Henry Ford facts for kids

Quick facts for kids

Henry Ford

|

|

|---|---|

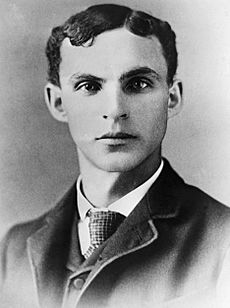

Photo by Fred Hartsook, c. 1919

|

|

| Born | July 30, 1863 |

| Died | April 7, 1947 (aged 83) Dearborn, Michigan, U.S.

|

| Resting place | St. Martha's Episcopal Church Cemetery, Detroit, Michigan, U.S. |

| Occupation | Engineer, industrialist, philanthropist |

| Years active | 1891–1945 |

| Known for | Founding and leading the Ford Motor Company Pioneering a system that launched the mass production and sale of affordable automotives to the public |

| Title | President of Ford Motor Company (1906–1919, 1943–1945) |

| Political party |

|

| Spouse(s) |

Clara Jane Bryant

(m. 1888) |

| Children | Edsel Ford |

| Signature | |

Henry Ford (July 30, 1863 – April 7, 1947) was an American engineer and businessman. He started making cars in 1896 and founded the Ford Motor Company.

He created the idea of an assembly line. This is a system where each worker does one small part of making something. This idea made it possible to produce cars in huge numbers. Many factories around the world still use this method today. It was very new at the time and helped him make many cars quickly and at a lower price than other companies.

As the main owner of the Ford Motor Company, he became one of the richest and most famous people in the world. He is known for "Fordism". This means making many affordable goods while paying workers well. Ford also helped start the idea of a five-day work week.

After his son Edsel passed away in 1943, Henry Ford took control of the company again. But he was not well enough to make big decisions. He handed the company over to his grandson Henry Ford II in 1945. Henry Ford died in 1947. He left most of his money to the Ford Foundation and the company to his family.

Contents

Early Life and Inventions

Henry Ford was born on July 30, 1863, on a farm in Springwells Township, Michigan. His father was William Ford, and his mother was Mary Ford. Henry had four siblings. He finished eighth grade at a one-room school. He never went to high school.

When he was 12, his father gave him a pocket watch. By age 15, Ford was known for fixing watches for friends and neighbors. He would take them apart and put them back together many times.

Ford was very sad when his mother died in 1876. His father wanted him to take over the farm, but Henry did not like farm work. He later wrote, "I never had any particular love for the farm—it was the mother on the farm I loved."

In 1879, Ford left home to work as a machinist in Detroit. He worked for James F. Flower & Bros. and later for the Detroit Dry Dock Co. In 1882, he returned to the family farm. There, he became good at using a steam engine. He was later hired to fix these engines for Westinghouse.

Ford said two important things happened when he was 12. He got the watch, and he saw a road engine. This was the first vehicle he had ever seen that was not pulled by horses. In his workshop, Ford built a "steam wagon" and a steam car. But he felt steam was not good for light vehicles.

In 1885, Ford fixed an Otto engine. By 1887, he built his own four-cycle engine. In 1890, he started working on a two-cylinder engine.

Ford completed his first motor car in 1892. He said it was running well enough by the spring of 1893. He drove it about 1,000 miles between 1895 and 1896. He then started building a second car in 1896. He built three cars in his home workshop.

Marriage and Family Life

Henry Ford married Clara Jane Bryant on April 11, 1888. To support themselves, he farmed and ran a sawmill. They had one child together, a son named Edsel Ford (1893–1943).

Building a Car Company

In 1891, Ford became an engineer with the Edison Illuminating Company of Detroit. He was promoted to Chief Engineer in 1893. This gave him enough time and money to work on his gasoline engine experiments.

These experiments led to his first self-propelled vehicle in 1896. He called it the Ford Quadricycle. He test-drove it on June 4. After many tests, Ford thought of ways to make the Quadricycle better.

In 1896, Ford met Thomas Edison. Edison liked Ford's car experiments. With Edison's encouragement, Ford designed and built a second vehicle in 1898. With money from William H. Murphy, a Detroit lumber businessman, Ford left the Edison Company. He started the Detroit Automobile Company on August 5, 1899. However, the cars made were not as good as Ford wanted, and they cost too much. The company did not do well and closed in January 1901.

