Tanning (leather) facts for kids

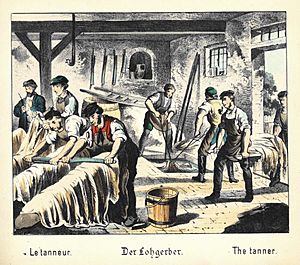

Tanning is a special process that turns animal skins and hides into leather. A tannery is the place where this work happens.

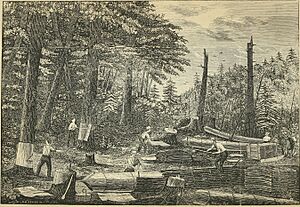

Long ago, people used natural plant materials like tree bark to tan skins. This method is called vegetable tanning. Later, in the 1800s, a new way was found using chemicals called chromium salts. This is known as chrome tanning.

Contents

History of Tanning

Tanning changes the skin's structure forever. It makes the skin much stronger and stops it from rotting. This is how animal hides become durable leather.

The word "tanning" comes from old words meaning "oak bark." This is because oak bark was often used in the tanning process.

Ancient people used leather for many things. They made water bags, carrying bags, and parts for horses. They also used it for boats, armor, and shoes. People in Pakistan were tanning skins as early as 7000 BCE. Around 2500 BCE, the Sumerians used leather on chariot wheels.

Tanning was also important for boats and fishing. Ropes, nets, and sails were treated with tree bark to make them last longer.

In the past, tanneries were often smelly places. They were usually built far away from towns. Skins would arrive stiff and dirty. First, tanners soaked the skins in water to clean and soften them. Then, they scraped off any leftover flesh or fat. Hair was removed by soaking skins in special mixtures or letting them sit for a while. After removing the hair, tanners would soften the skins using animal waste. This process used natural enzymes to make the leather soft.

The main tanning process back then used plant materials. Tanners would stretch the skin and apply things like cedar oil or plant tannins. The skin would then dry and soak up these materials.

In the 1840s, people found that using chromium solutions could also tan leather. This method became very popular.

Getting Hides Ready

The tanning process starts with getting an animal skin. This can be done by the tanner or by getting skins from places like farms.

Before tanning, hair, fat, and other tissues are usually removed. The skins are then washed and soaked in water with different compounds. This prepares them for the tanning agent. After this, they are soaked, stretched, dried, and sometimes smoked.

Curing Hides

Hides are first treated with salt. This stops tiny germs from growing and spoiling the skin. Salt removes water from the hides. This makes it hard for bacteria to grow. In wet-salting, hides are heavily salted and pressed for about 30 days. In brine-curing, hides are moved around in a saltwater bath for about 16 hours. Hides can also be kept fresh by storing them in very cold places.

Beamhouse Steps

The steps between curing and tanning are called beamhouse operations. They include soaking, liming, removing extra tissues, deliming, bating, and pickling.

Soaking Skins

In soaking, hides are put in clean water. This removes the salt from curing. It also adds moisture back into the skin. This makes the hide ready for the next steps.

Sometimes, special chemicals are added to the water. These chemicals stop bacteria from growing and damaging the skin.

Liming Process

After soaking, hides are treated with a lime mixture. This mixture often contains other chemicals like sodium sulfide.

This step does several things:

- It removes hair and other tough parts like keratin.

- It takes out some soluble proteins and fats.

- It makes the skin fibers swell and separate.

- It prepares the collagen in the hide for tanning.

The lime mixture weakens the hair. It breaks down the strong parts of the hair. This makes it easy to remove.

Any hair left after liming is scraped off by hand. This process is called scudding.

Deliming and Bating

The next step is to lower the pH of the collagen. This allows special enzymes to work on the skin. This process is called deliming. To make the leather softer, hides might be treated with enzymes. This is known as bating. Today, pure enzymes are used, so animal waste is no longer needed.

Pickling the Hides

Pickling is a step that prepares the hides for tanning. After bating, hides are soaked in a bath of salt water. Then, a small amount of sulfuric acid is added. Smaller skins stay in this liquid for a couple of days. Larger skins might stay for a week or even up to two months.

In vegetable tanning, hides soak in a solution with plant tannins. These tannins come from things like tree bark or leaves. Vegetable tanning takes longer than mineral tanning. Leather made with mineral tanning is often used for shoes and car seats. Vegetable-tanned leather is used for crafts, wallets, and bags.

Tanning Methods

Chrome Tanning

Chromium(III) sulfate is a very effective tanning agent. It is often used because it works well. Chromium(III) compounds are much safer than other types of chromium. When used in tanning, these compounds link up with the collagen in the skin. This makes the leather strong and stable.

