Willow Run facts for kids

Willow Run was a huge factory complex in Michigan. It was also known as Air Force Plant 31. The Ford Motor Company built it to make airplanes very quickly, especially the B-24 Liberator heavy bomber. Building the Willow Run Bomber Plant started in 1940 and finished in 1942.

Contents

Building Bombers for War

The factory started making things in the summer of 1941. At first, it only made parts for planes. Other companies like Douglas Aircraft and Consolidated Aircraft put the finished planes together.

But putting planes together from far away was hard. So, by October 1941, Ford got permission to build whole Liberator bombers. The Willow Run factory made Liberators until May 1945. It built almost half of all the Liberator bombers ever made!

Willow Run Airport

Willow Run Airport was built right next to the bomber factory. After the war, the airport became a civilian airport. Today, the Wayne County Airport Authority runs it.

Parts of the airport were also used for research by the University of Michigan. It was even a small United States Air Force base for a while. Willow Run Airport is still busy today. It handles cargo flights and planes for general use. Since 1992, it has been home to the Yankee Air Museum.

What Happened After the War?

Ford built the factory and sold it to the government. Then, they rented it back to use during the war. After the war, Ford decided not to buy the factory back.

The Kaiser-Frazer Corporation bought it instead. In 1953, Ford's competitor, General Motors, took over. GM used the factory to make car parts, like transmissions, until 2010. Another part of the complex, Willow Run Assembly, made cars from 1959 to 1992.

In 2009, General Motors announced it would close all its operations at Willow Run. Since 2010, the factory complex has been managed by the RACER Trust. This group takes care of old General Motors properties. Most of the factory was torn down in late 2013 and early 2014.

The name Willow Run also refers to a community near Ypsilanti. This community is roughly within the boundaries of the Willow Run Community School District.

History of Willow Run

Willow Run gets its name from a small stream that flowed through fields and woods. This was near the county line until the late 1930s. A local family, Quirk Farms, owned the land that became the airport. Henry Ford bought Quirk Farms in 1931.

Ford loved country life. He used the land for a special project called the "Willow Run Camp." City boys came to learn about farming, nature, and rural life.

Camp Willow Run

Boys at Camp Willow Run planted and harvested crops. They also collected maple syrup. They sold their products at a farm market on the property. This taught the boys self-discipline and the value of hard work. They also got to enjoy the fresh country air.

Camp Willow Run was for boys aged 17-19. Many were sons of soldiers who died or were hurt in World War I. The camp helped them learn to be self-reliant and manage things. The boys even governed themselves, choosing their own leaders. They lived in tents and had a mess hall and a chapel. They sold their produce from a roadside stand.

The boys also had time for fun. Each camp had a baseball field. They played softball, volleyball, and handball. They watched movies and had harvest dances with local high school students. Camp Willow Run closed after the 1941 season. Many boys then went to work at the new bomber plant.

The Chapel of Martha and Mary

Henry and Clara Bryant Ford built several churches. They called them the chapels of Martha and Mary. These chapels honored their mothers, Mary Ford and Martha Bryant. They built seven chapels in total. The first was in Greenfield Village, Michigan in 1929.

The Willow Run Chapel was built for Camp Willow Run. After the war, it was sold several times. In 1979, it became the worship place for the Belleville Presbyterian Church.

The Willow Run Chapel is now a few miles from its original spot. It is on land that Henry Ford once owned. It is the only one of the seven chapels still used as a regular church. It still has its original pews and other furniture.

From Farm to Flight Line

During World War II, almost all US factories helped with the war effort. The Ford Motor Company, led by Henry Ford's son Edsel, focused on making things for the Allied forces.

In early 1941, the government started a program to build many B-24 bombers. Ford joined this program. Ford would not only build the bombers but also provide the airfield. The farm at Willow Run was perfect for runways. Henry Ford owned it, so there were no land problems. It was also between major roads and train lines.

Henry Ford still had a say in the company. He refused government money to build the factory. He wanted his company to build it and then sell it to the government. The government would then rent it back to Ford during the war. Ford had the first chance to buy the plant after the war. But they chose not to.