With help from C. Harold Wills, Ford designed and raced a 26-horsepower car in October 1901. It won! Because of this success, Murphy and others formed the Henry Ford Company in November 1901. Ford was the chief engineer. In 1902, Ford left the company that had his name. It was then renamed the Cadillac Automobile Company.

Ford then worked with former racing cyclist Tom Cooper. They built a powerful 80-horsepower race car called the "999." Barney Oldfield drove it to victory in a race in October 1902. Ford also got support from Alexander Y. Malcomson, a coal dealer. They started a partnership called "Ford & Malcomson, Ltd." to make cars. Ford began designing a low-cost car.

Starting the Ford Motor Company

Sales were slow, and they faced problems. So, Malcomson brought in more investors. He also convinced the Dodge Brothers, who supplied parts, to accept a share of the new company. Ford & Malcomson became the Ford Motor Company on June 16, 1903. They started with $28,000.

Henry Ford showed off a new car on the ice of Lake St. Clair. He drove one mile in 39.4 seconds, setting a new land speed record. This car was named "999" after a fast train. Race driver Barney Oldfield drove it around the country, making the Ford name famous. Ford also supported the Indianapolis 500 race.

The Famous Model T

The Model T first came out on October 1, 1908. It had the steering wheel on the left, which other car companies soon copied. The engine and transmission were fully covered. The car was simple to drive and easy and cheap to fix.

It was very affordable, costing $825 in 1908. The price dropped every year. By the 1920s, most American drivers learned to drive on a Model T.

Ford created a big advertising effort in Detroit. He made sure newspapers had stories and ads about the new car. Ford's network of local dealers made the car popular everywhere. These dealers became rich and helped make cars popular in general. Local car clubs started to help new drivers. Ford wanted to sell to farmers, who saw the car as a tool for their work.

Sales grew very fast. In 1913, Ford started using moving assembly belts in his factories. This greatly increased how many cars they could make. While Ford is often given credit for the idea, his employees Clarence Avery, Peter E. Martin, Charles E. Sorensen, and C. Harold Wills developed it.

By 1918, half of all cars in the United States were Model Ts. All new cars were black. Ford famously wrote, "Any customer can have a car painted any color that he wants so long as it is black." Before the assembly line, Model Ts came in other colors. But black paint dried faster, which was important for the assembly line. The Model T was made until 1927. Over 15 million were built. This record lasted for 45 years.

Henry Ford gave the job of president of Ford Motor Company to his son Edsel Ford in December 1918. But Henry still made the final decisions. He even sometimes changed his son's choices. Henry Ford wanted full control of the company. He bought out all the other investors, so his family owned the company completely.

In 1922, Ford bought Lincoln Motor Co.. This company made luxury cars. Henry Ford was not as interested in luxury cars as his son Edsel was. Edsel wanted Ford to make more expensive cars.

By the mid-1920s, General Motors was becoming the top car maker in America. GM offered cars for "every purse and purpose." This was different from Ford, who focused on low-cost cars. Henry Ford did not want to replace the Model T, which was now 16 years old. But sales were dropping. So, Ford had to agree to make a new model. Production stopped for 18 months while they built a huge new factory for the new car.

The Model A and Later Cars

By 1926, the Model T's slow sales convinced Ford to make a new car. He worked hard on the engine and other parts. He let his son Edsel design the car's body. A team of engineers did most of the design work for the Model A. Ford watched them closely and gave them ideas. Edsel also convinced his father to include a modern transmission.

The new car was the successful Ford Model A. It came out in December 1927. Over four million were made by 1931. After this, Ford started changing its car models every year, like General Motors.

In the 1930s, Ford finally agreed to offer payment plans for cars. The Ford-owned Universal Credit Corporation became a big car financing company. Henry Ford was slow to adopt some new car features like hydraulic brakes and all-metal roofs. These were not on Ford cars until 1935–36.

However, in 1932, Ford released the flathead Ford V8. This was the first affordable eight-cylinder engine. It made Ford known for powerful cars, good for hot-rodding.

Ford did not believe in accountants. He built one of the world's largest fortunes without ever having his company's finances officially checked. Without an accounting department, Ford did not know exactly how much money was coming in or going out. The company's bills were reportedly guessed by weighing them! Ford did not become a publicly traded company until 1956.

Also, because Edsel insisted, Ford launched Mercury in 1939. This was a mid-range car brand to compete with Dodge and Buick.

