Steel mill facts for kids

A steel mill or steelworks is a huge factory where steel is made. Steel is a very strong metal. It is an alloy, which means it's a mix of two or more metals, or a metal and another element. In steel's case, it's mostly iron mixed with a little bit of carbon. Steel is used to build many things, like cars, bridges, and tall buildings.

Contents

How Steel is Made

Making steel is a big job that usually happens in two main steps. First, we get a basic form of iron, and then we turn that iron into strong steel.

From Iron Ore to Pig Iron

The journey of steel starts with iron ore, which is a rock found in the ground that contains iron. To get the iron out, the ore is heated up in a giant oven called a blast furnace.

- Heating the Ore: Inside the blast furnace, the iron ore is mixed with two other important things:

* Coke: This is a special type of fuel made from coal. It burns very hot and helps remove oxygen from the iron ore. * Limestone: This rock helps to clean out unwanted stuff, called impurities, from the iron.

- Making Pig Iron: When these materials are heated together, the iron ore melts. The iron separates from the impurities. The melted iron that comes out is called pig iron. It's very hot, liquid iron.

Turning Pig Iron into Steel

Pig iron is strong, but it's also brittle, meaning it can break easily. To make it into steel, we need to make it tougher and more flexible.

- Removing Impurities: The liquid pig iron still has some unwanted materials in it. These are carefully removed.

- Adding Special Elements: To make different types of steel, other elements are added. These are called alloying elements. Some common ones include manganese, nickel, chromium, and vanadium. Each element gives the steel special qualities, like making it stronger, more resistant to rust, or easier to shape.

- Molten Steel: After these steps, the pig iron has been transformed into molten steel, which is liquid steel ready for the next stage.

Shaping the Steel

Once the steel is made, it needs to be shaped into forms that can be used for building or manufacturing.

- Casting: The molten steel is poured into molds to create large, solid shapes. These shapes are called blooms, ingots, or slabs, depending on their size and form. This process is known as casting.

- Rolling: These solid steel pieces are then sent through powerful machines that squeeze and flatten them. This is called hot rolling because the steel is still very hot. It helps to make the steel even stronger and gives it the desired shape, like long sheets or beams. Sometimes, steel is also shaped using cold rolling, which happens at room temperature for a smoother finish.

After these steps, the steel is ready to be used to make countless products all around the world!

Images for kids

-

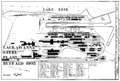

Plan of the Lackawanna Steel plant in Buffalo, New York around 1903, showing the different parts of a steel mill.