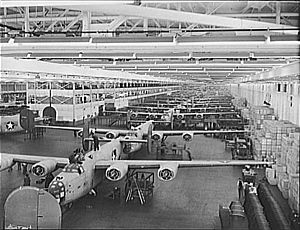

The architect Albert Kahn designed the main bomber plant. It had 3,500,000 square feet (325,160 square meters) of factory space. The assembly line for aircraft was over a mile (1600 meters) long. It was thought to be the largest factory under one roof in the world.

The Willow Run plant had a large turntable on the assembly line. This allowed the B-24 production line to turn 90 degrees. This helped the planes move to the final assembly area.

Housing for Workers

Willow Run needed many workers. This led to a huge housing shortage. People drove long distances or rented every spare room. Because housing was so urgently needed, the Federal Public Housing Administration built temporary homes.

Willow Run Lodge and Village

Housing complexes were built in different areas. Willow Run Lodge had dormitories for single people. It opened in February 1943. It had 15 buildings with 1,900 rooms for 3,000 people.

Between June and December 1943, temporary "flat-top" buildings were finished. These provided homes for 2,500 families. This area was called Willow Run Village. The flat-tops had four, six, or eight apartments. These apartments had one, two, or three bedrooms.

The Willow Run Village also had "West Court" buildings. These had peaked roofs and space for couples or three adults. Some of these apartments had no bedrooms, called "zero bedroom" apartments. The rest had one bedroom. Another large dormitory, West Lodge, was also ready for tenants.

By the end of 1943, there were six different temporary housing projects near Willow Run. They included dorms, trailer parks, and apartments. Together, they housed over 15,000 people. This was about the same number of people living in Ypsilanti at that time.

Parkridge Homes

Another community called Parkridge Homes was built in 1943. It was for African-American Willow Run employees. Efforts to create mixed-race housing were not approved. So, a famous African-American architect, Hilyard Robinson, designed an 80-unit community.

These homes were used as public housing until 2016. Then, they were torn down and rebuilt with new, modern units. In May 2017, Parkridge Homes received three historic markers. These markers show its importance to Ypsilanti's history. The Parkridge Community Center was also built at this time.

Making Liberator Bombers

When the plant first opened, there were some problems. Quality was not always good. Ford had made cars for a long time but had not built planes since the 1920s. At first, Ford was only supposed to make parts for the B-24. Other companies would put them together.

But in October 1941, Ford got permission to build complete Liberators. Still, it took almost a year for the first finished planes to leave the factory.

A report in 1943 criticized the plant. It said Ford built the production line too much like a car assembly line. This was despite warnings from experienced aircraft builders.

However, bringing car-making ideas to planes also led to amazing production rates. The plant was the world's largest enclosed "room." The first Ford-built Liberator rolled off the line in September 1942. This first series was called the B-24E.

The Willow Run Plant had many early problems. Ford workers were used to making cars very fast. It was hard to use those same methods for planes. The factory also had problems with workers. Many people were absent, and workers often left their jobs. The factory was far from Detroit. Wartime limits on gas and tires made it hard to get to work. In one month, Ford hired 2,900 workers but lost 3,100.

Also, Henry Ford was difficult and set in his ways. He was against unions, which led to big worker problems, including a large strike. At first, Henry Ford refused to hire women. But he finally allowed "Rosie the Riveters" to work on his assembly lines. This was probably because so many men were fighting in the war.

By late 1943, Mead L. Bricker took over the top leadership role at Willow Run.

The government asked Ford to spread out its operations. Many parts were made at other Ford plants and by other companies. The Willow Run plant then focused on putting the final aircraft together. Eventually, the problems were solved. By 1944, Ford was making a Liberator every 63 minutes, 24 hours a day, 7 days a week.

At its busiest (August 1944), Willow Run made 428 B-24s in one month. Ford built 6,972 of the total 18,482 B-24s. They also made parts kits for 1,893 more planes. The B-24 is the most produced heavy bomber in history.

