Ford River Rouge complex facts for kids

|

Ford River Rouge complex

|

|

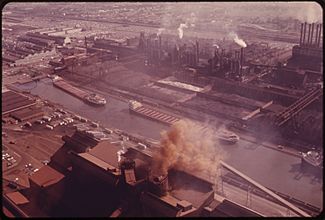

Aerial view of the Rouge complex in 1927

|

|

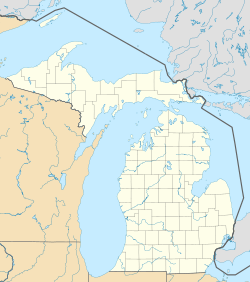

| Location | Dearborn, Michigan, United States |

|---|---|

| Area | 900 acres (360 ha) (landmarked area) |

| Built | 1917–1928 |

| Architect | Albert Kahn |

| Visitation | 148,000 (2017) |

| NRHP reference No. | 78001516 |

Quick facts for kids Significant dates |

|

| Added to NRHP | June 2, 1978 |

| Designated NHLD | June 2, 1978 |

The Ford River Rouge complex, often called the Rouge complex or just The Rouge, is a huge Ford Motor Company car factory. It's located in Dearborn, Michigan, right along the River Rouge.

Building this amazing factory started in 1917. When it was finished in 1928, it became the largest factory in the world! It was so big that it could turn raw materials into finished cars all in one place. This idea of having everything in one factory inspired other big factories around the world, like those in France, Russia, Germany, and South Korea.

The River Rouge complex was designed by a famous architect named Albert Kahn. Because of its special design and its important role in American industry, it was named a National Historic Landmark District in 1978.

Contents

A Giant Factory Complex

The Rouge complex is truly massive, stretching about 1.5 miles (2.4 km) wide and 1 mile (1.6 km) long. It has 93 buildings with almost 16 million square feet (1.5 km2) of factory space.

This huge complex had its own docks on the dredged Rouge River, so ships could bring in materials. It also had 100 miles (160 km) of its own railroad tracks, its own power plant, and even an integrated steel mill. This meant that raw materials could arrive at one end and leave as a finished car at the other! This way of working is called vertical integration.

Some of the buildings at the Rouge were designed by Albert Kahn. For example, his glass plant at the Rouge was known for being a great place to work. It had lots of natural light coming in through windows in the ceiling. In recent years, some buildings at the Rouge have been updated to be more "green" and environmentally friendly.

In 1932, a famous Mexican artist named Diego Rivera visited the Rouge complex. He studied the factories and used what he saw to create his famous murals called Detroit Industry.

What Was Made at the Rouge

The very first things made at the Rouge plant were Eagle Boats. These were World War I boats used to fight submarines. After the war, the factory started making Fordson tractors.

Even though the Rouge made almost all the parts for the famous Ford Model T, the final assembly of that car happened at another Ford plant called Highland Park. It wasn't until 1927 that cars were fully assembled at the Rouge, starting with the Ford Model A.

During World War II, the Rouge complex was very important for the war effort. It produced jeeps, airplane engines, airplane parts, tires, armor plates, and tractors.

Over the years, many other famous Ford vehicles were made at the Rouge. These included the 1932 Model B, the original Mercury cars, the Ford Thunderbird, Mercury Capri, and many generations of Ford Mustangs.

For a long time, the River Rouge complex made most of the parts for Ford vehicles. Many of these parts were put into "knock-down kits" and sent by train to other assembly plants across the United States. After the 1960s, Ford started building more factories in different cities. The Rouge complex became smaller, and some of its parts, like the famous furnaces, were sold to other companies.

In 1937, there was a disagreement between workers and the company about forming a union at the Rouge. This event is sometimes called the Battle of the Overpass.

The Rouge was one of only three places where Ford made the Mustang car. By 1987, only Mustang production remained at the Dearborn Assembly Plant (DAP) within the Rouge complex. Ford had planned to replace the Mustang with a different car, the Ford Probe, but people loved the Mustang so much that sales went up, and the Rouge plant was saved!

Ford decided to modernize the plant. Sadly, in 1999, a gas explosion at the power plant killed six employees. A new, modern power plant was built nearby to provide electricity and steam. The historic Dearborn Assembly Plant closed on May 10, 2004, with a red 2004 Ford Mustang GT being the last car built there. The old plant was taken down by 2008.

The Ford Rouge Center Today

Today, the Rouge site is known as the Ford Rouge Center. It's an industrial park with six Ford factories on 600 acres (2.4 km2) of land. There are also steelmaking operations run by another company.

The new Dearborn Truck factory at the Rouge is famous for its special green roof. This roof is covered with plants and helps collect and clean rainwater. It was designed by a sustainability architect named William McDonough. The Rouge Center is still Ford's largest factory and employs about 6,000 workers. However, Mustang production has moved to another plant in Flat Rock, Michigan.

Tours of the Rouge complex have been a long tradition. Free bus tours started in 1924 and ran until 1980, with about a million visitors each year at their peak! The tours started again in 2004 with The Henry Ford Museum. Visitors can see multimedia shows and even watch the assembly line. In 2017, 148,000 people visited the Ford Rouge Factory Tour.

Workers at the Ford and steel facilities at the Rouge are part of the UAW Local 600 union.

Ford used to have a fleet of three Great Lakes freighters based at the River Rouge Plant. These ships were named after Ford family members and later company leaders. The top part of one of these ships, the SS Benson Ford, was moved to Ohio and turned into a private home!

In 2020, Ford announced they would build the new Rouge Electric Vehicle Center. This is where their electric vehicles will be made. In 2021, the center opened, and Ford's first all-electric truck, the Ford F-150 Lightning, is the first vehicle produced there.

Green Architecture at the Rouge

In 1999, architect William McDonough worked with Ford to redesign parts of the Rouge River facility. The roof of the Dearborn truck assembly plant, which is 1.1-million-square-foot (100,000 m2) big, was covered with more than 10 acres (4.0 ha) of sedum. Sedum is a low-growing plant that helps the roof in several ways.

The sedum retains and cleans rainwater, and it also helps keep the building cooler in summer and warmer in winter, saving energy. This special roof is part of an $18 million system that collects and cleans rainwater every year. This system saved Ford from having to build a much more expensive water treatment facility.

Current Products Made

- Ford F-150 (1948–present)

- Ford F-150 Lightning electric pickup (2022–present)

Past Products Made

- Eagle-class patrol craft (1918–1919)

- Fordson tractor (1921–1928)

- Ford Model T parts only (1920s)

- Ford Model A (1927–1932)

- Ford Model B (1932–1934)

- Ford Model 48 (1935–1936)

- 1937 Ford (1937–1940)

- 1941 Ford (1941–1942, 1946–1949)

- 1949 Ford (1949–1951)

- 1952 Ford (1952–1954)

- Ford Fairlane (1955–1961)

- Ford Thunderbird (1955–1957)

- Ford Mustang (1964–2004)

- Mercury Capri (1979–1986)

- Mercury Cougar (1966–1973)

See also

In Spanish: Ford River Rouge Complex para niños

In Spanish: Ford River Rouge Complex para niños