The chemistry of this process is complex. Different chemicals are added to control how the chromium links with the collagen. This helps the chromium get deep into the skin fibers.

Before adding the chromium, the skin must be very acidic. This helps the chromium get into the fibers. After the chromium has soaked in, the pH is raised again. This helps the chromium link with the collagen. This step is called basification. Raw chrome-tanned skins look grayish-blue. So, they are called "wet blue." Chrome tanning is much faster than vegetable tanning. It can take less than a day. This method makes stretchy leather, which is great for handbags and clothes.

After the chromium is applied, sodium bicarbonate is added to the bath. This raises the pH. This helps the chromium and collagen link together. The temperature is also slowly increased. This linking makes the leather very strong and resistant to shrinking in hot water. Chrome-tanned leather usually contains about 4 to 5% chromium.

Vegetable Tanning

Vegetable tanning uses tannins. These are natural chemicals found in the bark and leaves of many plants. Tannins stick to the collagen proteins in the hide. This makes the leather less likely to dissolve in water. It also helps it resist bacteria. This process also makes the hide more flexible. Common plants used include chestnut, oak, and hemlock. Hides are soaked for several weeks in vats with increasing amounts of tannin. Vegetable-tanned leather is not very flexible. It is used for luggage, furniture, belts, and other accessories.

Other Tanning Chemicals

"Wet white" is a term for leather made with other tanning methods. These methods produce an off-white colored leather. Like "wet blue," "wet white" is a semi-finished stage. It can be made using chemicals like aldehydes, aluminum, or titanium salts. People are researching these methods more. This is because they want to find safer options than chromium.

Natural Tanning

Sometimes, natural conditions can tan skin. For example, in bogs, the water is very acidic and cold. There is also little oxygen. These conditions can preserve and tan the skin of "bog bodies."

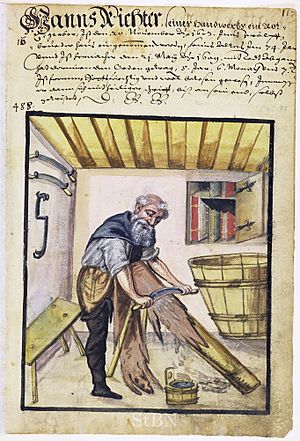

Tawing Method

Tawing is a method that uses alum and other aluminum salts. It often uses binders like egg yolk or flour. The hide is soaked in a warm solution of alum and salts. This makes the hide more flexible, stretchy, and soft. Then, the hide is air-dried for several weeks. This helps it become stable.

Using only alum for tanning is not usually recommended. It can make the skin shrink and feel hard. If alum is put on fur, it can make the fur dull.

Finishing the Leather

After tanning, the leather can be finished in many ways. It might be waxed, rolled, or oiled. It can also be split, shaved, or dyed. This depends on what the final leather product will be used for.

Safety and the Environment

The tanning process uses chemicals and natural compounds. If these are not handled carefully, they can affect the environment. Chemicals like chromium and aldehydes are used in tanning. If not properly treated, wastewater from tanneries can have high levels of chemicals. These processes also use a lot of water and create waste.

Sometimes, if not managed well, chromium compounds used in tanning can change into a harmful form. This harmful form can be bad for health. It is important that waste from tanneries is treated properly. Some older tanning methods can create more hazardous wastewater. This is especially true in smaller tanneries in developing countries.

Organizations like the UN Leather Working Group help. They have rules to check how leather factories manage waste. They also look at energy use and how materials are traced. This helps make the tanning process safer for people and the planet.

Other Ways to Treat Hides

Untanned hides can be dried and made soft by rubbing and stretching them. They can also be treated with fat. However, if they get wet, they will go back to being rawhide unless treated again. Many Native Americans used this method for clothing.

Smoke tanning is another method. The smoke puts chemicals into the hide's cells. This helps the hide resist germs and water.

Related Processes

Leftover leather pieces were historically used to make glue. Tanners would let scraps of hides break down in water for months. Then, they would boil the mixture to make glue.

A tannery might also have a grindery. This was a place to sharpen knives and tools. Later, it might also sell tools and materials for shoemakers.

Scientists are also researching new ways to treat solid waste and wastewater from tanneries. This includes methods like anaerobic digestion.

See also

- Tanwater

- Leather production processes

| May Edward Chinn |

| Rebecca Cole |

| Alexa Canady |

| Dorothy Lavinia Brown |