/Hypergolic) Propellants

These propellants can be stored at normal temperatures for long periods. Many of them are hypergolic, meaning they ignite instantly when they touch each other.

- T-Stoff (hydrogen peroxide) and C-Stoff (methanol and hydrazine hydrate): This was used in the Messerschmitt Me 163 Komet, a rocket-powered fighter plane from World War II.

- Unsymmetric Dimethylhydrazine (UDMH) and Dinitrogen Tetroxide (N2O4): This combination is used in the Proton rocket and the Long March 2 rockets, which launch the Shenzhou crew vehicles.

- Aerozine 50 (a mix of UDMH and hydrazine) and Dinitrogen Tetroxide (N2O4): This powerful mix was used in the Titan rockets, the Apollo lunar module, and Voyager 1 and Voyager 2 space probes.

- Monomethylhydrazine (MMH) and Dinitrogen Tetroxide (N2O4): This is used in the Space Shuttle orbiter's engines for maneuvering in space and in SpaceX's Draco engines for the Dragon spacecraft.

These non-cryogenic propellants are often toxic and can cause cancer, so they need careful handling. Because of this, some newer spacecraft are looking into using safer, non-toxic fuel combinations.

Injectors

Injectors are like showerheads for rocket fuel. They spray the fuel and oxidizer into the combustion chamber in a very specific way. A good injector design is super important because it makes sure the propellants mix well and burn completely. If they don't, some fuel might leave the engine unburnt, wasting energy.

Injectors also help protect the engine. By spraying more fuel around the edges of the chamber, they create a cooler layer that protects the walls from the extreme heat of combustion.

Early injectors simply sprayed parallel streams of fuel and oxidizer. Modern injectors often spray the liquids so they collide with each other, breaking them into tiny droplets that burn much more easily.

One special type is the pintle injector, which allows for excellent control over the fuel and oxidizer mix. It was used in the Apollo Lunar Module and is now used in the Merlin engines on SpaceX's Falcon 9 rockets.

Cooling

Rocket engines get incredibly hot! To prevent them from melting, they need to be cooled. A common method is regenerative cooling. This involves routing the fuel (or sometimes the oxidizer) through tiny channels in the walls of the combustion chamber and nozzle. The propellant absorbs heat from the hot walls, cooling the engine down, and then the now-warmer propellant enters the combustion chamber to be burned. This not only cools the engine but also preheats the fuel, which can improve performance.

Ignition

Starting a liquid rocket engine needs a strong and reliable ignition source. If there's a delay in ignition, too much propellant can build up in the chamber, causing a dangerous overpressure or even an explosion. This is called a "hard start."

Ignition systems usually create flames across the injector surface. Sometimes, safety systems are used to make sure the igniter is working before the main fuel valves open.

There are several ways to ignite a liquid rocket:

- Pyrotechnic: Using a small explosive charge or spark.

- Electrical: Using a spark plug or a hot wire.

- Chemical: Using hypergolic propellants that ignite instantly when they touch. These are very reliable. Sometimes, a small amount of hypergolic propellant is used to start the engine, and then the main propellants are switched on. This was done on the American F-1 rocket engine used for the Apollo program.

- Pyrophoric Agents: Some chemicals, like Triethylaluminium, ignite on contact with air or oxidizers. These are sometimes used as igniters.

History of Liquid Rockets

Russia – Soviet Union

The idea of a liquid-fueled rocket first appeared in 1903 in a book by the Russian scientist Konstantin Tsiolkovsky. He wrote about using liquid oxygen and liquid hydrogen and even thought about multi-stage rockets. Tsiolkovsky's ideas greatly influenced later rocket scientists, including Wernher von Braun.

In the 1920s and 1930s, Russian engineers like Valentin Glushko and Sergey Korolev worked to make Tsiolkovsky's theories real. Glushko developed many "ORM" (Experimental Rocket Motor) engines. In 1933, the first Soviet liquid-propelled rocket, the GIRD-9, was launched. It used liquid oxygen and jellied gasoline and flew to a height of 400 meters (about 1,300 feet).

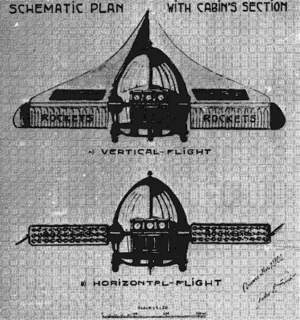

Peru

Peruvian scientist Pedro Paulet claimed he experimented with a liquid rocket engine in Paris around 1900. Some historians, including Wernher von Braun, have called Paulet a pioneer in liquid-fuel rocket motors. Paulet was even invited by Nazi Germany to help develop rocket technology, but he refused when he learned it was for weapons.

United States

The first actual flight of a liquid-propellant rocket happened on March 16, 1926, in Auburn, Massachusetts. American professor Dr. Robert H. Goddard launched a rocket named "Nell" that used liquid oxygen and gasoline. It only flew 41 feet for 2.5 seconds, landing in a cabbage field, but it proved that liquid-fueled rockets were possible! Goddard had been experimenting with them since 1921.

Germany

In Germany, engineers became very interested in liquid propulsion in the late 1920s. The Opel RAK program, the world's first rocket program, conducted tests. In 1929, Friedrich Wilhelm Sander launched two liquid-fuel rockets. These were the first in Europe and the second in the world after Goddard's.

Later, in the late 1930s, Germany seriously experimented with rocket propulsion for piloted flights. The Heinkel He 176 made the first piloted rocket-powered flight on June 20, 1939, using an engine designed by Hellmuth Walter. The only rocket-powered combat aircraft ever used in war, the Messerschmitt Me 163 Komet, also used a Walter-designed liquid rocket engine during World War II.

After World War II

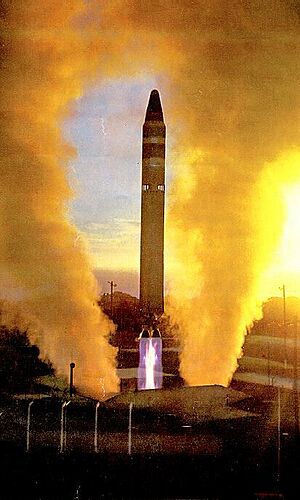

After World War II, both the American government and the Soviet Union started to seriously invest in liquid-propellant rockets for military and space uses. This led to the famous Space Race.

More recently, in the 2010s, 3D printing started to be used to make rocket engines. This has made it easier and faster to build complex engine parts for spaceflight. Examples include the SuperDraco engines used in the SpaceX Dragon 2 spacecraft.

See also

- Comparison of orbital launch systems

- Comparison of orbital rocket engines

- List of space launch system designs

| James Van Der Zee |

| Alma Thomas |

| Ellis Wilson |

| Margaret Taylor-Burroughs |