Polypropylene facts for kids

Quick facts for kids Polypropylene |

|

|---|---|

|

|

|

|

| IUPAC name | poly(propene) |

| Other names | Polypropylene; Polypropene; Polipropene 25 [USAN]; Propene polymers; Propylene polymers; 1-Propene; [-Ch2-Ch(Ch3)-]n |

| Identifiers | |

| CAS number | |

| Except where noted otherwise, data are given for materials in their standard state (at 25 °C, 100 kPa) | |

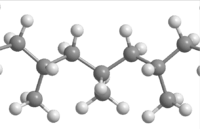

Polypropylene (PP), also called polypropene, is a very common type of plastic. It's a special kind of plastic called a thermoplastic polymer. This means it can be melted and reshaped many times.

Polypropylene can be made into thin fibres for clothes, films for packaging, or many other shapes. It can be clear or opaque, and often comes in bright colors. This plastic is tough and can resist many solvents, acids, and bases.

You might see it as a strong strap on backpacks or woven into fabric for clothing. It's the second most produced plastic in the world, right after polyethylene.

Contents

What Polypropylene is Used For

Polypropylene is used in many everyday items. Because it can bend many times without breaking, it's perfect for "living hinges." These are the thin plastic parts that connect a lid to a container, like on flip-top bottles.

Pipes and Plumbing

This plastic is used to make piping systems. These pipes can carry clean drinking water or be used in heating and cooling systems. Polypropylene is chosen because it doesn't rust or leak chemicals. It's also strong against damage like impacts or freezing. Workers can join these pipes by heating them, instead of using glue.

Containers and Household Items

Many plastic items for medical or lab use are made from polypropylene. This is because it can handle the high heat of an autoclave, which is a machine that sterilizes things. Its heat resistance also means it's used for consumer kettles.

Food containers made from polypropylene won't melt in the dishwasher. They also don't melt during industrial hot filling processes. This is why many plastic tubs for dairy products, like yogurt, are made of polypropylene.

Strong, clear, and reusable plastic containers, like those from Rubbermaid or Sterilite, are often made of polypropylene. Their lids are sometimes made of a softer plastic called LDPE, so they can snap on easily. Polypropylene is also used for disposable bottles, plastic pails, car batteries, and wastebaskets. Many medical devices are also made from this material.

Packaging and Bags

A common use for polypropylene is in something called biaxially oriented polypropylene (BOPP). These BOPP sheets are used to make clear bags. When polypropylene is stretched in two directions, it becomes very clear. This makes it a great material for packaging art and retail products.

Ropes and Fabrics

Polypropylene is used a lot in carpets, rugs, and mats because its colors don't fade easily. It's also widely used for ropes. Polypropylene ropes are special because they are light enough to float on water. They are also strong and cost less than most other synthetic ropes.

Electrical Cables

This plastic is also used as insulation for electrical cables. It's a good choice for places with poor air flow, like tunnels. This is because it creates less smoke and no toxic gases if there's a fire.

Molded Shapes and Sheets

Polypropylene is often used for plastic moldings. It's melted and injected into a mold to create complex shapes. This process is low-cost and can make many items quickly, like bottle tops and fittings.

It can also be made into sheets. These sheets are used for stationery folders, packaging, and storage boxes. They are durable, inexpensive, and resist dirt, making them ideal for protecting papers. Even Rubik's Cube stickers are made from polypropylene sheets!

Designers also use polypropylene sheets to create light shades. The plastic is light, durable, and colorful, allowing for creative, interlocking designs. Collectors of trading cards use polypropylene sheets with pockets to protect their cards.

Foam and Construction

Expanded polypropylene (EPP) is a foam version of polypropylene. EPP is great at absorbing impacts and returning to its original shape. Because of this, it's used a lot in model aircraft and other radio-controlled vehicles. It's a good material for beginners because it can handle crashes well.

Polypropylene fibers are added to concrete to make it stronger and reduce cracks. In places with earthquakes, these fibers are mixed with soil to improve its strength when building foundations for structures. The fibers are also used in drywall joint compound to make it more flexible and reduce shrinking when it dries.

Special Uses

In 2016, scientists found that a mix of polypropylene and special surfaces could repel liquids like shampoo and oil. This could help people get all the liquid out of bottles.

Clothing

Polypropylene is a main material in "nonwovens," which are fabrics not made by weaving. Over half of it is used for diapers or sanitary products. For these uses, it's treated to absorb water, even though it naturally repels it. Other non-woven uses include filters for air, gas, and liquids.

Polypropylene, or 'polypro', is used for cold-weather base layers, like long-sleeve shirts or long underwear. It's also used in warm-weather clothing because it moves sweat away from the skin.

It's important to know that while polypropylene clothes don't catch fire easily, they can melt. If someone wearing them is in a fire, the melting plastic could cause severe burns. Polypropylene underwear can also hold onto body odors, which are hard to wash out.

Some fashion designers have used polypropylene to make jewelry and other wearable items.

Medical

Its most common medical use is in a type of surgical suture called Prolene. This is a strong, non-dissolving thread used by doctors.

Polypropylene has also been used in operations to repair hernias. A small patch of the material is placed to help protect the body.

During the COVID-19 pandemic in 2020, the need for polypropylene grew a lot. This is because it's a key material for making the fabric used in face masks.

Niche Uses

Very thin sheets of polypropylene are used inside certain high-performance capacitors in electronics.

Expanded polypropylene (EPP) foam is a strong material for hobbyist radio control model aircraft. Unlike other foams that break easily, EPP foam can absorb impacts well. It keeps its shape and returns to normal quickly after a crash.

When the cathedral on Tenerife, La Laguna Cathedral, was repaired, its old parts were replaced with structures made of polypropylene. This was a new and large-scale use of the material in buildings.

Polypropylene rope is used to make scoop nets for fishing. It has also been used for yacht sails.

Polymer banknotes (plastic money) are made from BOPP. This makes the banknotes durable and allows for clear security features.

Recycling Polypropylene

Polypropylene can be recycled! It has the number "5" as its resin identification code. You can often find this symbol on plastic items to show what type of plastic they are.

Images for kids

-

Micrograph of polypropylene

See also

In Spanish: Polipropileno para niños

In Spanish: Polipropileno para niños

| Sharif Bey |

| Hale Woodruff |

| Richmond Barthé |

| Purvis Young |