Bead facts for kids

A bead is a small object with a hole in it. This hole lets you string beads together, like on a necklace or bracelet. Beads can be made from many different things, such as wood, glass, and even shiny gemstones.

Did you know the oldest beads found are over 100,000 years old? Ancient Egyptians used stone beads in their kings' graves. Clay beads were also very popular and often painted with cool patterns, just like their pots!

Making beads from clay is a fun and easy skill. You can create almost any design you can imagine!

For a long time, both men and women wore beads. As far back as 5000 BC, people valued wearing strands of shells, stones, teeth, and bones. Ancient trade ships, like those from Phoenicia, carried beads across the world, including to and from Egypt, starting around 2500 BC. This means beads have been around for a very long time!

Today, there are many kinds of beads, like silver beads, stone beads, and sparkling crystal beads. Stringing beads on wire is a popular way to make jewelry like bracelets, necklaces, and anklets. In Japan, bead making became very popular when Crown Princess Masako made her own crystal necklace. Bead art shows happen every November, where bead lovers show off their amazing creations and often start new trends!

Contents

Types of Beads

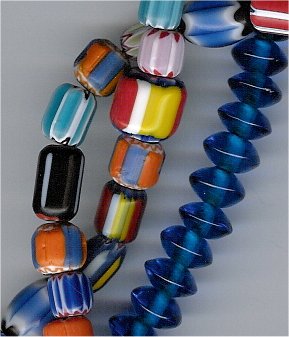

Beads can be sorted into different groups. We can group them by what they are made of, how they are made, where or when they came from, the patterns on them, or their general shape. Sometimes, a bead might fit into several groups at once, like millefiori or cloisonné beads.

What Beads Are Made Of

Beads can be made from many different materials. The very first beads were made from natural things that were easy to find, drill, and shape. As people learned to work with harder materials, they started using those too. Nowadays, we also use man-made materials.

In modern times, the most common bead materials are wood, plastic, glass, metal, and stone.

Natural Materials

Beads are still made from many natural things. Some come from plants or animals (like bone or wood), and others come from minerals (like stones or metals). Sometimes, these natural materials are treated to make them look even better, like adding color with dyes.

Natural materials from plants or animals include bone, coral, animal horn, ivory, seeds (like tagua nuts), animal shells, and wood. For most of history, pearls were very special because they were rare. Now, with modern pearl farming, they are much more common. Amber and jet are also natural materials that come from ancient fossilized tree resin.

Natural materials from minerals include different kinds of stones, from precious gemstones to common rocks, and metals. Only a few precious metals like gold are found in pure forms. Other metals are purified or found as natural mixtures.

Man-Made Materials

The oldest man-made materials used for beads are ceramics, like pottery and glass. Beads were also made from old metal mixtures like bronze, but these often don't last as long because they can rust.

Many types of glass are used for beads today. Some glass beads, like lead crystal beads, have a special ingredient that makes them extra sparkly. Other glass beads get their names from how they are made or their patterns.

Small, colorful plastic beads can be placed on a pegboard to make designs. Then, you can melt them together with a clothes iron. You can also string them into necklaces or bracelets. These beads come in many colors, some even glow in the dark! Plastic toy beads were first made in Sweden in 1958. The idea of using a pegboard to make designs was invented in the 1960s. It was first used as therapy for older people, but soon became a popular toy for kids.

How Beads Are Made

Modern beads are usually shaped by carving or pouring liquid material into molds. Sometimes, special metalworking or glassworking skills are used. Often, a mix of different techniques and materials is used, like in cloisonné beads.

Glass Beads

Most glass beads are "pressed glass." This means hot, melted glass is poured into molds to create the desired shape. Most plastic beads are made this way too.

Some glass and crystal beads are more expensive because they are carefully cut into precise shapes. This used to be done by hand, but now machines do most of this work.

"Fire-polished" beads are a cheaper option. First, the glass is poured into round molds. Then, they are shaped with a grinding wheel. After that, the beads are briefly heated again to melt the surface. This makes them smooth and shiny, like they've been polished by fire!

Special Glass Techniques

There are special ways to make glass beads that give them unique looks.

Sometimes, a large block of glass is made and then carved into smaller beads, just like stone. Other times, glass artists make beads one by one by melting and shaping glass with a torch.

Many glass beads are made by fusing different pieces of glass together. Dichroic glass beads have a thin, shiny layer of metal between layers of glass, giving them a cool, color-changing effect. Fibre optic glass beads have a special shimmer that seems to move.

There are also ways to fuse many small glass rods together to make colorful patterns. This creates millefiori beads or chevron beads. Furnace glass beads have a colorful design inside a clear outer layer, which is then heated in a furnace.

A simpler way to make millefiori beads is to cut thin slices from long, patterned glass rods. These slices are then melted onto the surface of a plain glass bead.

Images for kids

-

Merovingian bead

-

Carved Cinnabar lacquer beads

-

Bead, depicting a pomegranate, dated to the Assyrian Empire of the 8th century BCE.

-

Antique Celtic pearl, Gallic, stone

See also

In Spanish: Abalorio para niños

In Spanish: Abalorio para niños

| Percy Lavon Julian |

| Katherine Johnson |

| George Washington Carver |

| Annie Easley |