How Planes Were Prepared for War

After planes were made, they needed to be sent to squadrons. This was done by the 1st Concentration Command (1st CC) at Willow Run. This group made sure squadrons had everything they needed before going overseas. They also did a final check of the planes. They added things like extra fuel tanks or removed unneeded equipment. They also did a final flight safety test.

While planes were being prepared, the flight crews were also processed. Pilots, co-pilots, navigators, and crew chiefs were assigned to each plane. They waited on cots for the B-24s to be ready. They also got paperwork done and received special equipment. Some training for supporting the aircraft was also given.

It was hard to add new changes to the planes quickly. These changes came from experiences in battles overseas. So, new Liberators often needed changes for the specific areas where they would fight. Special centers were set up to make these changes after the planes were built.

Types of Liberators Made at Willow Run

The B-24E was the first type of B-24 made by Ford at Willow Run. Ford built 490 complete planes. They also sent parts kits for 144 planes to Fort Worth and 167 to Tulsa for final assembly.

B-24Es built at Ford were called B-24E-FO. Those put together in Tulsa or Fort Worth from Ford parts were called B-24E-DT and B-24E-CF. Because of delays at Willow Run, many B-24Es were outdated when they were finished. Most were used for training in the United States and did not see combat.

The B-24H was the first type made by Ford in large numbers that went into combat. The B-24H had a second gun turret in the nose. This gave it more defensive firepower. The first B-24Hs were delivered in late June 1943. Willow Run made 1,780 B-24H planes.

When the B-24J was introduced, all three Liberator factories started making this version. The B-24J had a power-driven tail turret and other gun changes in the nose. The bomber plant made its first B-24J in April 1944. Willow Run built 1,587 of these.

By June 1944, the Army decided that only the San Diego and Willow Run plants would be needed for Liberator production. This was because the Boeing B-29 Superfortress was taking over long-range bombing in the Pacific. No new B-24 units were planned for Europe or other areas.

The B-24L was an attempt to make the Liberator lighter. More weapons, equipment, and armor had made the plane heavier. But the engines had not gotten more powerful. With less weight and stronger engines, it could fly much farther. Willow Run built 1,250 B-24L aircraft.

The B-24M was the last large-scale Liberator model. It was very similar to the B-24L, but had a new tail turret. The first B-24Ms were delivered in October 1944. By 1945, Willow Run had built 1,677 of them.

Ford had started making the single-tailed B-24N in May 1945. But the war in Europe ended that same month. This quickly stopped Liberator production. Ford's contract was ended on May 31, 1945. Orders for 5,168 unbuilt B-24N-FO bombers were canceled. The delivery of seven YB-24Ns by Ford in June 1945 marked the end of Liberator production at Willow Run.

What Happened After the War?

Ford had the chance to buy the plant after the war. But they decided not to. This ended their connection with Willow Run.

Kaiser Takes Over

After Ford declined, the plant was sold to the Kaiser-Frazer Corporation. This was a partnership between Henry J. Kaiser, who built ships, and Joseph W. Frazer. The plant made both Kaiser and Frazer (automobile) cars. It also made the small Henry J car. This car was also sold by Sears-Roebuck as the Allstate.

Willow Run made 739,000 cars for Kaiser-Frazer and Kaiser Motors. This was from 1947 to 1953. After losing money for years, the company bought Willys-Overland. They moved their car production from Willow Run to the Willys plant in Toledo, Ohio.

Willow Run is famous for the Liberator bomber. But B-24s were not the only planes made there. During the Korean War, the United States Air Force needed more cargo planes. Kaiser-Frazer built C-119 Flying Boxcar cargo planes at Willow Run. They made about 88 C-119s between 1951 and 1953. Kaiser also built two C-123 Provider plane bodies at Willow Run. But these were scrapped before delivery.

General Motors Operations

Later in 1953, a fire destroyed General Motors' factory in Livonia, Michigan. So, the Willow Run complex was first rented to GM, then sold to them. GM moved their car part machinery to Willow Run. They started making parts again just nine weeks after the fire.

