Dry Dock Complex (Detroit, Michigan) facts for kids

Quick facts for kids |

|

|

Dry Dock Engine Works-Detroit Dry Dock Company Complex

|

|

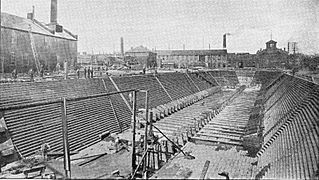

Dry Dock No. 2 (now filled with water) is in the foreground; the Engine Works complex is in the background. Image was taken previous to the redevelopment of the building.

|

|

| Location | 1801–1803 and 1900 Atwater St., Detroit, Michigan |

|---|---|

| Built | 1892, 1902, c. 1910s |

| Architect | Berlin Iron Bridge Co. |

| NRHP reference No. | 09000680 |

| Added to NRHP | September 3, 2009 |

The Dry Dock Complex is a group of six connected buildings. They are located at 1801–1803 Atwater Street in Detroit, Michigan. There are also parts of a nearby dry dock at 1900 Atwater Street. The buildings at 1801-1803 Atwater are also known as the Globe Trading Company Building. In 2015, the Michigan Department of Natural Resources opened them as the Outdoor Adventure Center.

This complex is important because it was a major place for building and fixing ships. The oldest building, a machine shop from 1892, is special. It was one of the first industrial buildings to use a full steel frame to hold up the building. Its outer walls were made of brick and windows, but they didn't carry the building's weight. The complex was added to the National Register of Historic Places in 2009. This means it's a very important historical site. In 2012, money was given to fix up the complex. It is now a part of Detroit's riverfront area.

Contents

History of the Dry Dock Complex

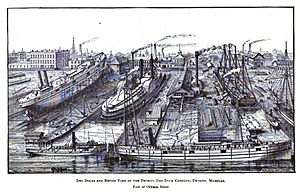

The Dry Dock Engine Works-Detroit Dry Dock Company Complex includes parts of two companies. These companies were once separate. They were called the Dry Dock Engine Works and the Detroit Dry Dock Company. They joined together in 1899.

Detroit Dry Dock Company

In the 1840s, Captain Stephen R. Kirby started a company that built ships. It was in Cleveland, Ohio. By 1852, he moved his business to Saginaw, Michigan. In 1870, Kirby's son, Frank, joined the company. He was an engineer and became the main designer. Frank Kirby became a very successful ship designer. He designed two ships that are now famous landmarks: the Columbia and the Ste. Claire. In 1872, the Kirby family's company bought a shipyard in Wyandotte, Michigan.

In 1852, another company called Campbell, Wolverton and Company opened. They fixed ships on the Detroit River. In 1860, this company built a 260-foot-long dry dock. A dry dock is a special area where ships can be brought out of the water for repairs. They built their first steamship in 1867.

In 1877, the company changed its name to the Detroit Dry Dock Company. Around the same time, they bought the Kirby family's shipbuilding company. Also in the late 1870s, a powerful businessman named James McMillan became interested in shipbuilding. He bought parts of the Detroit Dry Dock Company. By 1890, McMillan was the president of this company. By 1892, he was also president of the nearby Dry Dock Engine Works.

Dry Dock Engine Works

The Dry Dock Engine Works made engines for ships. It was started in 1866 by William Cowie, Edward Jones, and Robert Donaldson. Their shop was on Atwater Street, across from the dry dock company. Over time, they bought more land around their shop.

Their main product was marine engines. They made 129 engines between 1867 and 1894. But they also made other engines and mining equipment. In 1883, they bought a boiler shop. This allowed them to make even more products.

The Dry Dock Engine Works is famous for another reason. It was an early workplace for Henry Ford. He worked there as an apprentice machinist from 1880 to 1882. His work with steam engines here helped him later think about putting an engine into a carriage. This idea led to the first automobiles.

The Dry Dock Engine Works and the Detroit Dry Dock Company always worked closely. In the 1870s, the Engine Works sold many of its engines to the Dry Dock Company. By the 1890s, almost two-thirds of their engines went to them. The same people, like Frank Kirby, John Owen, and James McMillan, owned parts of both companies. By 1892, James McMillan was president of both. Around this time, the oldest buildings still standing today were built. These include the machine shop and Dry Dock No. 2.

Joining Together: Detroit Shipbuilding Company

Even though they had the same leader, the two companies were separate until 1899. That year, the Dry Dock Engine Works, the Detroit Dry Dock Company, and another company joined. They formed the Detroit Shipbuilding Company. This new company was part of a bigger company called the American Shipbuilding Company.

