Leather facts for kids

Leather is a strong material made from the skin of an animal. The skins of cows, pigs, and goats are often used. Sometimes, skins from snakes, alligators, crocodiles, or ostriches are used for special types of leather. Many everyday items like Shoes, bags, clothes, and balls are made from leather.

Contents

How Leather is Made

Making leather involves three main steps: preparing the hide, tanning, and crusting. Sometimes, a final step called surface coating is also added.

Preparing the Hide

This first step gets the animal hide ready for tanning. It can include processes like liming (soaking in lime), removing hair, deliming, degreasing, bleaching (making it lighter), and pickling (soaking in acid and salt).

Tanning the Leather

Tanning is the most important step. It changes the raw hide so it won't rot. It also makes the leather flexible when it dries. Raw hides become hard and stiff when dry, and they rot if they get wet again. Tanned leather stays flexible and doesn't rot when wet.

During tanning, hides are put into a large drum with a special liquid called "tanning liquor." The drum slowly turns, letting the liquid soak into the hide. After the liquid has soaked all the way through, chemicals are added to make the tanning material stick to the leather. This makes the leather stronger and more resistant to heat.

Crusting and Finishing

Crusting is the step where the leather is made thinner and softer. It often includes adding color. Chemicals used in this step are made to stay in the leather. Crusting ends with drying and softening the leather. It might also involve splitting, shaving, dyeing, or whitening.

Some leathers get a final "finishing" step. This can include oiling, brushing, buffing, coating, polishing, or adding patterns. Oiling leather, called currying, helps it resist water better. Regular oiling with things like mink oil or neatsfoot oil keeps leather soft and makes it last longer.

Different Tanning Methods

The chemicals used in the tanning liquid create different types of leather. Here are some common methods:

- Vegetable-tanned leather uses natural materials like tannins from tree bark. This is the oldest way to tan leather. It's usually soft and brown, with the exact shade depending on the materials. This type of leather doesn't do well in water; it can change color and shrink if it gets wet and then dries.

- Chrome-tanned leather was invented in 1858. It uses chromium salts. This leather is often called "wet blue" because of its pale blue color before it's dyed. This method is very fast, usually taking about one day. It's the most common way leather is made today. Chrome-tanned leather is softer and more flexible than vegetable-tanned leather. It also handles water better. However, there are some worries about the environment because chromium is a heavy metal.

- Aldehyde-tanned leather uses special compounds like glutaraldehyde. It's called "wet white" because of its light cream color. This is a popular "chrome-free" leather, often used for baby shoes and car interiors.

- Chamois leather is a type of aldehyde tanning. It's very soft, porous, and can soak up a lot of water. It's made using marine oils, like cod oil.

- Brain tanned leathers are made using a lot of effort. They use oils from animal brains, like deer or buffalo. This leather is known for being super soft and easy to wash.

- Alum leather uses aluminium salts mixed with things like flour and egg yolk. This process is actually called "tawing," not true tanning. If alum leather is soaked in water for too long, it can turn back into raw hide.

Types of Leather

Leather comes in different qualities or "grades":

- Top-grain leather includes the strong outer layer of the animal hide. This part has very tight fibers, making it durable.

- Full-grain leather is the best quality. It includes the entire outer layer without any changes to its surface. Instead of wearing out, it develops a nice shine over time, called a patina. Furniture and shoes are often made from full-grain leather.

- Corrected grain leather has its surface treated to look more even. This usually means sanding away any flaws, then dyeing and adding a pattern to the surface.

- Nubuck is top-grain leather that has been lightly sanded on the outside. This gives it a soft, velvet-like feel.

- Split leather is made from the inner part of the hide after the top-grain layer has been removed. This part is often used to make suede. Split leather can also have a plastic layer added to make it look like top-grain leather. This is called bicast leather.

- Patent leather is leather with a very shiny, high-gloss finish. This is done by adding a special coating. The first way to mass-produce patent leather was developed in 1818 using a linseed oil-based coating. Today, it usually has a plastic coating.

- Bonded leather is also called reconstituted leather. It's made from shredded leather scraps that are glued together with plastic onto a fabric mesh. The amount of real leather in it can be anywhere from 10% to 90%.

Leather from Other Animals

Most leather today comes from cattle, but many other animal skins are used too.

Horse hides make very strong leather. Shell cordovan is a special horse leather known for its shiny finish and how it resists creasing. Lamb and deerskin are used for soft leather in more expensive clothes. Deer and elkskin are common for work gloves and indoor shoes. Pigskin is used for clothes and saddle seats. Leather can also come from buffalo, goat, ox, and yak.

Skins from reptiles like alligator, crocodile, and snake are known for their unique patterns. This has led to these animals being hunted and farmed for their skins.

Kangaroo leather is used for items that need to be strong and flexible. It's often used for bullwhips. Some motorcyclists like kangaroo leather for their motorcycle gear because it's light and resists scrapes. Kangaroo leather is also used for falconry equipment, soccer shoes, and boxing speed bags.

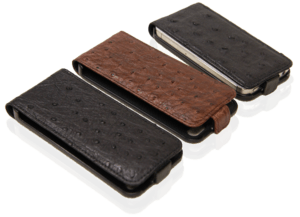

Ostriches were first raised for their feathers in the 1800s. Now, they are also popular for their meat and leather. Ostrich leather has a special "goose bump" look from where the feathers grew. It's used for many things, including furniture, shoes, car parts, and clothes.

In Thailand, stingray leather is used for wallets and belts. Stingray leather is very tough and strong. It's often dyed black and has tiny round bumps that are usually dyed white to stand out. Stingray rawhide is also used for grips on some swords. It's also used in motorcycle racing gloves because it's very resistant to scrapes in case of an accident.

Images for kids

See also

In Spanish: Cuero para niños

In Spanish: Cuero para niños

| Sharif Bey |

| Hale Woodruff |

| Richmond Barthé |

| Purvis Young |