Ford's Ideas on Workers

The Five-Dollar Wage

Henry Ford was a leader in "welfare capitalism." This was a way to make workers' lives better. It also helped reduce how often workers left their jobs. Ford wanted to hire and keep the best workers.

In 1914, Ford surprised the world by offering a $5 per day wage. This was more than double what most of his workers earned. A newspaper said the news "shot like a blinding rocket." This move was very good for the company. Instead of workers constantly leaving, the best mechanics came to Ford. This made production higher and lowered training costs.

Ford's policy showed that paying employees more would let them buy the cars they were making. This would help the economy. He saw the higher wages as sharing profits and rewarding good, productive workers.

The Five-Day Workweek

Ford also started a shorter workweek in 1926. The decision was made in 1922 to have six 8-hour days. But in 1926, it was announced as five 8-hour days, making a 40-hour week. On May 1, 1926, Ford Motor Company factory workers switched to a five-day, 40-hour workweek. Office workers followed in August.

Ford wanted to increase how much work got done. He expected workers to try harder in exchange for more free time. Ford also believed that having good free time was good for business. It gave workers more time to buy and use more goods. Ford said, "It is high time to rid ourselves of the notion that leisure for workmen is either 'lost time' or a class privilege."

Views on Labor Unions

Ford was strongly against labor unions. He believed they were too controlled by leaders who might not help workers in the long run. He thought unions wanted to limit how much was produced to create more jobs. But Ford believed that making more things was necessary for everyone to be successful.

He thought that if companies made things more efficiently, some jobs might change. But he believed this would help the economy grow and create new jobs elsewhere. Ford also thought that good managers would treat their workers well because it would help their business.

To stop unions from forming, Ford put Harry Bennett in charge of his Service Department. Bennett used different ways to stop union organizing. In 1937, Bennett's security men beat members of the United Automobile Workers (UAW). This event became known as The Battle of the Overpass.

In the late 1930s and early 1940s, Edsel, who was president, thought Ford should work with the unions. But Henry Ford, who still had the final say, refused. For several years, he kept Bennett in charge of dealing with the unions.

Ford Motor Company was the last major car maker in Detroit to recognize the UAW. This was despite pressure from other companies and the U.S. government. In April 1941, a strike by the UAW closed the River Rouge Plant. Henry Ford was very upset. His wife, Clara, told him she would leave him if he destroyed the family business. Ford listened to his wife. Overnight, Ford Motor Company changed from being the most stubborn company to having the best union contract. The contract was signed in June 1941.

Ford and Airplanes

Like other car companies, Ford started making airplanes during World War I. They built Liberty engines. After the war, they went back to making cars. But in 1925, Ford bought the Stout Metal Airplane Company.

Ford's most successful airplane was the Ford 4AT Trimotor. People often called it the "Tin Goose" because it was made of corrugated metal. It used a new metal called Alclad. This metal was strong and did not rust easily. The Trimotor first flew on June 11, 1926. It was the first successful U.S. passenger airplane. It could carry about 12 passengers. The Smithsonian Institution has honored Ford for his impact on the aviation industry. 199 Trimotors were built before production stopped in 1933. This was because of low sales during the Great Depression.

Ford During Wartime

Ford did not like war. He thought it was a terrible waste. In 1915, he agreed to pay for a "Peace Ship" to Europe, where World War I was happening. He led 170 other peace activists. Ford talked to President Woodrow Wilson about the trip, but he did not get government support. His group went to neutral countries to meet with peace activists. Ford left the ship when it reached Sweden.

Ford believed that war hurt businesses and slowed down economic growth. He said that if every company made the best products at the lowest prices, it would help prevent wars. He thought most businesses wanted to avoid wars and instead make useful goods, hire workers, and earn steady profits.

Ford's factories in Britain made Fordson tractors to help with food supply. They also made trucks and warplane engines. When the U.S. joined the war in 1917, Ford's company became a major supplier of weapons. They made Liberty engines for warplanes and anti-submarine boats.

In 1918, President Woodrow Wilson asked Ford to run for a U.S. Senate seat in Michigan. Wilson thought Ford could help support his idea for the League of Nations. Ford ran and almost won.

Willow Run Factory

Before the U.S. entered World War II, President Roosevelt asked for a "Great Arsenal of Democracy." In response, Ford built a huge new airplane factory called Willow Run near Detroit. Construction started in 1941. It began making parts for B-24 bombers in May 1942. The first complete B-24 came off the line in October 1942.

