Materials science facts for kids

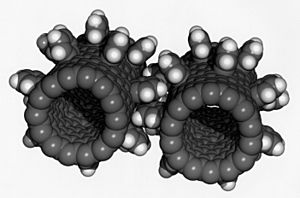

Materials science is a field that looks at the properties of different materials. It helps us understand why things are strong, light, or flexible. Scientists and engineers use this knowledge to solve problems and create new things. This field combines ideas from physics and chemistry. Recently, tiny materials, studied in nanotechnology, have become very important. Materials scientists also study why things break or wear out, which is key for making safer and more durable products.

Contents

A Look Back at Materials

Throughout history, the most important material of an era often gave the time its name. Think of the Stone Age, when people used stone tools, or the Bronze Age and Iron Age, when new metals changed how people lived.

Materials science first focused on ceramics (like pottery) and metallurgy (working with metals). These skills are very old, making materials science one of the oldest forms of engineering. A big step forward happened in the late 1800s. A scientist named Josiah Willard Gibbs showed that a material's physical properties are linked to its atomic structure. This means how the tiny atoms are arranged affects how the material behaves.

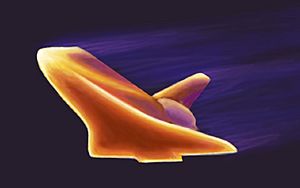

Modern materials science grew a lot during the Space Race. Scientists needed to understand and create special metal alloys, silica, and carbon materials. These were needed to build vehicles that could travel into space.

Today, materials science helps us develop many things. This includes plastics, semiconductors (used in electronics), ceramics, polymers, magnetic materials, and even materials for medical implants and biological uses.

Materials scientists also learn how to get materials from the Earth and turn them into useful forms. This involves processes like ingot casting, foundry techniques, and blast furnace extraction. Even tiny amounts of other elements can greatly change a material's final properties. For example, steels are grouped by how much carbon they contain. The way iron is taken from the ground affects the quality of the steel made from it.

Why Materials Fail

Studying big accidents in the 1800s and 1900s led to important discoveries. A.A. Griffith found that real materials are never as strong as they should be in theory. This was a huge finding! For instance, steel is only about one-tenth as strong as it could be. Most other solids are 100 to 1000 times weaker than expected.

J.E. Gordon built on Griffith's ideas. He said that simple solids are naturally brittle (they break easily). To make materials tough (resistant to breaking), we have to design that toughness into them. One common way is to add other materials to a pure substance. This makes its structure more complex, which helps it resist breaking.

A great example is bulletproof glass. It has a plastic layer stuck to glass. This makes it much stronger than either material alone. Kevlar in personal armour is another example. Some natural materials, like bones and tree trunks, also have this built-in "give" before they break.

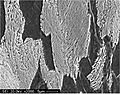

Metal Alloys

Studying metal alloys is a big part of materials science. Alloys are mixtures of metals, or a metal mixed with another element. The most common metal alloys used today are those made from iron. These include steel, stainless steel, and cast iron.

Steel is an iron alloy with a small amount of carbon, usually between 0.01% and 2.00%. The amount of carbon affects how hard and strong the steel is. More carbon makes steel harder but less flexible. Special heat treatments, like quenching and tempering, can change these properties a lot. Cast iron has more carbon than steel (2.00% to 6.67%). Stainless steel is a type of steel that contains more than 10% chromium, which helps prevent rust.

Other important metal alloys are made from aluminium, titanium, copper, and magnesium. Copper alloys have been used since the Bronze Age. But alloys of the other three metals are newer. This is because it was harder to get these metals out of their ores.

Alloys of aluminium, titanium, and magnesium are valued for being very strong but also very light. Magnesium alloys can also block electromagnetic signals. These materials are perfect for things like airplanes and some car parts, where being light and strong is more important than being cheap.

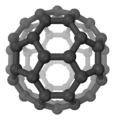

Polymers

Polymers are another key part of materials science. They are the basic materials used to make what we usually call plastics. Plastics are the final products, made by adding other things to polymers during processing. Then, the mixture is shaped into its final form.

Common polymers include polyethylene, polypropylene, PVC, polystyrene, nylons, and polyesters.

PVC (polyvinyl-chloride) is very popular because it's cheap and can be used for many things. It's used in artificial leather, electrical insulation, packaging, and containers. It's easy to make and can be mixed with different additives to give it various properties.

Ceramics and Glasses

Materials science also studies glass and ceramics. These are often known for being brittle (breaking easily). Ceramics and glasses are built using covalent bonds, often with silica (sand) as a main ingredient. Ceramics can be soft like clay or hard like stone and concrete. They usually have a crystalline structure.

Most glasses are made by melting a metal oxide with silica at high temperatures. When glass cools, it forms an amorphous structure, meaning its atoms are not arranged in a regular pattern. Windowpanes and eyeglasses are common examples. Even diamond and graphite (a form of carbon) are considered ceramics.

Engineered ceramics are known for being stiff, able to handle high temperatures, and stable under pressure and electrical stress. Materials like alumina, silica carbide, and tungsten carbide are made from fine powders pressed and heated together.

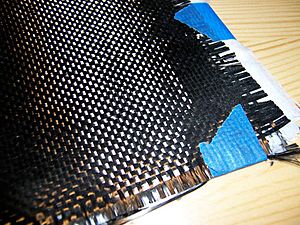

Composite Materials

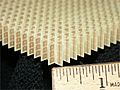

Another important area in materials science is making composite materials. These are materials made from two or more different parts that work together. They are used in many things, from steel-reinforced concrete in buildings to the special heat-resistant tiles on the Space Shuttle.

For example, the Space Shuttle thermal protection system uses a material called Reinforced Carbon-Carbon (RCC). This light gray material can handle extreme temperatures (up to 1510°C or 2750°F) when the shuttle re-enters Earth's atmosphere. RCC is made from layers of graphite cloth and a special resin. After heating, the resin turns into carbon. The outer layers are then changed into silicon carbide to protect against burning up.

You can also find composites in everyday items like the plastic cases of TVs and cell phones. These cases are usually a composite material. They might be a type of plastic like ABS mixed with things like calcium carbonate chalk, talc, glass fibers, or carbon fibers. These additions make the plastic stronger or give it other useful properties.

Types of Materials

Materials science covers many different types of materials. They are sometimes grouped by how their atoms are connected:

- Ionic crystals (like salt)

- Covalent crystals (like diamond)

- Metals (like iron or copper)

- Intermetallics (mixtures of metals with specific structures)

- Semiconductors (used in electronics, like silicon)

- Polymers (like plastics)

- Composite materials (like fiberglass)

- Vitreous materials (like glass)

- Callister, Jr., William D. (2000). Materials science and engineering – an introduction (5th ed.). Wiley. ISBN 0-471-32013-7.

- BBC News Science of materials. [1]

Images for kids

-

A diamond cuboctahedron showing seven crystallographic planes, imaged with scanning electron microscopy

-

A scanning electron microscopy image of carbon nanotubes bundles

-

Wire rope made from steel alloy

-

Google Ngram Viewer-diagram visualizing the search terms for complex matter terminology (1940-2018). Green: “materials science”, red: “condensed matter physics” and blue: “solid state physics”.

See also

In Spanish: Ciencia de materiales para niños

In Spanish: Ciencia de materiales para niños

| Anna J. Cooper |

| Mary McLeod Bethune |

| Lillie Mae Bradford |