Over the years, GM made the bomber plant about half bigger. It became a nearly 5,000,000 square foot (464,515 square meter) GM Powertrain factory. A piece of land south of the factory was used for car assembly starting in 1959. This included a Fisher Body plant that built car bodies for Chevrolet models. These included the Corvair and Nova. Cars were made there until 1992.

Besides making automatic transmissions, Willow Run also made M16A1 rifles and M39A1 20mm autocannons for the US military during the Vietnam War.

By the time General Motors went bankrupt in 2009, very little was being made at Willow Run. The GM Powertrain plant closed in December 2010. The complex then went to the RACER Trust. This group is in charge of cleaning up and selling old GM properties.

Research at Willow Run

On the other side of the airport were some old World War II hangars. These were sold to the University of Michigan in 1946. The university ran the Michigan Aeronautical Research Center (MARC) there. Later, it was called Willow Run Laboratories (WRL). This lasted from 1946 to 1972.

MARC and WRL made many new discoveries. These included the first ruby laser and work on the ruby maser. They also did early research on missile defense and advanced remote sensing. In 1972, the university spun off WRL into a new group. This group eventually moved to Ann Arbor.

Saving a Piece of History

The airport is still called Willow Run Airport. It is owned by the Wayne County Airport Authority since 2004. It is mainly used for cargo and general aviation flights. The Yankee Air Museum is located on the airport grounds. As of April 2013, it uses a 47,000 square foot (4,366 square meter) hangar.

In April 2013, the Detroit Free Press reported that the RACER Trust was talking with the Yankee Air Museum. The museum wanted to save a small part of the original bomber plant. This would be a new home for the museum. The museum needed to raise money to buy and separate a part of the huge building. This part was about 175,000 square feet (16,258 square meters). It is less than 5% of the original factory. It includes the end of the B-24 assembly line. It also has the two famous bay doors where the finished bombers left the plant during World War II.

The campaign to save part of Willow Run for the Yankee Air Museum was called SaveTheBomberPlant.org. It used a fundraising website. The campaign got attention from news groups all over the world. These included major US newspapers, National Public Radio, The History Channel magazine, National Geographic TV, and UK newspapers like The Guardian and the Daily Mail.

The RACER Trust extended the fundraising deadline several times. The final deadline was May 1, 2014. The museum needed to raise $8 million. Most of this money was for separating the museum's part of the building. This would make it a standalone structure. The RACER Trust supported the campaign. They even changed their demolition plans to help the museum save money.

By the May 1, 2014, deadline, the Yankee Air Museum had raised over $7 million. This was enough for the building owners to sign a purchase agreement with the museum. The actual purchase was expected to be completed in late summer or fall of 2014.

The rest of the Willow Run property, over 95% of the original bomber plant, was offered for redevelopment. It was planned to be a research and test facility for connected cars. But that plan did not happen. The property is still available for purchase and redevelopment.

Tearing Down the Factory

A reporter toured the empty Willow Run factory in early 2013. She noted that taking apart the plant was very hard. Copper wires and electrical parts had to be removed first. Every light bulb had to be taken out before the building could be torn down.

It cost a lot to keep the closed plant standing. It was $7 million each year. The person in charge of taking down the factory found it was like detective work. Managing the utilities and slowly turning them off was the biggest challenge. The building kept many secrets.

Toilets kept flushing automatically in many bathrooms. Water kept flowing through pipes to unknown places. Water even fell from the ceiling in some spots. The valves to turn off the water were hidden deep inside the building. The plant was designed to keep working even if parts were bombed. This meant it had separate water, air, and gas lines to different areas.

Demolition of most of the Willow Run factory began in December 2013. The Yankee Air Museum was able to get control of about 144,900 square feet (13,461 square meters) of the plant. They plan to build a permanent home for the museum there. By mid-2014, most of the factory had been torn down and cleared.

|

| Valerie Thomas |

| Frederick McKinley Jones |

| George Edward Alcorn Jr. |

| Thomas Mensah |