At 3.5 million square feet, it was the largest assembly line in the world at the time. At its busiest in 1944, the Willow Run plant made 650 B-24s each month. By 1945, Ford was finishing each B-24 in just eighteen hours. One plane rolled off the assembly line every 58 minutes. Ford made 9,000 B-24s at Willow Run. This was half of all the B-24s made during the war.

Changes in Leadership

When Edsel Ford died of cancer in May 1943, Henry Ford took over as president again. But Henry was almost 80 years old and not well. He had trouble making decisions. Other people started making choices for him. The company was run by a few top executives.

In 1945, the company was at risk of going bankrupt. Ford's wife Clara and Edsel's widow Eleanor told him he had to give control of the company to his grandson Henry Ford II. They said they would sell their shares, which were three-quarters of the company, if he refused. Henry Ford was very angry, but he had no choice. His grandson took over and immediately fired Harry Bennett.

Ford's Global Business

Ford believed in the United States being economically independent. His River Rouge Plant became the world's largest industrial complex. It made its own steel and other parts. Ford wanted to make a car from start to finish without needing foreign trade.

He also believed in expanding his company around the world. He thought that international trade and working together would lead to peace. He used the assembly line and the Model T to show this.

He opened Ford assembly plants in Britain and Canada in 1911. Soon, Ford was the biggest car maker in those countries. In 1912, Ford worked with Giovanni Agnelli of Fiat to open the first Italian car assembly plants. The first plants in Germany were built in the 1920s. Ford also opened plants in Australia, India, and France. By 1929, he had successful dealerships on six continents.

In 1929, Ford made a deal with the Soviets. He agreed to provide help for nine years to build the first Soviet automobile plant (GAZ). Ford sent his engineers to the Soviet Union to help set up equipment and train workers. Over a hundred Soviet engineers came to Ford's plants in Detroit to learn how to make cars. Ford said, "No matter where industry prospers... the more profit there will be for everyone, including us."

By 1932, Ford was making one-third of all the cars in the world. He set up many companies that sold or assembled Ford cars and trucks:

- Ford of Australia

- Ford of Britain

- Ford of Argentina

- Ford of Brazil

- Ford of Canada

- Ford of Europe

- Ford India

- Ford South Africa

- Ford Mexico

- Ford Philippines

Ford's ideas impressed Europeans, especially in Germany. They saw Ford's factories as a symbol of American success. They believed that Fordism showed how American capitalism worked. One German said, "Automobiles have so completely changed the American's mode of life that today one can hardly imagine being without a car."

In his book My Life and Work, Ford believed that if people could overcome greed and short-sightedness, then economic growth around the world would help everyone.

Car Racing and Ford

Ford was interested in car racing from 1901 to 1913. He started as both a car builder and a driver. Later, he hired other drivers. On October 10, 1901, he beat Alexander Winton in a race car called "Sweepstakes." This win helped him create the Henry Ford Company.

Ford entered special Model Ts in races. He finished first in a cross-country race in 1909 (though he was later disqualified). In 1911, his driver Frank Kulick set a speed record at the Detroit Fairgrounds.

In 1913, Ford tried to enter a Model T in the Indianapolis 500. But he was told the car needed to be much heavier. Ford left the race and soon stopped racing for good. He said he was not happy with the rules and was too busy making the Model T. He also did not think racing was a very useful activity.

In his book, Ford talked about racing as something he did only because people at the time thought it was the way to prove a car's worth. He did not agree. But he wanted his cars to be the best at racing if that was the measure of success. He cared more about making cars affordable, reliable, and efficient for everyone.

Even though he stopped racing, Ford made a big impact on the sport. He was inducted into the Motorsports Hall of Fame of America in 1996.

Later Life and Passing

When his son Edsel Ford died in May 1943, Henry Ford, who was elderly and unwell, decided to become president again. By this time, Ford was almost 80. He had suffered some health problems and was not mentally fit for such big responsibilities.

Most of the company directors did not want him as president. But for 20 years, he had always been in charge, even without an official title. So, the directors elected him. He served until the end of the war. During this time, the company started to lose a lot of money.

Because his health was failing, Ford gave the company presidency to his grandson Henry Ford II in September 1945. He then retired. Henry Ford died on April 7, 1947, at his home in Dearborn. He was 83 years old.

Thousands of people came to see his casket at Greenfield Village. Funeral services were held in Detroit. He was buried in the Ford Cemetery in Detroit.

