Ball screw facts for kids

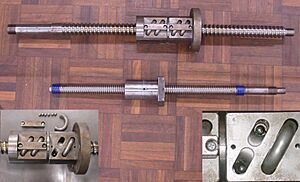

A ball screw is a special mechanical part that turns spinning motion into straight-line motion. Think of it like a very precise screw and nut, but instead of the nut sliding directly on the screw, it rolls on tiny ball bearings. This design helps it move with very little friction. Ball screws are super accurate and can handle heavy pushing or pulling forces easily. They are used in places where things need to move very precisely.

Contents

How Ball Screws Work

Ball screws are very efficient because they have low friction. This means they waste less energy compared to other types of screws. A typical ball screw can be 90% efficient! This also helps them last a long time and need less oil.

Stopping Wiggle and Wobble

One great thing about ball screws is that they can reduce or even stop "backlash." Backlash is like a small wiggle or looseness between the screw and its nut. Imagine trying to draw a straight line with a wobbly ruler – it's hard! Ball screws can be made so there's no wiggle at all. This is super important for machines that need to be very exact, like those used to make computer parts.

Why They Can't Be Hand-Cranked

Because ball screws are so efficient, they can sometimes be "back-driven." This means if you push on the nut, the screw might start spinning on its own. This is usually fine for machines controlled by motors. But for things you move by hand, like some old machine tools, it could be dangerous. If you let go, the machine might move unexpectedly. Regular screws are safer for hand-powered tools because they don't back-drive easily.

How the Balls Return

The tiny balls inside a ball screw need a way to get back to the start of their path. If they didn't, they would just fall out! Different designs help the balls recirculate:

- An external ballnut uses a small tube to pick up balls and put them back.

- An internal-button ballnut has a special button that guides the balls to the next thread.

- An endcap return ballnut uses caps at the ends to direct balls through holes inside the nut.

These return paths often use smooth plastic parts to keep friction low.

Making Ball Screws

Ball screw shafts can be made in different ways.

- Rolling them is cheaper and faster, but they are less precise. These are good for general uses.

- For very high precision, ball screws are machined and then ground. This is a much more detailed process.

- The most precise ones are made with special machines, like those used for optical lenses. These are incredibly accurate, down to tiny fractions of a millimeter!

Ball screws are given "accuracy grades" from C0 (most precise) to C10 (less precise).

Where Ball Screws Are Used

Ball screws are used in many important places:

- Aircraft and missiles: They help move control surfaces, especially in modern "fly-by-wire" systems where computers control the plane.

- Cars: They are used in power steering systems to help you turn the wheels easily.

- Factories: You'll find them in machine tools, robots, and equipment that puts things together very precisely.

- Semiconductor manufacturing: High-precision ball screws are key in making computer chips.

- Space: A ball screw helps expand a part of the James Webb Space Telescope.

- Energy: They are planned for use in new types of nuclear reactors, like the TerraPower Natrium Reactor, to control parts called Control rods.

Similar Systems

Another type of linear movement system is the threadless ballscrew. This design uses rolling rings around a smooth rod. It's different because it doesn't have threads, and it's very good at avoiding backlash.

See also

- Ball spline

- Jackscrew

- Leadscrew

- Linear actuator

- Linear-motion bearing

- Recirculating ball

- Roller screw

| Percy Lavon Julian |

| Katherine Johnson |

| George Washington Carver |

| Annie Easley |