This merger created a very large company. In 1900, the Detroit Shipbuilding Company had 1337 employees. It was the fourth-largest employer in Detroit. A few years later, in 1902, they built two more buildings that are still here: the foundry and the industrial loft building. Around the 1910s, three more buildings were added. These completed the complex as we see it today.

Shipbuilding continued in Detroit and Wyandotte through the 1920s. Many ships were built during World War I (1917-1919). But business slowed down. In 1920, the Wyandotte shipyard closed. In 1924, the last two ships were finished in the Detroit yards. The Detroit Shipbuilding Company stopped all operations in 1929.

What Happened After Shipbuilding

After the shipbuilding company closed, the property changed owners many times. In the early 1930s, it was used by a cabinet shop and a stove maker. In 1935, the Detroit Edison Company bought the property. They used the engine-building plant to fix appliances in the 1950s and 60s.

By 1968, the Globe Trading Company moved in. They sold machinery. In 1981, Detroit Edison sold the property to Globe. Later, the property was left empty. By 2002, the city of Detroit owned it.

Redevelopment

In 2006, a plan was announced to fix up the buildings. The idea was to create apartments and shops. To help with this, the city received a grant in 2007. This money from the Environmental Protection Agency helped clean up the old building.

However, the economy slowed down in 2008-2009. The plans changed from apartments to rental units. The project was going to get money from the Department of Housing and Urban Development. It also got money from historic tax credits. These credits were possible because the complex was listed on the National Register of Historic Places in 2009.

Instead of housing, the Michigan Department of Natural Resources started renovating the building in 2013. They turned it into the Outdoor Adventure Center. Some parts of the old buildings were taken down for this. The center opened in 2015.

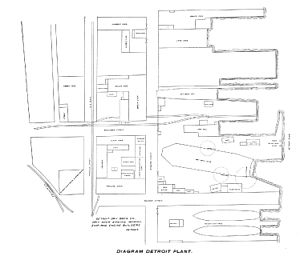

Buildings and Structures

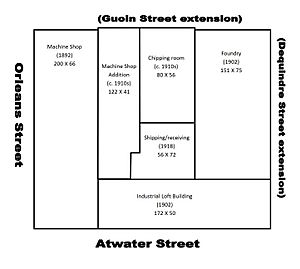

The Dry Dock Engine Works started making engines on Atwater Street in 1867. But the first buildings they used were replaced later. The buildings we see today were built between 1892 and 1919. The Detroit Dry Dock Company also started building ships in this area around 1852. Their older dry docks are no longer there. Today, six buildings and Dry Dock No. 2 still remain.

Detroit Dry Dock Co. Dry Dock No. 2 (1892)

In 1892, the Detroit Dry Dock Company built a new dry dock. It was near Orleans Street. This dry dock, called Dry Dock No. 2, was 378 feet long. It was 20.5 feet deep below the water line. It was 91 feet wide at the top and 55 feet wide at the bottom. More than two thousand poles were put into the ground to support it.

The dock could be filled with water in twenty minutes. It could be pumped dry in about ninety minutes. It was big enough for any ship on the Great Lakes at that time. It could even hold ships that were fully loaded.

A special monument is located at the north end of the dry dock. It has a sculpture showing the dry dock and a ship called the Pioneer.

- Dry Dock No. 2, contemporary and historical images

Dry Dock Engine Works Machine Shop (1892)

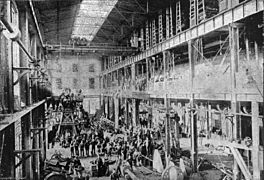

Also in 1892, Detroit Dry Dock built a machine shop. It was at the corner of Atwater and Orleans. The Berlin Iron Bridge Company designed and built it. This company was from Connecticut. The building was special because it had a strong steel frame. This frame held up the building's weight. The brick outer walls, called curtain walls, did not carry weight. This was a new way to build at the time.

Description

The machine shop is 200 feet long and 66 feet wide. It is 48 feet tall to the top of the wall. A roof monitor adds another 10 feet to the height. The building has thirteen sections. Inside, it has a wide main area and a smaller side area.

The walls at each end of the building rise above the roof. They are topped with limestone. The west side originally had two windows per section. These windows were changed between 1912 and 1932. The building also had two large doors on the west side. These have since been filled with bricks. The roof is held up by a series of supports. A 13-foot-wide roof monitor runs along most of the roof. This monitor was originally made of glass.