Personal Interests and Hobbies

Henry Ford was a Freemason. He became a member in 1894. In 1940, he said, "Masonry is the best balance wheel the United States has."

In 1914, Ford published a book against smoking called The Case Against the Little White Slaver. It talked about the dangers of cigarette smoking. At that time, smoking was very common and not widely linked to health problems. So, Ford's views were unusual.

Interest in New Materials

Henry Ford was very interested in materials science and engineering. He liked using new steel alloys in his cars.

Ford was also interested in plastics made from farm products, especially soybeans. He worked with George Washington Carver on this. Plastics made from soybeans were used in Ford cars in the 1930s. They were used for parts like car horns and in paint. In 1942, Ford even patented a car made almost entirely of plastic. It weighed 30% less than a steel car and was said to be much stronger. It ran on grain alcohol instead of gasoline. However, this design was never widely used.

Ford was interested in engineered woods, like plywood. He also looked at corn as a fuel source and the uses of cotton. Ford helped create charcoal briquets under the brand name "Kingsford." His brother-in-law used wood scraps from the Ford factory to make them.

In 1927, Ford worked with Thomas Edison and Harvey Samuel Firestone. They started a research company in Florida to find a natural source of rubber.

Ford was a prolific inventor and received 161 U.S. patents.

Homes and Community Work

Ford had a vacation home in Fort Myers, Florida, next to Thomas Edison's home. He bought it in 1915 and used it until about 1930. Today, it is a museum.

He also had a vacation home in Richmond Hill, Georgia. This is now a private community. Ford bought a lot of land there. In 1936, he started building a beautiful mansion on the Ogeechee River. The house was made of brick and had air conditioning and an elevator. It was the center of social gatherings. Ford also helped the community by building a chapel and a schoolhouse. He hired many local people.

Saving American History

Ford was interested in "Americana." In the 1920s, he tried to turn Sudbury, Massachusetts, into a historical village. He moved a schoolhouse there and bought the historic Wayside Inn. This plan did not fully happen.

He then created Greenfield Village in Dearborn, Michigan. This village has many historic buildings that Ford collected. It might have inspired other historical villages. Around the same time, he started collecting items for his museum. The museum focused on practical technology. It opened in 1929 as the Edison Institute. The museum is still open today.

Famous Quotes from Henry Ford

- “Whether you think you can or you think you can't, you’re right.”

- “It has been my observation that people get ahead during the time that others waste.”

- “You can’t build a reputation on what you’re going to do.”

- “There is no failure except failure to serve one’s purpose.”

- “When everything seems to be going against you, remember that the airplane takes off against the wind, not with it.”

- “You can’t learn in school what the world is going to do next year.”

- “Quality means doing it right when no one is looking.”

- “A business that makes nothing but money is a poor business.”

- “Obstacles are those frightful things you see when you take your eyes off your goal.”

Honors and Recognition

- In December 1999, Ford was among 18 people on Gallup's List of Widely Admired People of the 20th Century.

- In 1928, Ford received the Franklin Institute's Elliott Cresson Medal.

- The United States Postal Service honored Ford with a 12¢ postage stamp (1965–1978).

- He was inducted into the Automotive Hall of Fame in 1946.

- In 1975, Ford was added to the Junior Achievement U.S. Business Hall of Fame.

- In 1985, he was inducted into the National Aviation Hall of Fame.

- He was inducted into the Motorsports Hall of Fame of America in 1996.

See also

In Spanish: Henry Ford para niños

In Spanish: Henry Ford para niños

- Capitalist peace

- Detroit, Toledo and Ironton Railroad

- Dodge v. Ford Motor Company

- Edison and Ford Winter Estates

- Arthur Constantin Krebs

- Ferdinand Porsche

- Ferdinand Verbiest

- Ford family tree

- John Burroughs

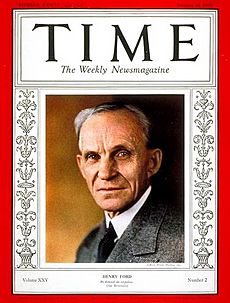

- List of covers of Time magazine (1920s)

- List of richest Americans in history

- List of wealthiest historical figures

- Outline of Henry Ford

- Preston Tucker

- Ransom Olds

- William Benson Mayo

| Toni Morrison |

| Barack Obama |

| Martin Luther King Jr. |

| Ralph Bunche |