Background

The 1892 machine shop was built using the newest ideas for factory buildings. It used electric-powered machines and an electric overhead crane. The building was tall and wide with an open space inside. This design allowed the crane to move easily. The company even wrote about how great the open space was. They liked the "great advantages of light and air" from the skylight and windows.

The open space was possible because of the new way it was built. Steel frame construction started in the 1880s in Chicago. The first building fully supported by a steel frame was the 1889 Rand McNally Building. The steel frame meant the outer walls didn't need to support the building's weight. They just covered the frame like a curtain. The Berlin Iron Bridge Company was good at building with steel. They started designing steel-framed industrial buildings in the late 1880s.

Significance

The machine shop is an early example of an industrial building. It was completely supported by a strong steel frame. Its outer walls were just a curtain around the structure. This building might have been the first of its kind in Detroit.

The design used by the Berlin Iron Bridge Company was a mix of old and new. The steel frame held up the building completely. But the brick outer walls looked like traditional heavy brick walls. The windows were standard size and arranged in the usual way.

This building gave the Dry Dock Engine Works the best of both worlds. It had the open inside space of a steel frame building. It also had the solid, traditional look of a brick building. The brick helped keep it warm in winter. The many windows let in a lot of light. This building shows how industrial architecture changed from old styles to new steel framing.

Experts Eric J. Hill and John Gallagher say this building is "perhaps the most important surviving nineteenth-century industrial building in Detroit."

Machine Shop photo gallery

- Machine Shop, Contemporary and historical images

Industrial Loft Building and Foundry (1902)

In 1902, the company built two more structures: the Industrial Loft Building and a foundry. The Industrial Loft Building was along Atwater Street. The foundry was behind it, completing the block.

Foundry

The foundry is 151 feet long and 75 feet wide. It stands 50 feet high. A roof monitor adds another 14 feet to its height. The building has seven sections. It has a large main area and a smaller side area.

Like the machine shop, the foundry has a steel frame. The steel frame holds up the building. The brick walls do not carry weight. The inside sections are very tall. This allowed for an overhead crane to move materials.

The foundry building was used as a foundry for only about ten years. Around the 1910s, the company built a new foundry. This building was then used as an erecting shop. Later, part of the building was turned into a loading dock.

Industrial Loft Building

At the same time as the foundry, the Detroit Shipbuilding Company also built a three-story loft building. This building was on Atwater Street. It was 172 feet long, 50 feet wide, and 55 feet high.

The first floor originally had a blacksmith's shop and offices. The second floor had a pattern shop and tool room. The third floor had engineering offices and storage. Two narrow driveways went through the first floor to a courtyard. These driveways were later filled with bricks. Other changes were made to the outside over time.

Like the machine shop and foundry, the loft building had a steel frame. It also had brick curtain walls. The steel frame supported the floors and roof. The steel frame was inside the building, not covered by the brick.

- Foundry and Industrial Loft Building Interiors

Machine Shop Addition, Chipping Room, and Shipping/Receiving (c. 1910s)

Between 1910 and 1919, three more buildings were constructed. They filled the space between the 1892 machine shop and the 1902 foundry.

Machine Shop Addition

The machine shop addition is a steel-framed building. It is 122 feet long, 41 feet wide, and 43 feet high. A roof monitor adds another 4 feet to its height. It was built next to the 1892 machine shop. The brick wall of the old machine shop was removed to connect the two spaces. The north wall had a large steel-framed window. Part of it is now bricked in.

The inside of this addition was originally a large, open space. It had an overhead crane, like the main machine shop. But after 1922, a wooden second floor was added inside.

Chipping Room

Later, a chipping room was built. It was located at the north end of the block. This room was where rough spots on metal castings were smoothed out. This building also has a steel frame. It shares its support columns with the buildings next to it. The chipping room is 80 feet long and 56 feet wide. It was built in two parts. Much of the north side originally had steel-framed windows. These have since been covered.

Shipping/Receiving

In 1918, the company built a shipping/receiving building. It was in the center of the complex, in what used to be an open courtyard. This building has two stories and a steel frame. It is 5 feet by 72 feet. The first floor was for shipping and receiving goods. It could be reached from Atwater Street through the industrial loft building. The second floor was used as a stockroom. A roof monitor provided light for the second floor. The first floor needed artificial lights because it was fully enclosed.

| Mary Eliza Mahoney |

| Susie King Taylor |

| Ida Gray |

| Eliza Ann Grier |